Bamboo fiber degumming process through continuous scouring and process device

A bamboo fiber and scouring technology, which is applied in fiber treatment, fiber mechanical separation, fiber chemical post-treatment, etc., can solve the problems of bamboo filaments not being continuous and integrally conveyed, and achieve the effect of improving degumming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

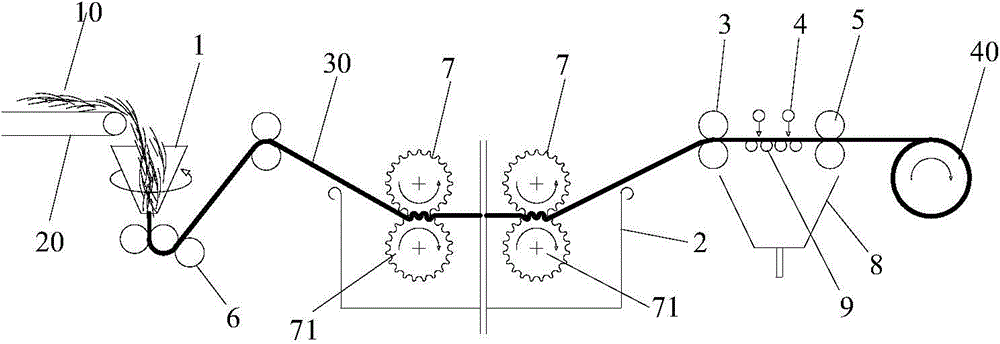

[0037] Select the bamboo silk 10 of 0.3~0.5mm diameter to send into twisting hopper 1 through conveyer belt 20 and twist into rope-like bamboo fiber 30, take out by transition roller 6 and send into scouring pool 2; Carry out scouring and the rubbing of kneading roller 7 simultaneously in 2; Output by the first output roller 3 again, and after powerful water spray device 4 cleans, then by the second output roller 5, roll dry, become bamboo fiber roll 40 at last.

[0038] Main process settings:

[0039] Rotating speed of twisting bucket 1: match with the conveying speed of bamboo silk, so that the twist is 5-15 twists / 50cm;

