Silicon wafer degumming device

A silicon wafer and deionized water technology, applied in the processing of photosensitive materials, can solve the problems of underlying silicon loss, damage to the sensitive structure of the wafer surface, etc., and achieve minimum loss, low mean square error roughness, and high deglue efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

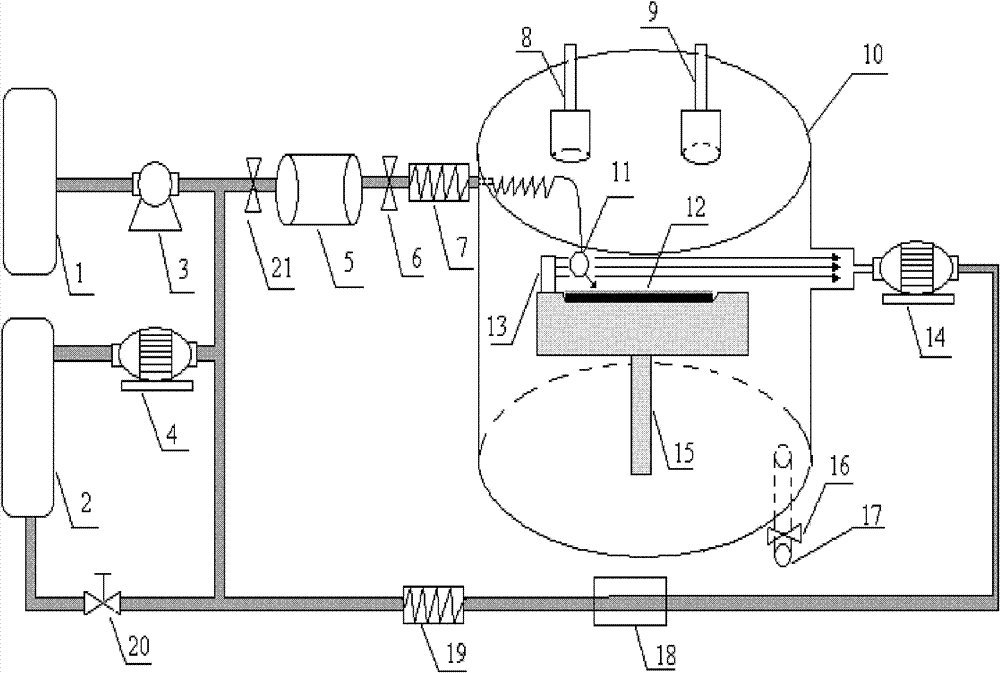

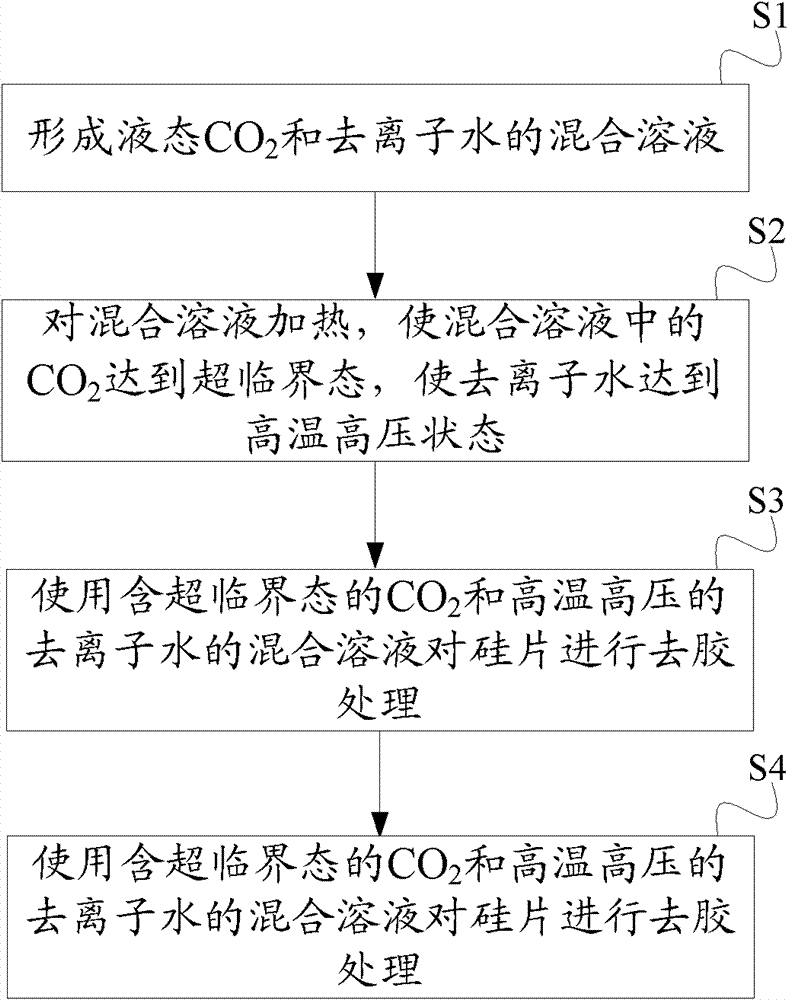

[0014] Such as figure 1 As shown, the silicon wafer degumming device provided by the embodiment of the present invention includes a deionized water storage tank 1, a CO 2 Gas storage tank 2, for deionized water and CO 2 5. Heating the mixed solution to make the CO in the mixed solution 2 A heat exchanger 7 that reaches a supercritical state and makes deionized water reach high temperature and high pressure, a reaction chamber 10 for removing glue from silicon wafers 12, CO 2 Recovery device. The reaction chamber 10 is provided with a rotatable tray 15 for placing a silicon wafer 12 coated with photoresist, a CO for stripping the stripped photoresist tape from the surface of the silicon wafer 12. 2 Source 13 (which may be a cylinder), temperature sensor 8 and pressure sensor 9 . CO 2 The source 13 is used to lift the stripped photoresist tape away from the surface of the sample sheet and be taken out of the reaction chamber 10 at the same time. The tray 15 containing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com