Novel weaving process for printing and dyeing cloth

A process and new technology, applied in the field of new weaving process, can solve the problem of lack of color fixing function, and achieve the effect of simple and effective weaving process, good use effect and uniform distribution of color fixing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

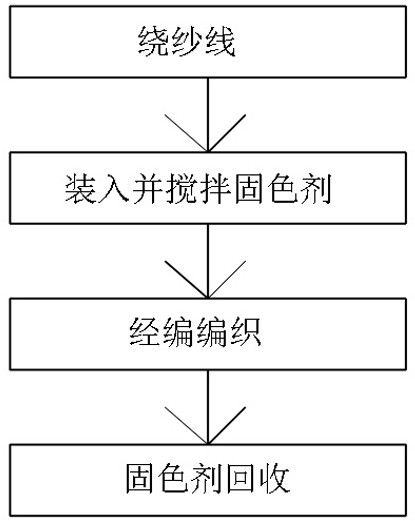

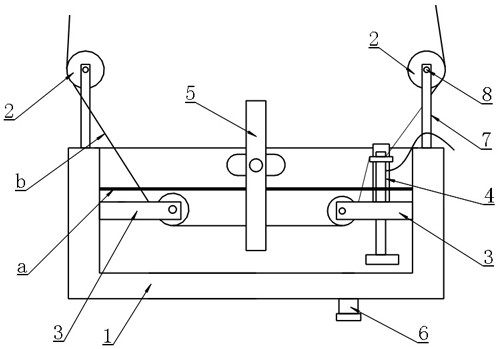

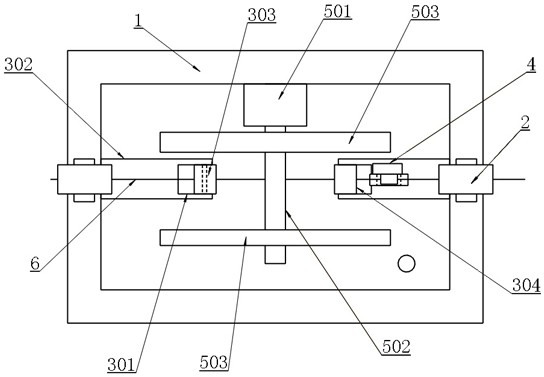

[0032] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Figure 6 As shown, a new weaving process for printing and dyeing cloth includes the following steps in sequence:

[0033] S1, yarn winding: wind the yarn on the color-fixing pretreatment machine and the warp knitting machine in turn;

[0034] S2. Load and stir the color-fixing agent: pour the color-fixing agent into the color-fixing pretreatment machine and keep stirring;

[0035] S3. Warp knitting: the warp knitting machine knits the yarns that have completed the color fixing operation to obtain warp knitting gray cloth;

[0036] S4. Recovery of color fixing agent: discharge and recycle excess color fixing agent in the color fixing pretreatment machine to complete a complete weaving process.

[0037] In S1, the end of the yarn is spun out, wound on the fixing ring of the color-fixing pretreatment machine, on the fixing ring of the warp knitting machine in turn, and finally fixed on the needle of the warp kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com