Method for preparing laccase by using mucor circinelloides DK1 strain

A technology of Mucor circinigii and bacterial strains, which is applied in the field of preparing laccase by Mucor circinzia DK1 strain, can solve the problems of high energy consumption in the chemical degumming process, waste water cannot be recycled, and large equipment loss, etc., and achieves good application prospects and degumming High efficiency and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

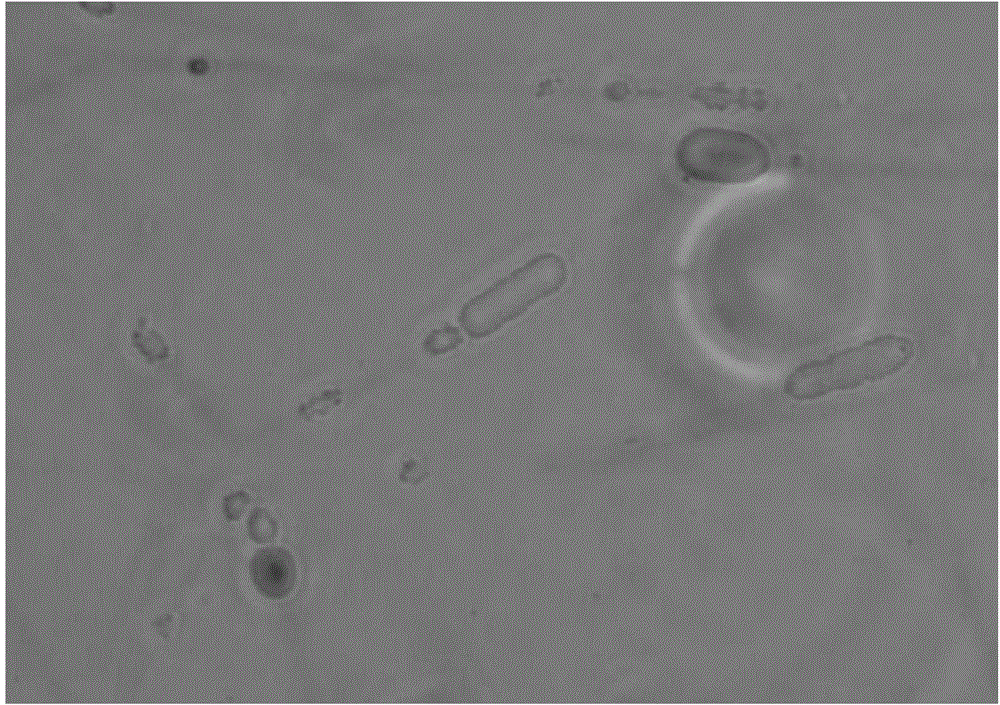

Image

Examples

Embodiment 1

[0026] The method for preparing laccase by Mucor circiniferus DK1 strain:

[0027] (1) Mycelia suspension: Mucor circiniferatum DK1 strain was transferred from PDA slant medium into a 300mL Erlenmeyer flask containing 50mL of basic liquid medium, and cultured in a shaker at 180rpm at a constant temperature of 30°C for 3 days, then fermented The liquid was filtered through sterile gauze, the mycelium was washed with sterile water and dispersed in a Waring high-speed crushing cup for 15 seconds, collected in sterile water (equal to the volume of the fermentation broth) to make a suspension of mycelia, and collected at 40 Store at ℃ for later use.

[0028] Basic liquid medium: 200g potato, 20g glucose, 1000mL distilled water, natural pH.

[0029] (2) Enzyme production in shake flasks: add 1% (w / v) natural substrate) and different concentrations of CuSO in the base liquid medium 4 ·5H 2 O (0-4mM) is the enzyme production medium. Put 80mL of enzyme-producing medium into a 300mL...

Embodiment 2

[0033] The degumming process of flax, jute, kenaf or bamboo fiber prepared by the laccase crude enzyme solution prepared by Mucor circini DK1 is as follows:

[0034] Put 5g of flax, jute, kenaf or bamboo fiber raw stems in a 250ml conical flask, and use flax, jute, kenaf or bamboo fiber raw stems and laccase crude enzyme solution in a mass ratio of 1:20 to pack in conical flasks 100ml liquid, degumming at 40°C, 200rpm shaker for 1 day, 2 days and 4 days respectively; when the degumming time is up, remove the degumming solution, boil in a boiling water bath for 5min, rinse with tap water several times, and Remove bacteria from linen and stop degumming.

[0035] Through the observation of flax, jute, kenaf or bamboo fiber degumming, it was found that after 1 day, the degumming of flax, jute, kenaf or bamboo fiber was obviously dispersed, and the color of the fermentation liquid became dark and turbid; , kenaf or bamboo fibers are dispersed into fibers, and the fermented liquid ...

Embodiment 3

[0037] The process of preparing laccase enzyme solution for degumming in flax, jute or kenaf yarn by Mucor circinzia DK1 is as follows:

[0038]Put 5g of flax, jute or kenaf yarn into a 250ml conical flask, and divide flax, jute or kenaf yarn and laccase enzyme solution into the conical flask according to the mass ratio of 1:20, and the liquid volume is 100ml , degumming at 40°C, 200rpm shaker for 1 day, 2 days and 4 days respectively; when the degumming time is up, remove the degumming solution, boil in a boiling water bath for 5min, and rinse with tap water several times to remove flax, jute or kenaf Bacteria on yarn, stop degumming.

[0039] Through the observation of flax, jute or kenaf yarn degumming, it was found that the flax fiber was obviously dispersed after 1 day, and the color of the fermentation liquid became turbid; Days later, the flax degumming rate reached over 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com