High-temperature vapor-water mixed jet cleaning system and method

A high-temperature water vapor and cleaning system technology, which is applied in cleaning methods and tools, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of underlying silicon loss, damage to the sensitive structure of the wafer surface, etc., and achieve deglue efficiency Enhanced, loss-minimized, residue-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

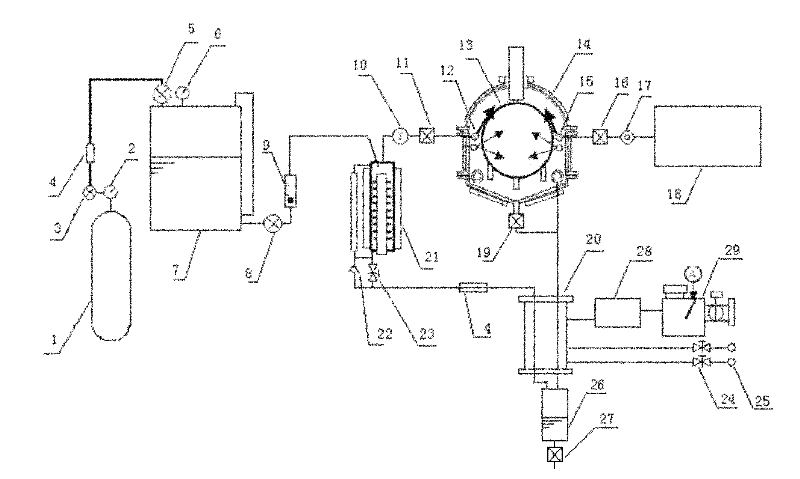

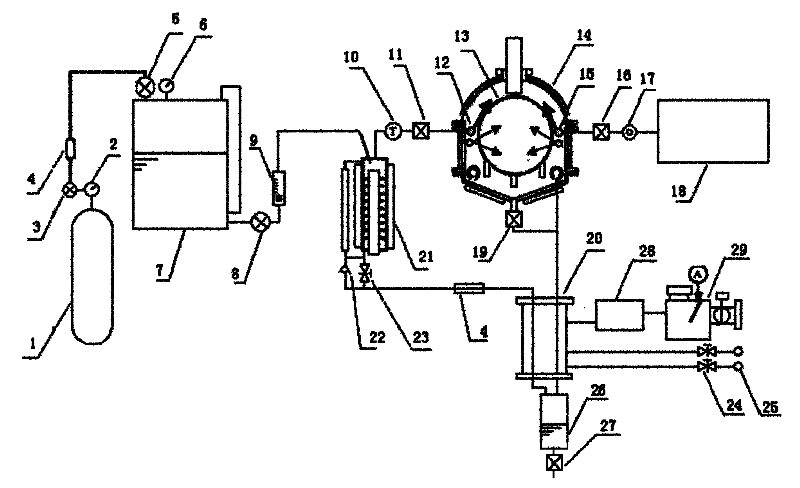

[0028] The process of the cleaning method is as follows: put the sample into the tray 13 and fix it; heat the heat exchanger 21 by setting the temperature value of the constant temperature control and display device 10, and when the temperature reaches the required temperature, adjust the pressure reducing valve 3 and open the valve 5 and valve 8, adjust the flow meter 9, at this time N 2 Through the valve 5 and the valve 8, and through the flow meter 9 to control the flow rate, the deionized water is sent into the heat exchanger 21, and the deionized water absorbs heat in the heat exchanger 21 to form a high-temperature steam of 200 ° C, and then passes through the nozzle 12 Spray to the sample surface fixed on the tray 13 in the cleaning chamber 14; adjust the mass flow controller 17, open the valve 16, and the ozone produced by the ozone generator 18 is sprayed to the sample surface fixed on the tray 13 through the nozzle 15; The sample surface fixed on the tray 13 in the c...

Embodiment 2

[0030] The process of the cleaning method is as follows: put the sample into the tray 13 and fix it; heat the heat exchanger 21 by setting the temperature value of the constant temperature control and display device 10, and when the temperature reaches the required temperature, adjust the pressure reducing valve 3 and open the valve 5 and valve 8, adjust the flow meter 9, at this time N 2 Through the valve 5 and the valve 8, and through the flow meter 9 to control the flow, the deionized water is sent into the heat exchanger 21, and the deionized water absorbs heat in the heat exchanger 21 to form a high-temperature steam of 300 ° C, and then passes through the nozzle 12 Spray to the sample surface fixed on the tray 13 in the cleaning chamber 14; adjust the mass flow controller 17, open the valve 16, and the ozone produced by the ozone generator 18 is sprayed to the sample surface fixed on the tray 13 through the nozzle 15; The sample surface fixed on the tray 13 in the chambe...

Embodiment 3

[0032] The process of the cleaning method is as follows: put the sample into the tray 13 and fix it; heat the heat exchanger 21 by setting the temperature value of the constant temperature control and display device 10, and when the temperature reaches the required temperature, adjust the pressure reducing valve 3 and open the valve 5 and valve 8, adjust the flow meter 9, at this time N 2 Through the valve 5 and the valve 8, and through the flow meter 9 to control the flow, the deionized water is sent into the heat exchanger 21, and the deionized water absorbs heat in the heat exchanger 21 to form a high-temperature steam of 400 ° C, and then passes through the nozzle 12 Spray to the sample surface fixed on the tray 13 in the cleaning chamber 14; adjust the mass flow controller 17, open the valve 16, and the ozone produced by the ozone generator 18 is sprayed to the sample surface fixed on the tray 13 through the nozzle 15; The sample surface fixed on the tray 13 in the chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com