Processing method for keeping color of color silks

A processing method, silk technology, applied in silk fiber production, degumming, textile and paper making, etc., can solve the problem of losing the characteristics of colored silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 0

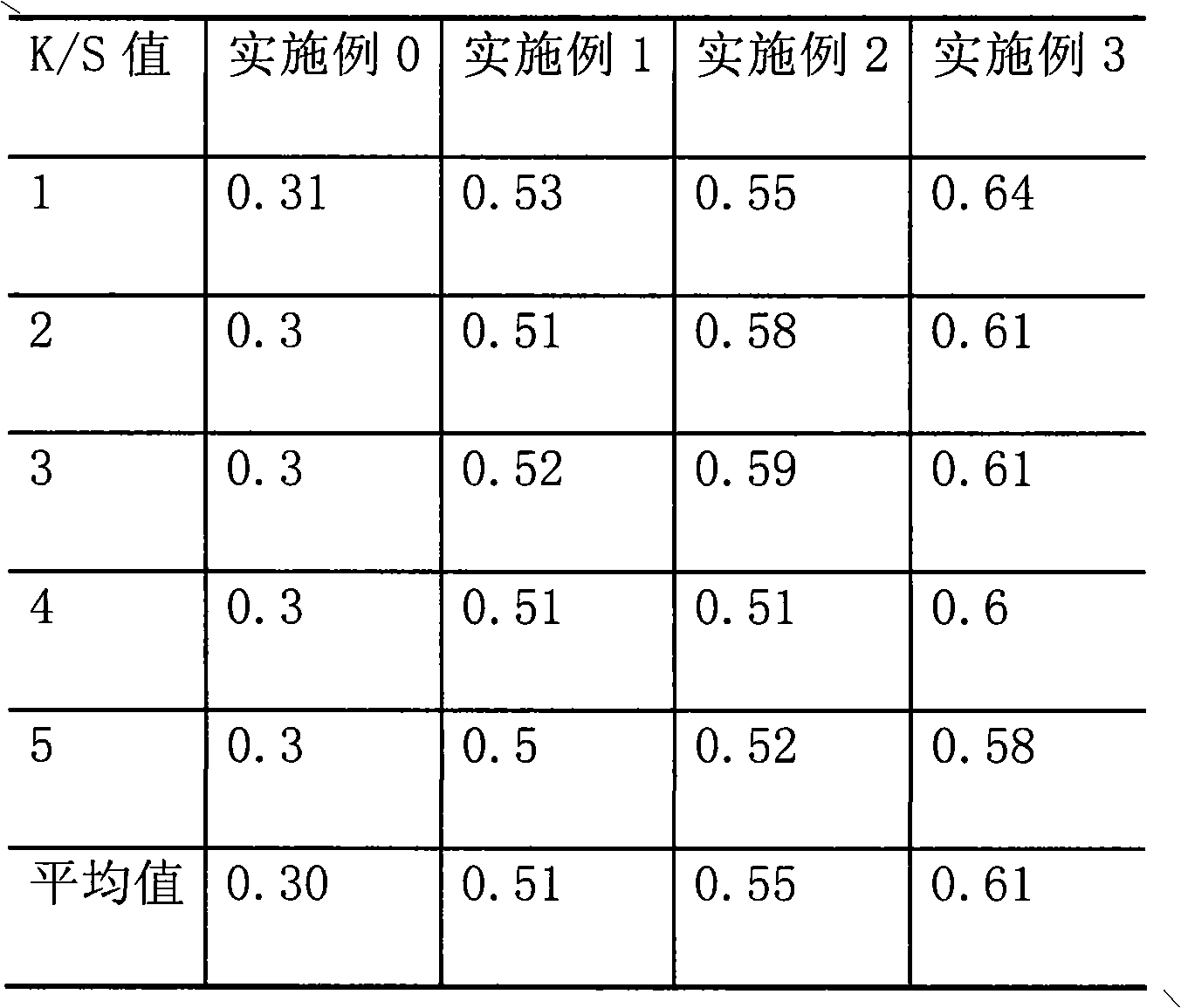

[0031] Embodiment 0: (this example adopts traditional enzyme degumming method to process silk)

[0032] Weigh 2g of the long spit after the above step (1) and step (2) for enzyme degumming treatment, the specific operation is: soak it in 90°C hot water for 30min to make it fully swell, and then put it in 90°C Refining in alkaline solution at ℃ for 30min, the alkaline solution contains Na 2 CO 3 1.5g / L and Pingpingjiao 1g / L, the bath ratio of long spit and alkali solution is 1:50, after scouring is completed, put it in 45°C enzyme solution for scouring for 60min after cooling, the enzyme solution contains 1g of 2709 alkaline protease / L and Pingping plus O 1g / L, the bath ratio of long spit and enzyme solution is 1:50, after scouring, wash with hot water first, and then wash with cold water until neutral, then dry and weigh.

Embodiment 1

[0033] Embodiment 1: (this example has adopted the inventive method to process silk)

[0034] Soak 2g of long spit after the above step (1) and step (2) in 90°C water for 80 minutes, then place the long spit in a steamer for 30 minutes, the steaming temperature is 102°C, and the steaming humidity It was 98%, and degumming was carried out according to the enzyme degumming process of embodiment 0 after steaming.

Embodiment 2

[0035] Embodiment 2: (this example has adopted the inventive method to process silk)

[0036] Put 2g of the long spit treated in the above steps (1) and (2) in an aqueous solution of thiourea with a concentration of 5mol / L and immerse it at a temperature of 95°C for 70min, and then place the long spit in a steamer to steam After 60 minutes, the steaming temperature was 150° C., and the steaming humidity was 85%. After steaming, degumming was carried out according to the enzyme degumming process in Example 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com