Biological degumming cocoon reelability method for China oak silkworm

A biological degumming and silkworm cocoon technology, which is applied in the field of biological degumming and unwinding of tussah silkworm cocoons, can solve the problems of high broken ends, unsatisfactory results, short filaments, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

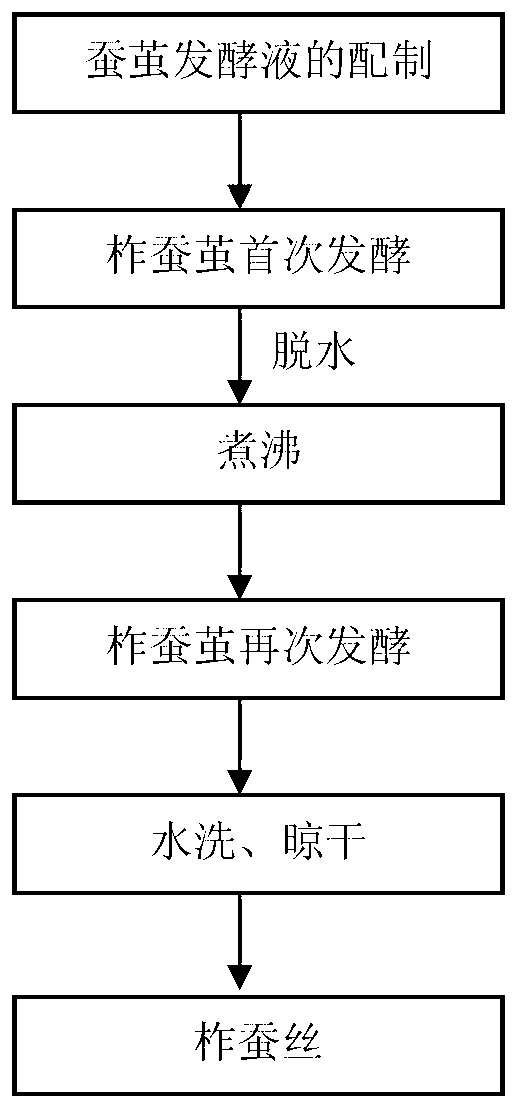

Image

Examples

Embodiment 1

[0022] Example 1 is used for the composite bacterial agent of tussah silkworm cocoon biological degumming and relaxing

[0023] Preparation of compound bacterial agent:

[0024] It is prepared by mixing the following components in equal parts: EM bacterium freeze-dried powder, Bacillus megaterium powder, Bacillus subtilis powder and Bacillus licheniformis powder. Among them, the freeze-dried powder of EM bacteria was purchased from Jiangsu Lvke Biotechnology Co., Ltd., and its main components are photosynthetic bacteria, Bacillus, lactic acid bacteria, nitrifying bacteria, actinomycetes, natto bacteria, etc., and the number of effective viable bacteria was ≥5×10 9 CFU / g; Bacillus megaterium powder was purchased from Jiangsu Lvke Biotechnology Co., Ltd., and the live bacteria content was ≥10×10 9 CFU / g; Bacillus subtilis powder and Bacillus licheniformis powder were purchased from Hubei Qiming Biological Engineering Co., Ltd., and the effective number of viable bacteria was 30...

Embodiment 2

[0025] The biological degumming and relaxing process of the tussah cocoon of embodiment 2

[0026] The operation steps are as follows:

[0027] (1) Preparation of silkworm cocoon fermentation broth: Dissolve 75g of the composite microbial agent prepared in Example 1 in 100kg of water, add 1kg of brown sugar and 0.25kg of EM ecological probiotic stock solution, and mix well to obtain silkworm cocoon fermentation broth.

[0028] Among them, the EM ecological probiotic stock solution was purchased from Beijing Zhongke Huinong Technology Service Center, and its main components were Saccharomyces cerevisiae and Lactobacillus casei, and the effective number of viable bacteria was ≥2×10 8 CFU / g.

[0029] (2) The first fermentation of tussah cocoons: Soak the tussah cocoons in the above-mentioned cocoon fermentation liquid (it is better to soak all the tussah cocoons in the fermentation liquid), and ferment in a sealed manner at 39°C for 8 days.

[0030] (3) Boiling: After the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com