Production method of figured cloth different from embroidery characteristics

A technology of jacquard fabric and production method, applied in the direction of excavation fabric, fabric, embossed fabric, etc., can solve the problems of poor three-dimensional effect of jacquard fabric, not very significant effect, limitation of warp yarn specifications, etc., and achieves strong three-dimensional effect and high production The effect of short time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

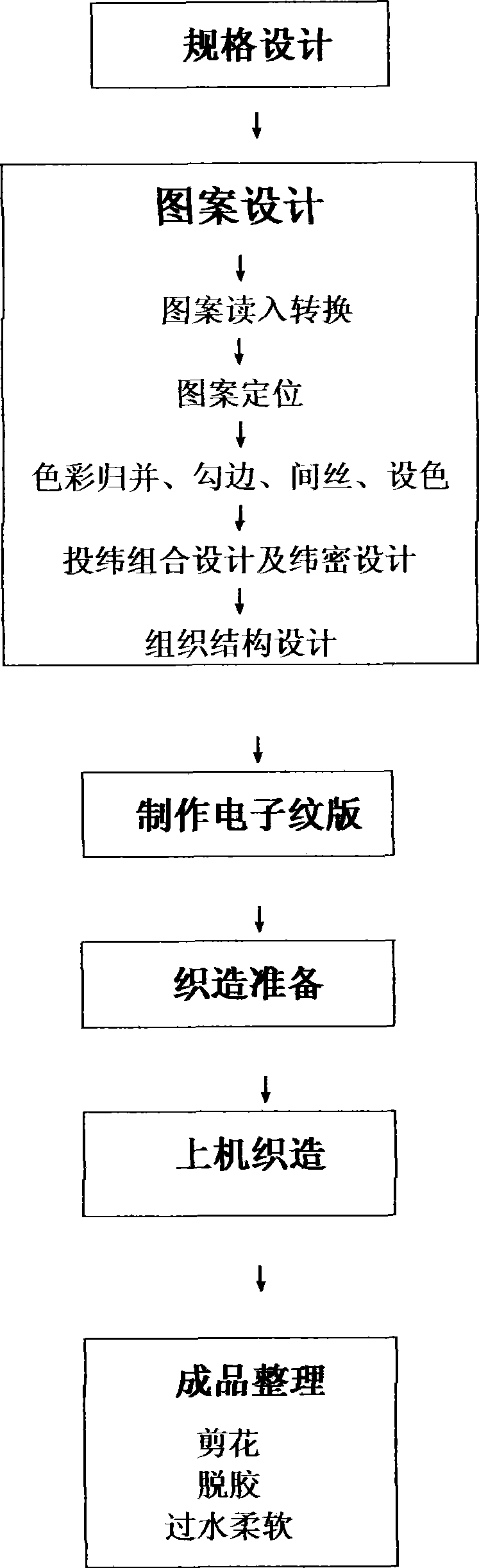

Method used

Image

Examples

Embodiment Construction

[0029] Now take the rose pattern fabric with a finished inner width of 141 cm as an example, which is applied to home textile decorative fabrics such as curtains and backrests. The width of the upper machine is 145 cm, and the width of each flower width is 36 cm. T / S (white), second warp: 4 / 20 / 22D mulberry silk 1.5T / S (yellow), designed to use 9600 warp yarns; a total of 6 sets of weft yarns are used, of which the first weft is 60S / 2 cotton yarn (rubber red) , the content percentage is 10.63%, B weft is 4 / 20 / 22D mulberry silk 1.5T / S (white), the content percentage is 30.5%, C weft is 60S / 2 cotton yarn (pink), the content percentage is 10.66%, D weft It is 60S / 2 cotton yarn (grass green), the content percentage is 20.59%, the penta weft is 60S / 2 cotton yarn (dark warp green), the content percentage is 20.35%, and the hexa weft is 4 / 20 / 22D mulberry silk 1.5T / S (yellow ), the content percentage is 7.2%. The first warp, second warp, second weft and hexyl weft form a yellow and whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com