Warp dyeing and multi-shaft winding process, warp dyeing and multi-shaft winding machine

A combined machine and winding mechanism technology, applied in warping machines, manufacturing tools, liquid/gas/vapor yarn/filament processing, etc., can solve the problems of many ends, large surface wear, and restricting the development of knitted denim.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

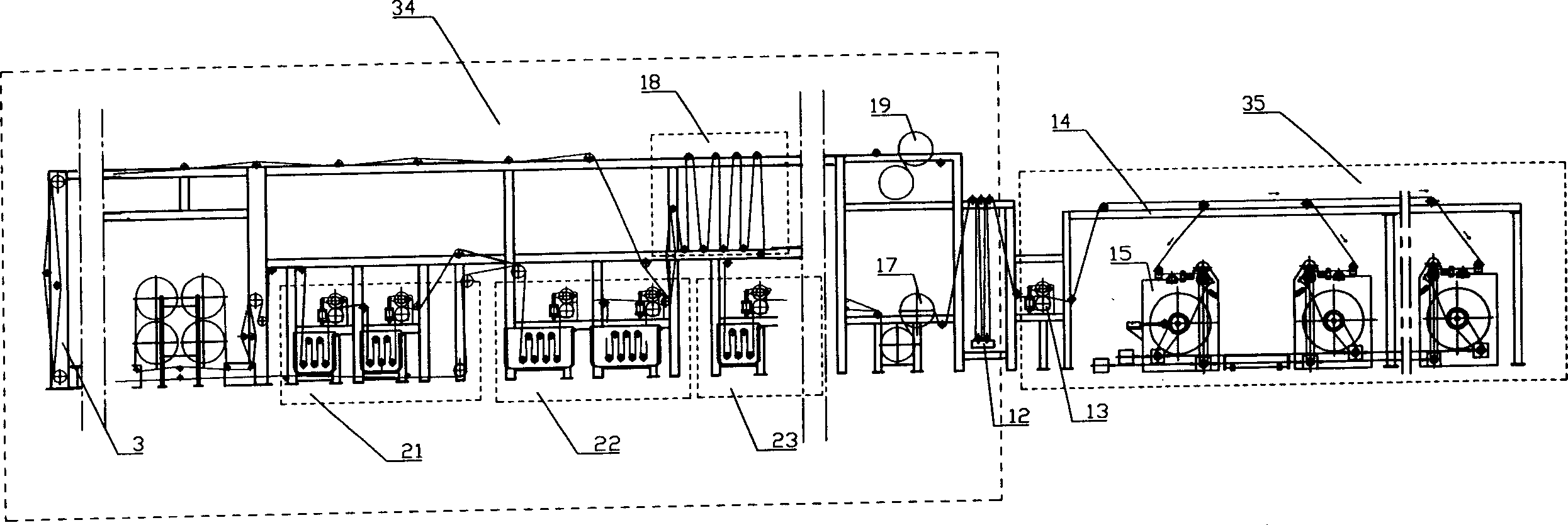

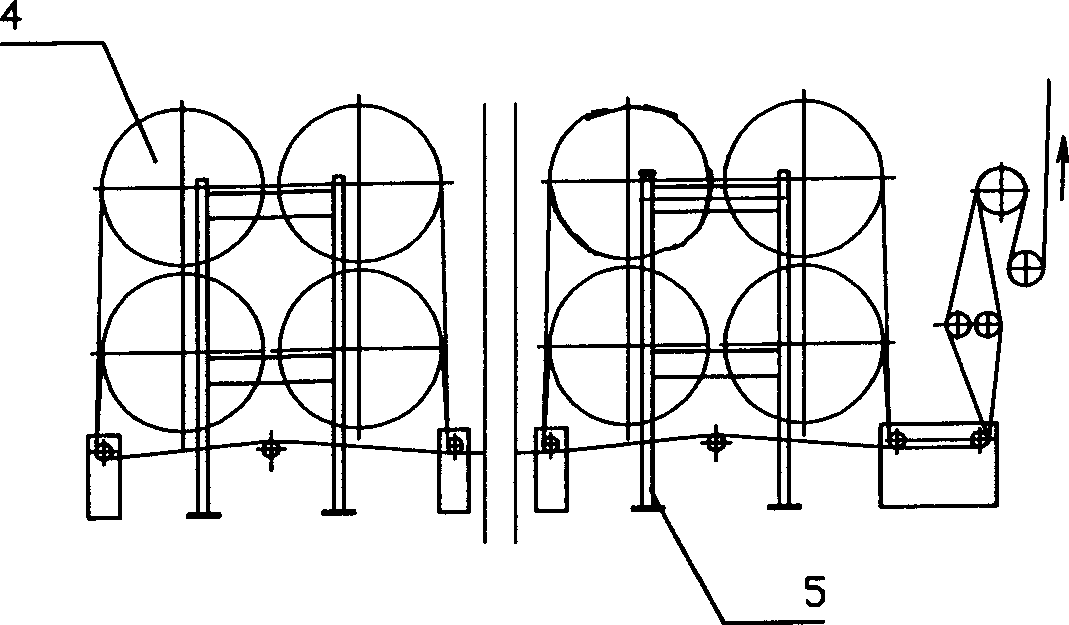

[0031] Such as figure 1 , 2 As shown, before dyeing, at first the package yarns to be dyed are evenly wound on the warp shaft 4 according to the head portion and length arrangement required by the warp yarn system through the disclosed warping machine, and then more than 8 warp yarns are warped The shaft 4 is placed on the warp beam support 5 in parallel, and the warp yarns that have been wound on the warp beam 4 are unwound in parallel and drawn out to be stacked into sheets successively.

