Manufacturing method of one-sheet type vamp

A manufacturing method and technology for shoe uppers, which are applied to shoe-making machinery, footwear, heel pads, etc., can solve the problems of high difficulty, low work efficiency, and poor appearance of shoe uppers, so as to simplify the manufacturing process and reduce manufacturing costs. Difficulty, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

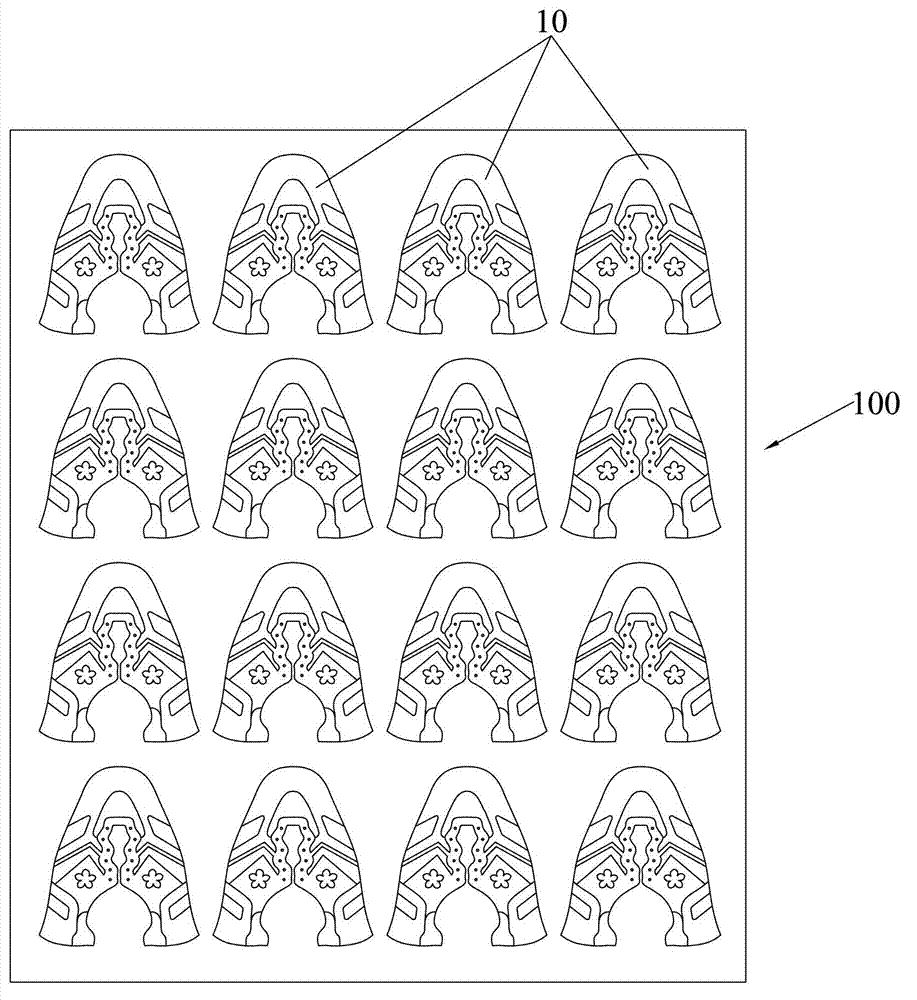

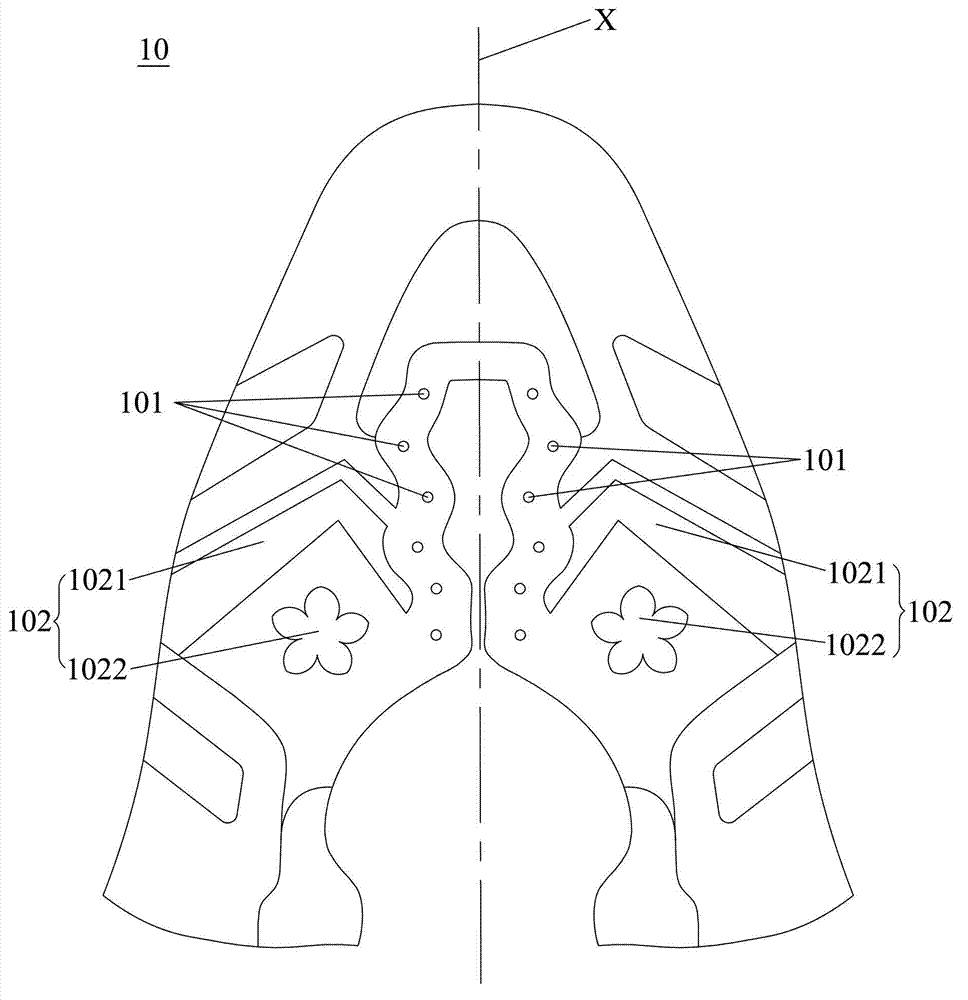

[0030] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

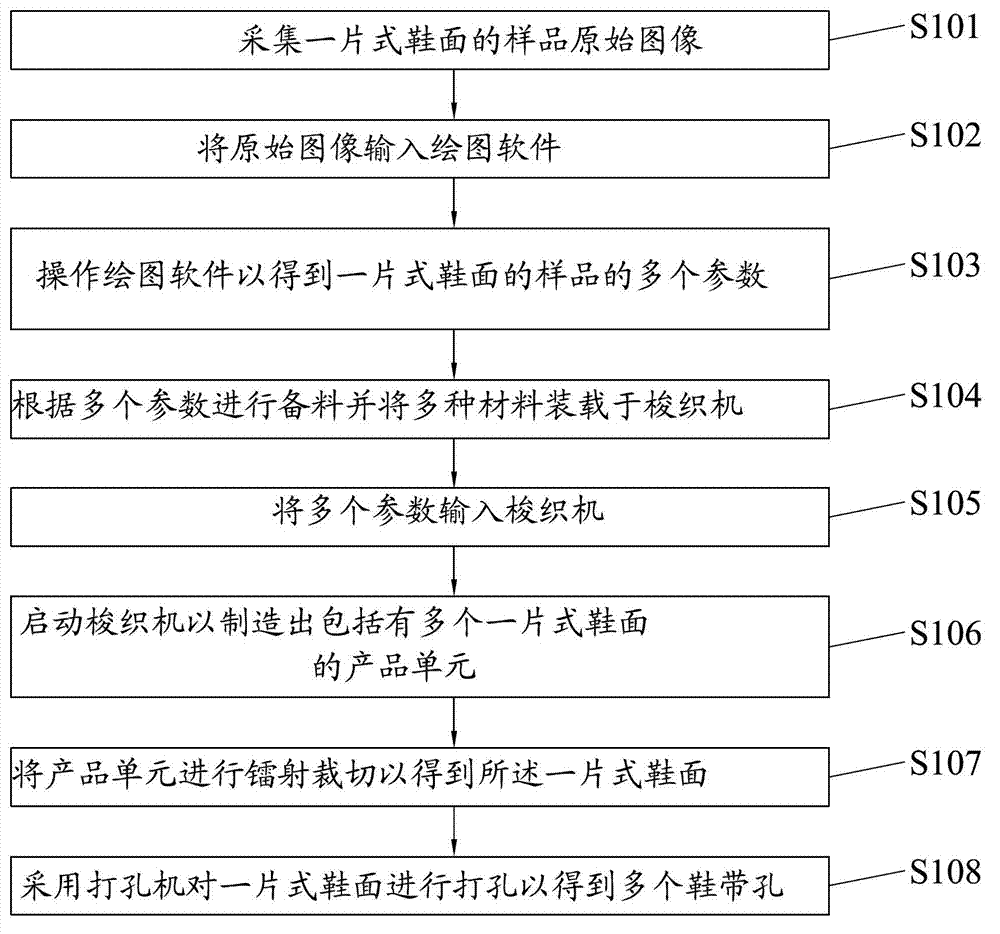

[0031] Please refer to figure 1 , the manufacturing method of one-piece vamp of the present invention mainly comprises the following steps:

[0032] S101, collect the original image of the one-piece shoe upper sample; usually, after receiving the shoe upper sample provided by the customer, the designer will use equipment such as a scanner or a camera to take an image of the shoe upper sample, that is, obtain the The original image;

[0033] S102, inputting the original image into drawing software;

[0034] S103, operate the drawing software to obtain multiple parameters of the one-piece shoe upper sample; the designer continuously adjusts the shape of the shoe upper sample and the pattern attached to the shoe upper sample by operating the drawing software. Shape, color and distribution position, etc., in order to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com