Preparation method of silk protein fibers

A silk protein fiber and silk protein technology, applied in the field of preparation of silk protein fiber, to achieve good hygroscopicity, improve air environment, smooth and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

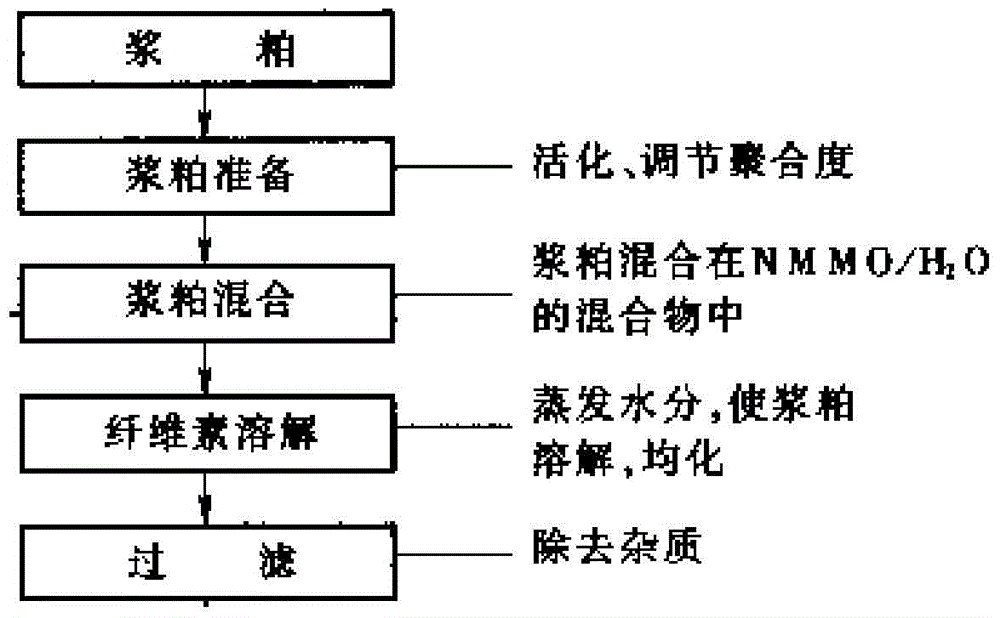

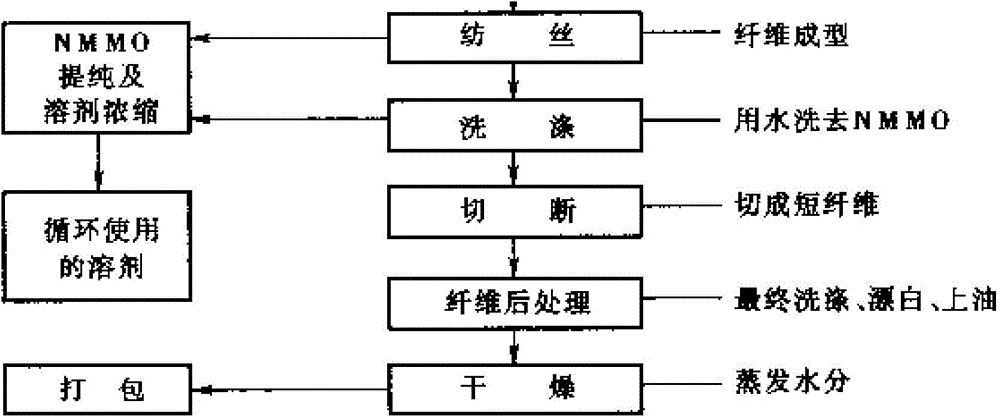

[0025] A kind of preparation method of silk protein fiber provided by the invention, it comprises the steps:

[0026] (1) After stripping the silkworm cocoon shells into pieces, degumming 3 times with 3% sodium carbonate solution, each time boiling in a water bath for 30min, the bath ratio was kept at 1:50; after degumming, fully cleaned with distilled water, put Dry in a vacuum oven at a temperature of 75°C, then dissolve the dried silk protein in a NaOH solution with a mass fraction of 1.5%, and prepare a silk protein solution with a protein content of 13%;

[0027] (2) The wood raw material of the tree is processed by peeling-knotting-slicing, and then cooking-before bleaching and selection-bleaching-post-bleaching and selection-pulp making-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com