Ultrasonic-assisted rapeseed oil degumming method

An ultrasonic-assisted, rapeseed oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problem of low degumming efficiency and achieve the effect of improving degumming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

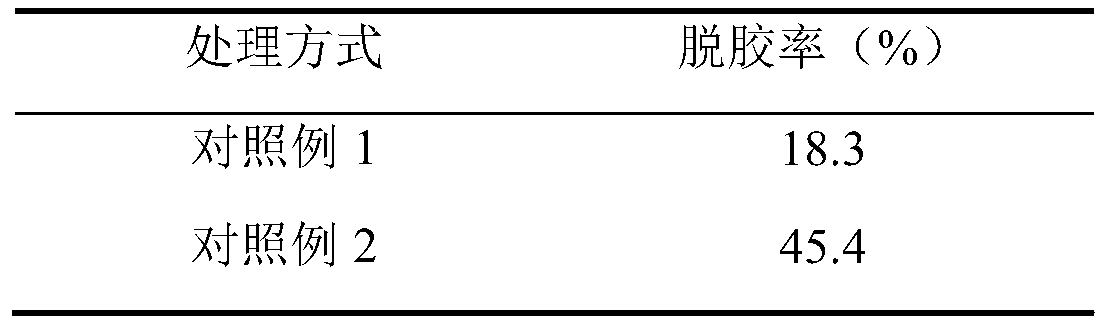

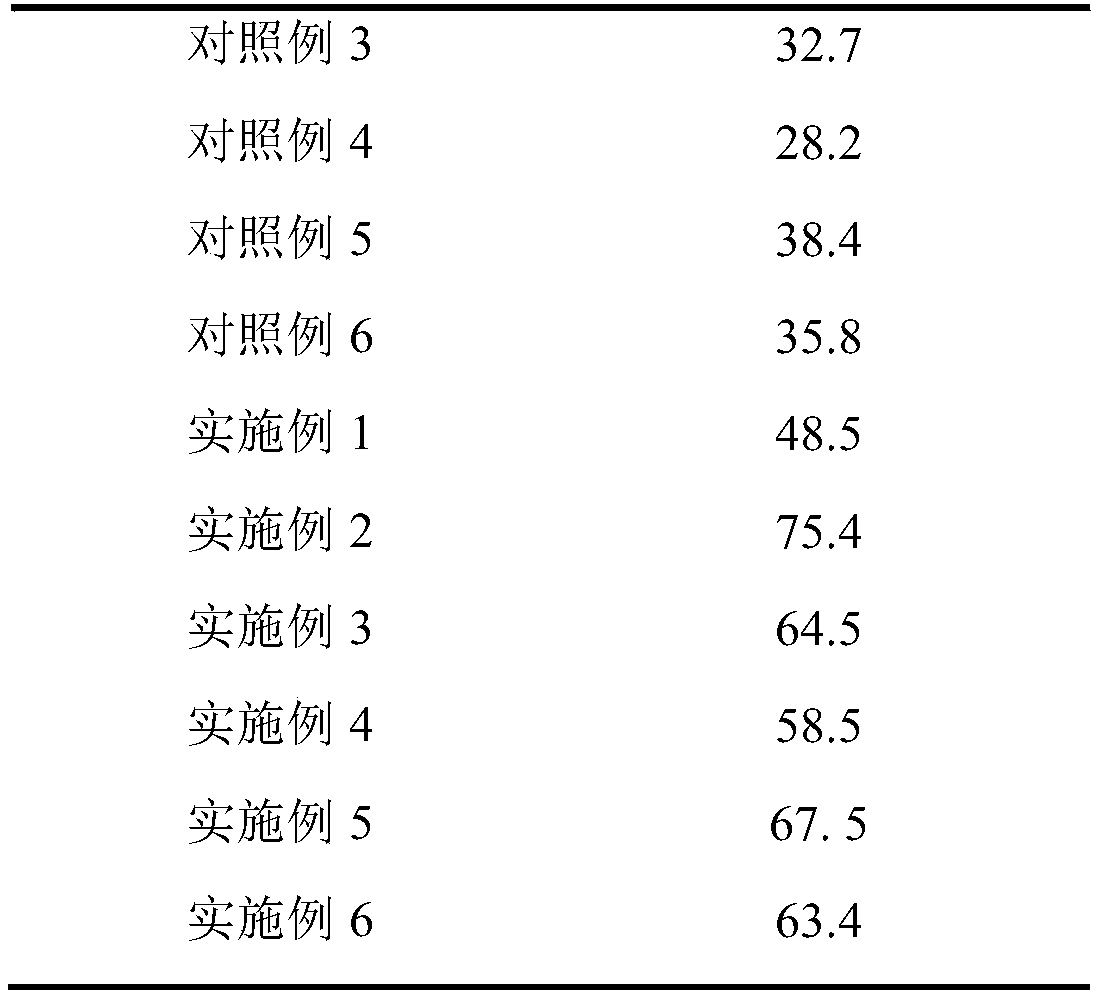

[0024] (1) Weigh 50g rapeseed crude oil in an Erlenmeyer flask, heat to 40°C, weigh citric acid with a mass ratio of 0.05%, and distilled water with a mass ratio of 1.5%, mix and dissolve the citric acid and distilled water , heating the citric acid solution to the same temperature as the crude oil, adding it to the crude oil, and stirring to hydrate it for 10 min; (2) ultrasonic treatment with a frequency of 40 kHz and a power of 150 W for 10 min, leaving it at room temperature for 5 min, and then centrifuging (4800r / min, 20min); (3) Rotate the upper oil layer at 0.09Mpa and 70°C to remove water; (4) Take 10mL of the oil phase to measure the phosphorus content according to GB / T5537-2008 "Determination of Phospholipid Content in Grain and Oil Inspection", and calculate Degumming rate. See Table 1.

Embodiment 2

[0026] (1) Weigh 50g rapeseed crude oil in an Erlenmeyer flask, heat to 80°C, weigh citric acid with a mass ratio of 0.35%, and distilled water with a mass ratio of 4.0%, mix and dissolve the citric acid and distilled water , heating the citric acid solution to the same temperature as the crude oil, adding it to the crude oil, and stirring to hydrate it for 60 min; (2) using ultrasonic treatment with a frequency of 40 kHz and a power of 150 W for 30 min, leaving it at room temperature for 5 min, and centrifuging (4800r / min, 20min); (3) Rotate the upper oil layer at 0.09Mpa and 70°C to remove water; (4) Take 10mL of the oil phase to measure the phosphorus content according to GB / T5537-2008 "Determination of Phospholipid Content in Grain and Oil Inspection", and calculate Degumming rate. See Table 1.

Embodiment 3

[0028] (1) Weigh 50g rapeseed crude oil in an Erlenmeyer flask, heat to 60°C, weigh citric acid with a mass ratio of 0.2%, and distilled water with a mass ratio of 2.5%, mix and dissolve the citric acid and distilled water , heating the citric acid solution to the same temperature as the crude oil, adding it to the crude oil, and stirring to hydrate it for 30 minutes; (2) ultrasonic treatment with a frequency of 40 kHz and a power of 150 W for 20 minutes, leaving it at room temperature for 5 minutes and then centrifuging (4800r / min, 20min); (3) Rotate the upper oil layer at 0.09Mpa and 70°C to remove water; (4) Take 10mL of the oil phase to measure the phosphorus content according to GB / T5537-2008 "Determination of Phospholipid Content in Grain and Oil Inspection", and calculate Degumming rate. See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com