Large dense-weft jacquard gauze, clipped jacquard, colored woven cotton fabric

A jacquard and yarn-dyed fabric technology, applied in leno fabrics, leno fabrics, digging fabrics, etc., can solve the problems of yarn-dyed cotton singleness and difficulty in adapting to modern people's pursuits, and achieve strong three-dimensionality and hand feeling Smooth, soft and rich, fancy and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

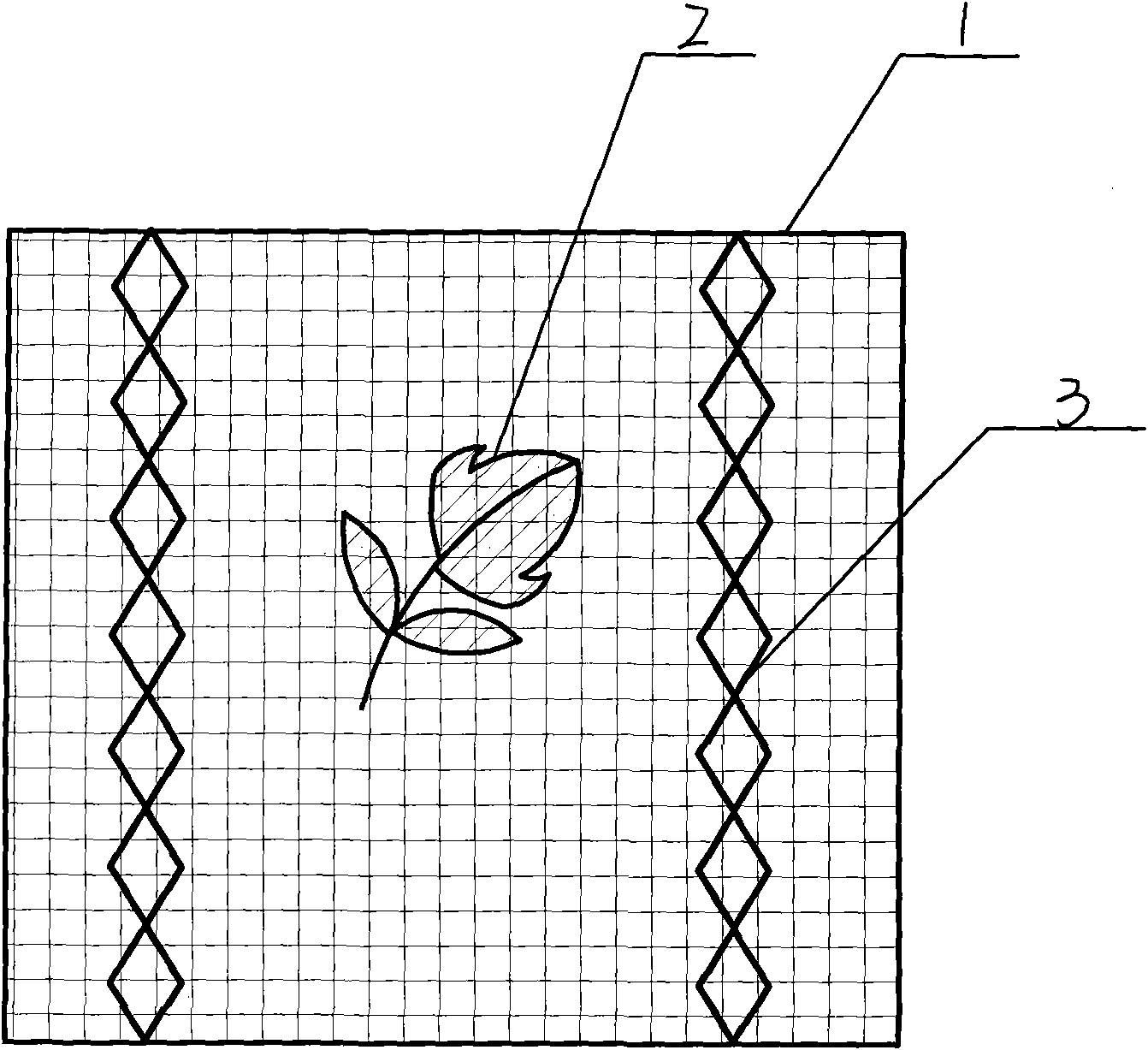

[0007] As shown in the figure, the yarn-dyed cotton fabric is composed of three parts: the bottom plain weave part 1, the cut pattern dense weft part 2, and the leno part 3. When weaving, the warp and weft threads of the yarn-dyed fabric are placed on the jacquard rapier loom, and the cloth is woven into cloth through the multi-weaving shafts of the jacquard rapier loom. During the weaving process, the bottom plain weave part 1, the cut pattern dense weft part 2 and the leno part 3 are carried out at the same time; the pattern of the cut pattern dense weft part 2 is formed by the circular turning of the jacquard plate, and the cut flower The dense weft part is 2 weaving a circle, and the dense weft section is formed by stopping the winding and stopping the warp feeding of the jacquard rapier loom, and the dense weft section formed thereby is 1-5 times larger than the dense section than the ground part, and the dense weft The system is accurate and stable, the flower pitch is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com