Tussah cocoon shell bio-enzyme degumming method and device

A degumming method and a technology of a degumming device, which are applied in degumming and other directions, can solve the problems of uneven degumming, low production efficiency, waste of resources, etc., and achieve the effects of mild working conditions, high product production rate, and increased production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A biological enzyme degumming method for tussah silkworm cocoon shells, said tussah silkworm cocoon shell biological enzyme degumming method consists of the following process steps:

[0024] 1) Add 1000kg of clean water to the degumming tank;

[0025] 2) Heat the water in the degumming tank to 45-50°C;

[0026] 3) Put soda ash into the degumming tank, and stir evenly, so that the pH value of the water in the cocoon cooking tank reaches 9.0;

[0027] 4) Put 0.8 kg of 2709 alkaline protease into the degumming tank to obtain the degumming solution;

[0028] 5) Put 40kg of cocoon shells into the degumming tank, immerse the cocoon shells in the degumming solution, and keep stirring, keep the temperature of the degumming solution at 45-50°C, soak for 4 hours;

[0029] 6) When the residual glue rate of silk is less than or equal to 3%, fish out the silk and the degumming is over.

Embodiment 2

[0031] A biological enzyme degumming method for tussah silkworm cocoon shells, said tussah silkworm cocoon shell biological enzyme degumming method consists of the following process steps:

[0032] 1) Add 1000kg of clean water to the degumming tank;

[0033] 2) Heat the water in the degumming tank to 45-50°C;

[0034] 3) Put soda ash into the degumming tank, and stir evenly, so that the pH value of the water in the cocoon cooking tank reaches 9.0;

[0035] 4) Put 1.6 kg of 2709 alkaline protease into the degumming tank to obtain the degumming solution;

[0036] 5) Put 40kg of cocoon shells into the degumming tank, immerse the cocoon shells in the degumming solution, and keep stirring, keep the temperature of the degumming solution at 45-50°C, soak for 4 hours;

[0037] 6) When the residual glue rate of silk is less than or equal to 3%, fish out the silk and the degumming is over.

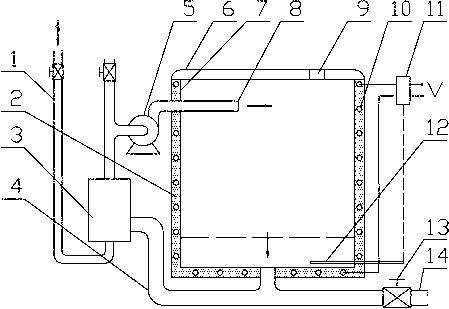

[0038] A biological enzyme degumming device for tussah cocoon shells, comprising a tank cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com