Biological degumming device and method for cotton stalk skin

A technology of biological degumming and cotton stalk skin, which is applied in the field of biological degumming device of cotton stalk skin, can solve the problems of cumbersome process, affecting processing, low fiber strength, etc., and achieve the effect of increasing specific surface area, reducing difficulty, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

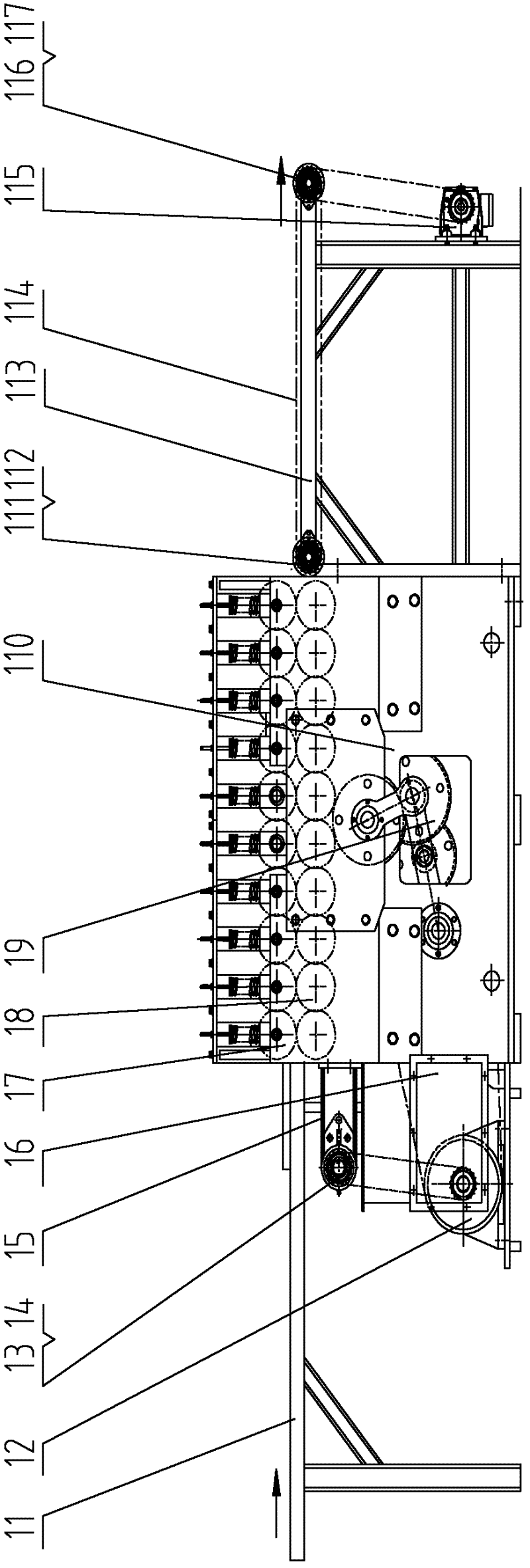

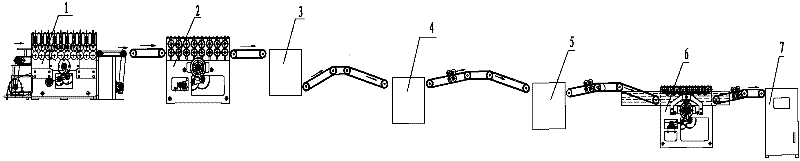

[0117] The cotton stalks purchased from Yuanjiang, Hunan will be used figure 2 The cotton stalk sheath-core separating device shown in the figure separates the sheath-core to obtain the cotton stalk sheath;

[0118] Re-drying the cotton stalk skin so that the moisture content of the cotton stalk skin is 10%;

[0119] Dehulling and pre-fibrillation of the re-dried cotton stalks;

[0120] Put the peeled and pre-fibered raw cotton stalks into pots, the thickness of the cotton stalks in the pots is 60mm to 120mm; move the pots into the fermentation equipment disclosed in Chinese patent document 200620050490.7, the weight of the raw cotton stalks in the fermentation equipment is 50kg ;

[0121] Dilute Erwinia carotovora soft rot with tap water to a suspension of 107cfu / mL of viable bacteria after expanded culture, and use a bath ratio of 1:10 to ferment the raw cotton in the fermentation equipment when the water temperature is 37°C and the pH is 4.5. Soak the stalks; then adjus...

Embodiment 2

[0125] The cotton stalks purchased from Yuanjiang, Hunan will be used figure 2 The cotton stalk sheath-core separating device shown in the figure separates the sheath-core to obtain the cotton stalk sheath;

[0126] The cotton stalk skin is dried again, so that the moisture content of the cotton stalk skin is 12%;

[0127] Dehulling and pre-fibrillation of the re-dried cotton stalks;

[0128] Put the raw cotton stalk skin after dehulling and pre-fibering into a basin, and the thickness of the cotton stalk skin in the basin is 100mm; move the pot into the fermentation equipment disclosed in Chinese Patent Document 200620050490.7, and the weight of the raw cotton stalk skin in the fermentation equipment is 70kg;

[0129] Erwinia carrot soft rot was expanded and then diluted with tap water to a viable count of 10 7 cfu / mL bacterial suspension, according to the bath ratio of 1:10, soak the raw cotton bark in the fermentation equipment when the water temperature is 37°C and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com