Three-layer fabric and tatting technique thereof

A fabric and craft technology, applied in the field of three-layer fabric and its weaving technology, can solve the problems of cumbersome technology and unsatisfactory air permeability, and achieve the effects of simple weaving process, increased service life and air permeability, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

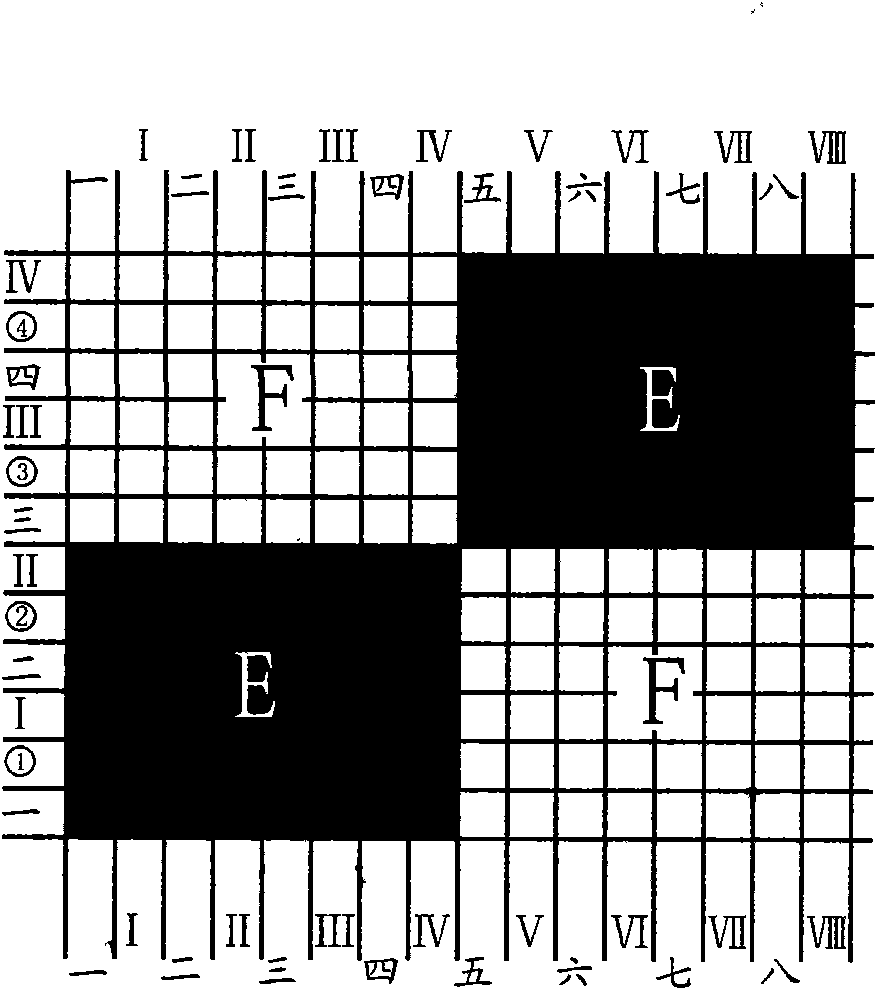

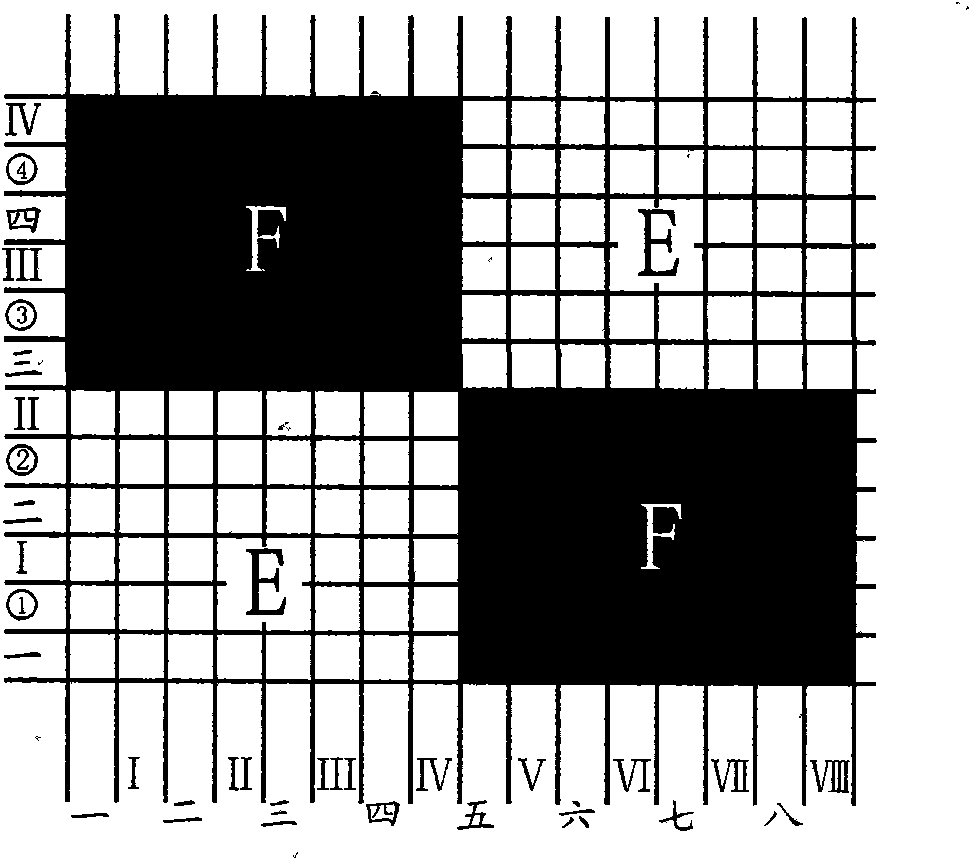

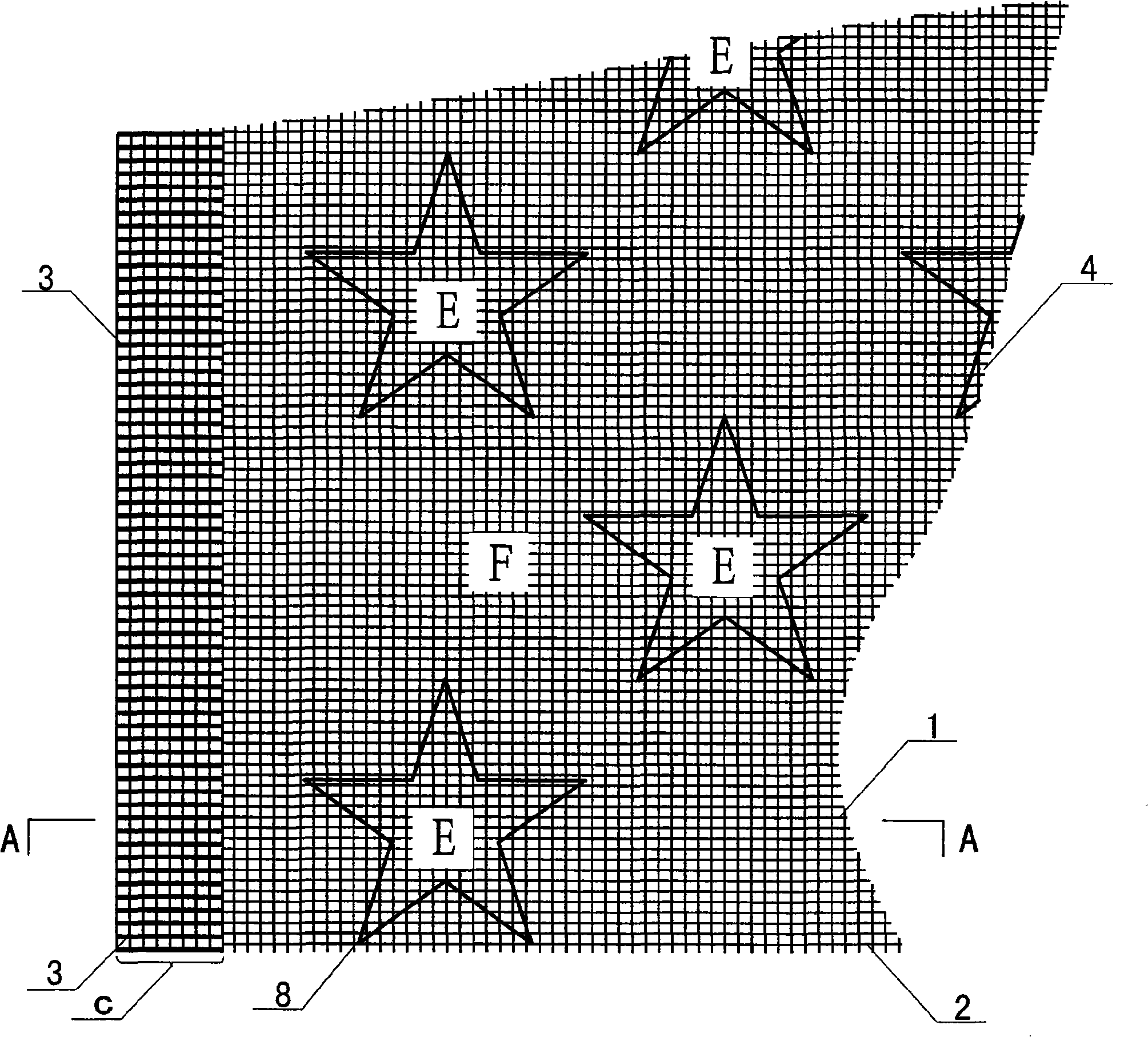

[0029] The three-layer fabric and its weaving process of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] For the convenience of observation and description, solid lines are used in some drawings of the present invention to represent the warp and weft yarns, and are drawn with relatively large intervals.

[0031] refer to figure 1 , 2, as shown in the figure, according to the process requirements of the aforementioned fabric design process, the three-layer fabric to be woven in this embodiment is designed to be a cloth with a checkered pattern on the surface and the inner layer and the plain weave weave on the surface and the inner layer; Both the outer and inner layers of the fabric are composed of pattern fabric E and basic fabric F. The complete pattern contains pattern fabric E in two regions, and their spacing in the warp direction is zero, that is, pattern pattern E in the lower left corner of the figure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com