Sulfonic quantum dot/silk fibroin composite nanofiber membrane and preparation method and application thereof

A technology for composite nanofiber and silk fibroin, applied in the field of sulfonic acid quantum dot/silk fibroin composite nanofiber membrane and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

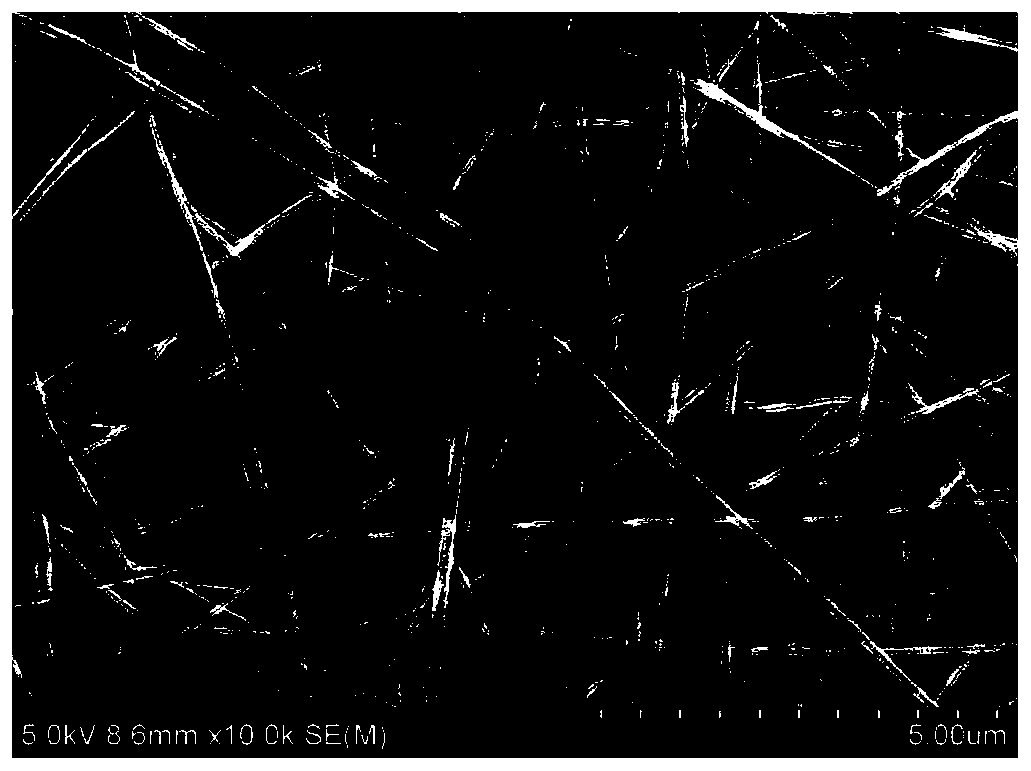

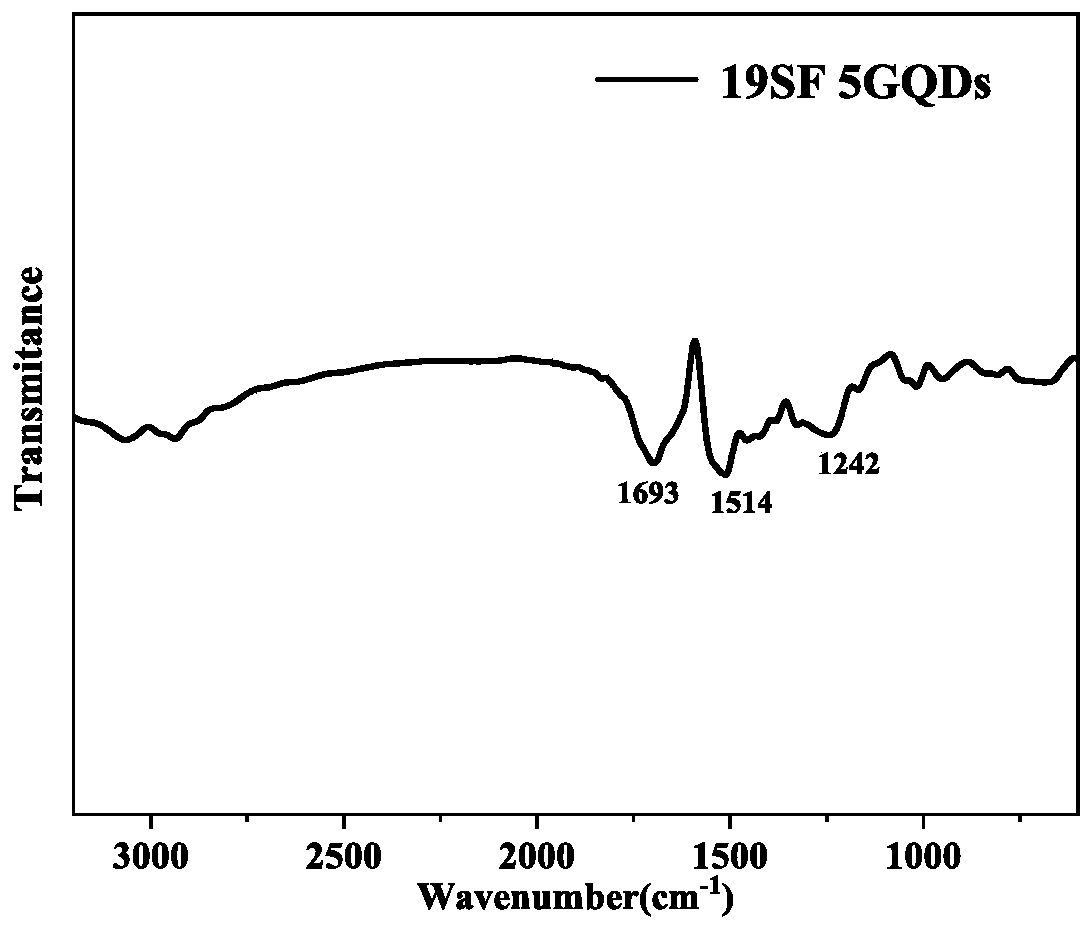

[0051] The present embodiment is the preparation method of a preferred sulfonic acid-based quantum dots / silk fibroin composite nanofiber membrane, which comprises the following steps: 0.5% sodium carbonate (sodium carbonate ( Na 2 CO 3 ) aqueous solution, boiled for 30 minutes, picked up, rinsed with a large amount of deionized water, repeated the above steps three times to carry out degumming treatment, air-dried the silk at room temperature, loosened and packaged for later use. Take 2g of degummed silk and dissolve it in 9mol / L lithium bromide (LiBr) aqueous solution at 40°C for 2 hours, place the resulting solution in a constant temperature laboratory for 10 hours, inject it into a dialysis bag with a molecular weight cut-off of 7000, and dialyze it with deionized water. Stir continuously at low temperature, change the deionized water every 2 hours, centrifuge the obtained solution at a speed of 10000r / min for 15min to remove impurities after 3 days, and vacuum freeze-dry ...

Embodiment 2

[0053] The present embodiment is the preparation method of a preferred sulfonic acid-based quantum dot / silk fibroin composite nanofiber membrane, which comprises the following steps: putting 20 g of shredded cocoons into 1000 ml of boiling mass concentration of 0.7% sodium carbonate ( Na 2 CO 3 ) aqueous solution, boiled