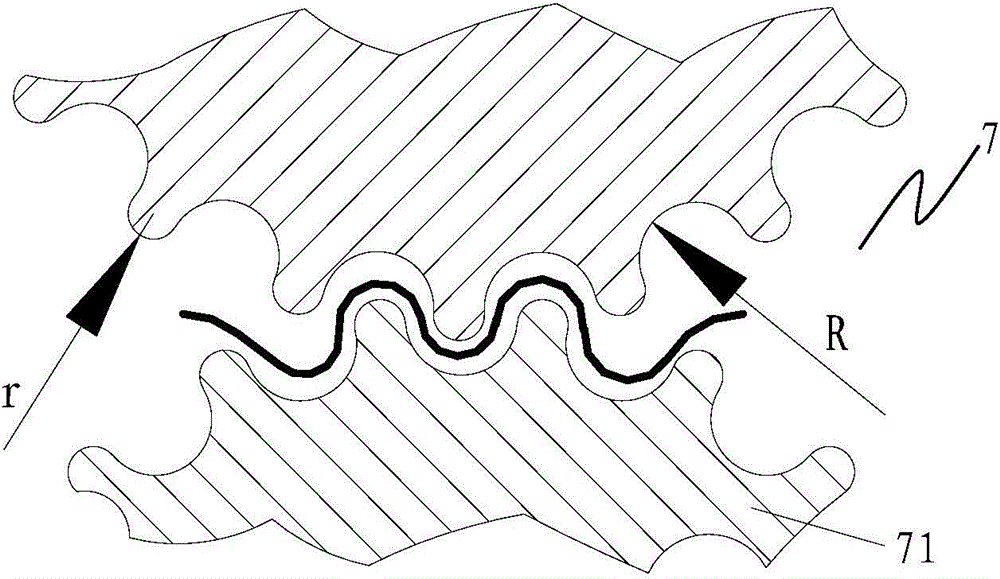

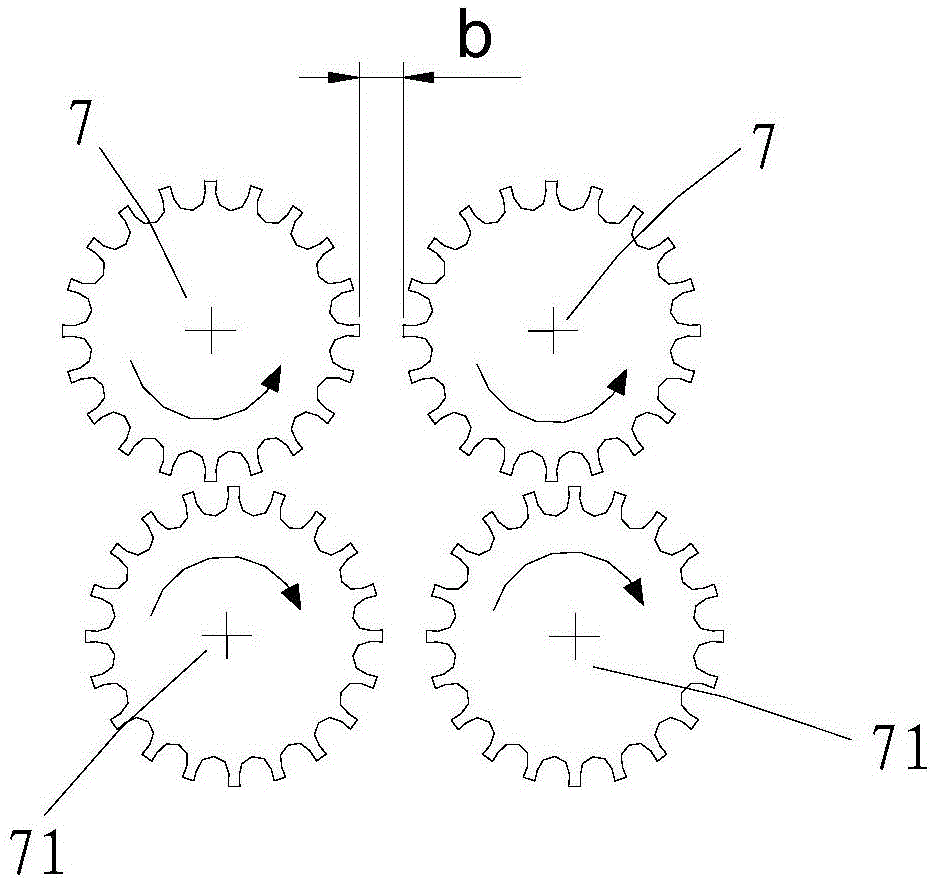

[0040] Kneading roller 7: set 40 pairs;

[0041] The gap b between adjacent kneading rollers: 25cm;

[0042] Bamboo silk 10 conveying speed: 0.1m ~ 0.15m / 10 minutes;

[0043] Powerful water spray device 4 water pressure: 3 ~ 6Kg / cm 2 .

Embodiment 2

[0045]Select the bamboo silk 10 of 0.1~0.3mm diameter to send into twisting hopper 1 through conveyer belt 20 and twist into rope-like bamboo fiber 30, take out by transition roller 6 and send into scouring pool 2; Carry out scouring and the rubbing of kneading roller 7 simultaneously in 2; Output by the first output roller 3 again, and after powerful water spray device 4 cleans, then by the second output roller 5, roll dry, become bamboo fiber roll 40 at last.

[0046] Main process settings:

[0047] Rotating speed of twisting bucket 1: match with the conveying speed of bamboo filament 10, so that the twist is 10-30 twists / 50cm;

[0048] Kneading roller 7: set 30 pairs;

[0049] The gap b between adjacent kneading rollers: 10cm;

[0050] Bamboo silk 10 conveying speed: 0.1m ~ 0.15m / 10 minutes;

[0051] Powerful water spray device 4 Water pressure: 0~3Kg / cm 2 .

[0052] The present invention uses the bamboo fiber bundle (0.1-0.5mm in diameter) as the raw material after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com