Silk fabric degumming method and apparatus thereof

A degumming method and a degumming device technology, applied in the field of silk degumming, can solve the problem of high cost of protease, achieve the effect of improving degumming efficiency and shortening degumming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Test materials and methods:

[0035] Test material: mulberry silk fabric, weight 71g / m 2 . Alkaline protease (activity 100,000 μ / g, produced by Wuxi Xuemei Enzyme Technology Co., Ltd.).

[0036] Buffer solution preparation: prepare with 0.025M sodium carbonate / sodium bicarbonate buffer solution when the pH is 6-8, and prepare with 0.017M potassium dihydrogen phosphate / disodium hydrogen phosphate buffer solution when the pH is 10-11, and the pH value is 9. Prepare with 0.05mol / L borax solution and 0.2mol / L boric acid solution.

[0037] Degumming rate measurement: Dry the sample before and after degumming at 140-145°C for 90 minutes, put it in a glass desiccator, and balance it at room temperature for 30 minutes. The weight obtained is the dry weight before and after degumming until the constant weight. The degumming rate of the sample was calculated by the following formula. Sample degumming rate (%) = [(dry weight before degumming-dry weight after degumming) / dr...

Embodiment 2

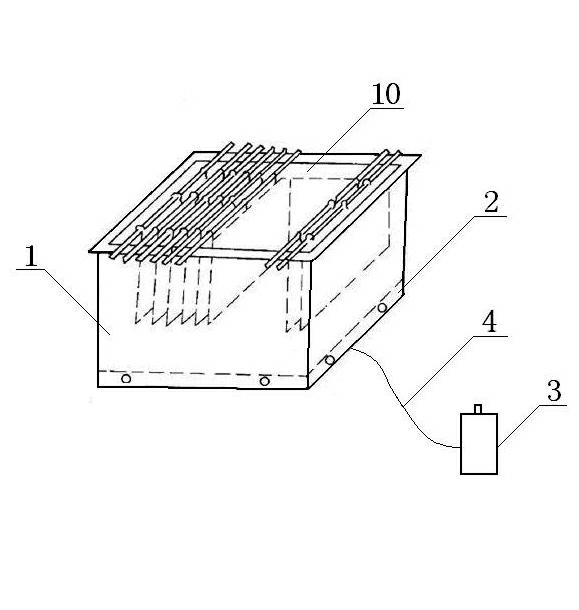

[0060] Such as figure 1 As shown, the present invention also provides a kind of improved silk fabric degumming device, comprises tank body 1, and the top of tank body 1 is provided with opening 10, and the bottom or side of tank body 1 is installed ultrasonic vibrating plate 2, and the size of ultrasonic vibrating plate 2 and The power can be adapted according to the size of the tank body 1, and the ultrasonic vibrating plate 2 can be assembled from a single vibrating plate or from multiple vibrating plates. The ultrasonic generator 3 is installed outside the tank body 1 , and the ultrasonic generator 3 is connected with the ultrasonic vibrating plate 2 through a high frequency line 4 . The frequency range of the ultrasonic vibrating plate 2 is 30-80KHz, and a single-frequency, double-frequency or triple-frequency periodic switching type can be selected. The ultrasonic power can be adjusted by numerical control, and the adjustment range is 10-100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com