for 20 minutes, picked up, rinsed with a large amount of deionized water, repeated the above steps three times to carry out degumming treatment, air-dried the silk at room temperature, loosened and packaged for later use. Take 2g of degummed silk and dissolve it in 6mol / L lithium bromide (LiBr) aqueous solution at 40°C for 3 hours, place the resulting solution in a constant temperature laboratory for 12 hours, inject it into a dialysis bag with a molecular weight cut-off of 8000, and dialyze it with deionized water. Stir continuously at low temperature, change the deionized water every 1.5 hours, centrifuge the obtained solution at a speed of 12000r / min for 1...

Embodiment 3

[0055] This embodiment is the cytotoxicity experiment of the sulfonic acid-based quantum dots / silk fibroin composite nanofiber membrane prepared in Example 1:

[0056] The biocompatibility of the fiber membrane prepared in Example 1 was evaluated according to the ISO10993-5 standard test (indirect contact) method. After the composite nanofibrous membrane was soaked in 75% and sterilized by ultraviolet light, it was immersed in a 24-well polystyrene plate containing complete medium at 37°C (6 cm 2 ·mL -1 ) for 24 hours. Mouse fibroblasts (L929) were used at 5×10 per well 3 The density was seeded in a 96-well plate in 5% CO 2 After 24 hours of incubation in a 37°C incubator, replace the medium in the 96-well plate with 100 μL of the extraction medium in the 24-well plate and continue to cultivate for 24 hours, then add 10 μL of CCK8 reagent to each well, and continue to culture in the incubator After 4 hours, the absorbance at 450 nm was measured with a microplate reader. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com