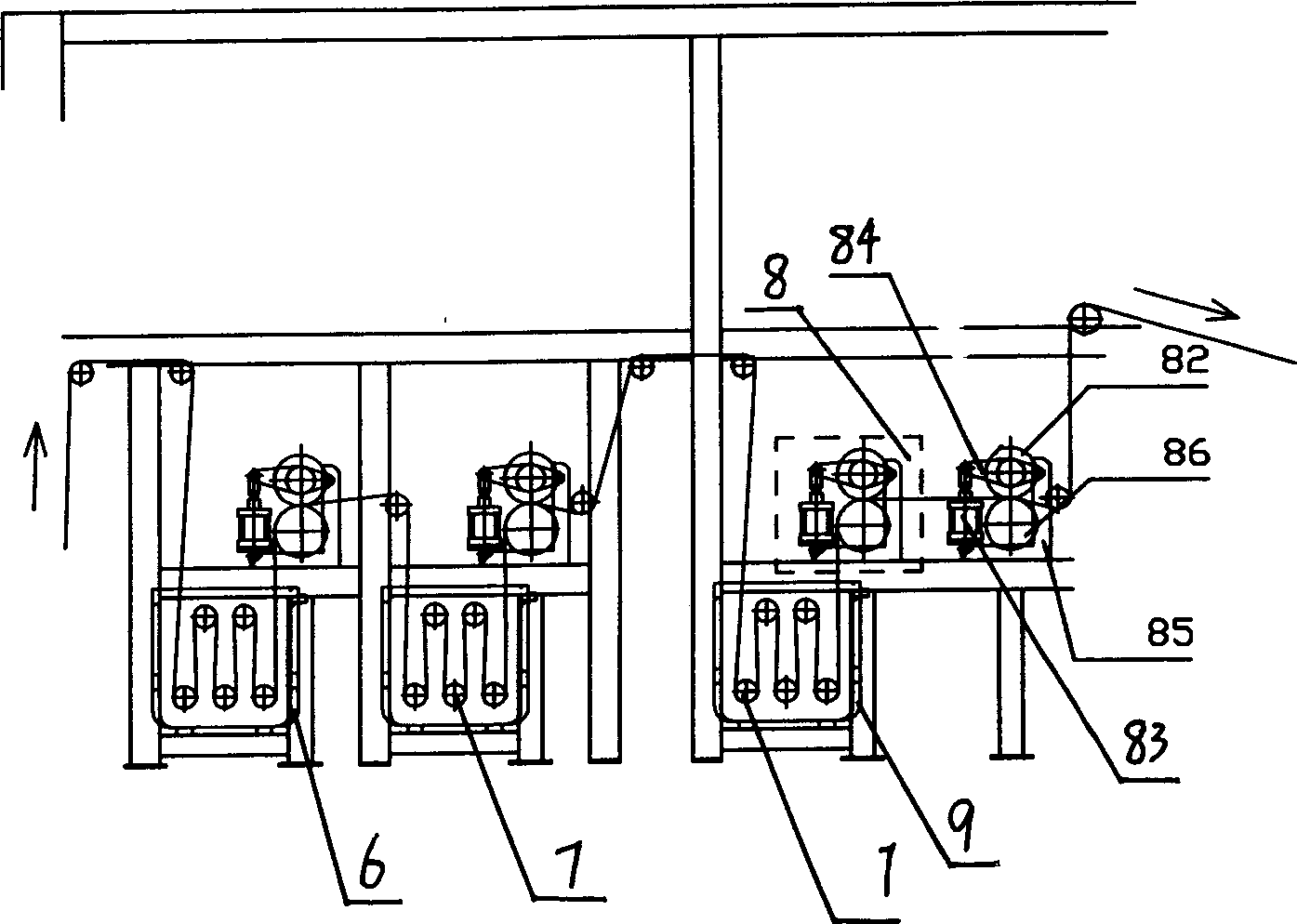

[0032] Such as figure 1 , 3 , 4, and 5, the laminated yarn is introduced into the scouring and washing device 21 through multiple guide rollers, and the scouring and washing device 21 is composed of two groups of scouring and washing tanks 6, and the yarn is passed through the first scouring and washing tank 6 The submerged roll 7 passes through the paddle car 8, and enters the submerged roll 7 and the paddle car 8 of the second scouring and washing tank 6 again to carry out the pre-dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com