Novel concave-convex three-dimensional fabric and weaving method thereof

A three-dimensional, new technology, applied in the direction of textiles, papermaking, textiles, fabrics, etc., can solve the problems of poor three-dimensional effect of fabrics, reduction of three-dimensional effect, rigid clothing, etc., to achieve enhanced comfort, reduced floating length, high flower effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

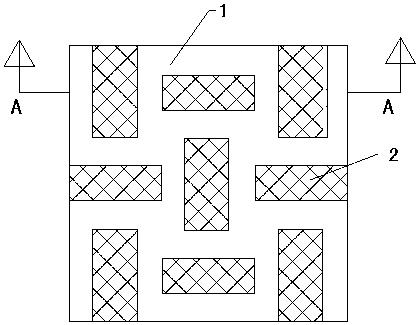

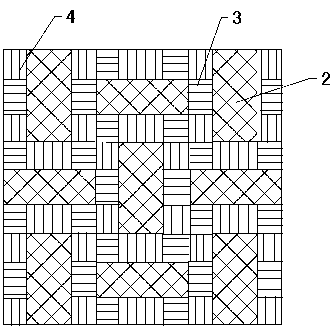

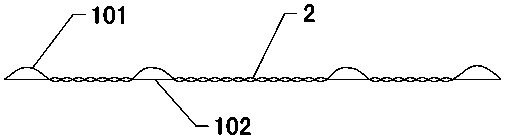

[0032] The new concave-convex fabric of this embodiment is composed of a convex part 1 and a concave part 2, the shape of the concave part 2 is a rectangle, and the adjacent rectangular concave parts are rotated 90 ° and arranged vertically, as figure 1 As shown, each rectangular concave portion 2 is surrounded by a convex portion 1, and the convex portion 1 and the concave portion 2 are all interwoven by warp threads and weft threads, and the warp threads include first warp threads and second warp threads , the weft includes a first weft, a second weft and a high-shrinkage yarn, the fineness of the first weft is greater than that of the second weft; the raised portion 1 is composed of a surface weave 101 and an inner weave 102, the surface weave 101 It is formed by interweaving the first warp and the second weft, and the inner weave 102 is composed of the weft float 3 formed by the first weft and the high-shrinkage yarn and the warp float 4 formed by the second warp, as figu...

Embodiment 2

[0042] The structure of the new concave-convex fabric of this embodiment is the same as that of Embodiment 1.

[0043] The present embodiment adopts dobby loom to weave, and weaving process comprises the following steps:

[0044] 1) Design pattern, yarn selection;

[0045] The pattern design of this example is the same as that of Example 1. The fabric of this example is woven from two sets of warp yarns and three sets of weft yarns. The two sets of warp yarns are dark blue cotton and linen blended yarns, and the three sets of weft yarns are high-shrinkage yarns of 400D nylon. Stretch yarn, white chenille yarn with 10Nm first weft and 50Nm double-ply cotton yarn with dark blue second weft;

[0046] 2) Design basic organization;

[0047]In this embodiment, the surface texture 101 of the raised part 1 and the texture of the concave part 2 are woven in a twill weave, and the inner layer texture 102 is the weft float 3 formed by the high shrinkage yarn and the first weft thread a...

Embodiment 3

[0052] The structure of the new concave-convex fabric of this embodiment is the same as that of Embodiment 1.

[0053] The present embodiment adopts dobby loom to weave, and weaving process comprises the following steps:

[0054] 1) Design pattern, yarn selection;

[0055] The pattern design and yarn type of this embodiment are the same as in Embodiment 1;

[0056] 2) Design basic organization;

[0057] In this embodiment, the surface weave 101 of the raised part 1 and the weave of the concave part 2 are woven in a variable plain weave, and the inner weave 102 is the weft float 3 formed by the high-shrinkage yarn and the first weft and the warp float formed by the second warp. long 4;

[0058] 3) Draw the cardboard diagram;

[0059] 4) Wearing healds and weaving on the machine; 12 healds for the cloth body and 2 healds for the edge;

[0060] 5) Heat treatment: adjust the temperature of the iron to 90°C, and iron the back of the fabric for 1.5 minutes to obtain a new conca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com