Silkworm pupa protein fiber blended yarns, moisture-absorbing suspension ultraviolet-resistant fabric, spinning method and production process

A technology of silkworm chrysalis protein fiber and blended yarn is applied in the fields of spinning method and production process, blended yarn, moisture-absorbing drape and anti-ultraviolet fabric, and achieves the effects of smooth surface, good wear resistance and improved weaveability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

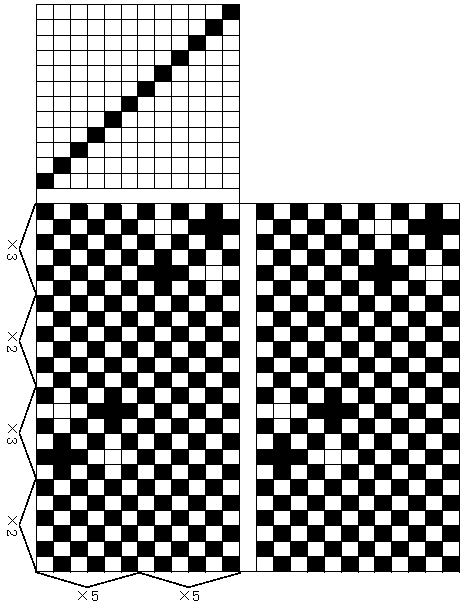

[0026] The invention discloses a silkworm chrysalis protein fiber blended yarn. The silkworm chrysalis protein fiber blended yarn is a silkworm chrysalis / polyester / cotton blended yarn, and the blended weight ratio of silkworm chrysalis / polyester / cotton is 50:25:25. The linear density of the spinning yarn is 14.8tex (tex specifically refers to the weight in grams of a 1000-meter-long yarn at a given moisture regain).

[0027] The invention also discloses the spinning method of the above-mentioned silkworm chrysalis protein fiber blended yarn. The method includes five processes in sequence. The ratio is 50:25:25;

[0028] The second process is carding, that is, carding the silkworm chrysalis protein fiber, polyester fiber and cotton fiber respectively. When carding, the process principle of "low speed, light weight, less fiber damage, more recovery, and proper tension" is adopted.

[0029] The third process is drawing. First, the silkworm chrysalis protein fibers and polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com