High temperature vapor and water mixed jet cleaning system and method thereof

A high-temperature water vapor and cleaning system technology, applied in cleaning methods and tools, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of damaging the sensitive structure of the wafer surface and the loss of underlying silicon, and minimize the loss , Improved degumming efficiency, no residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

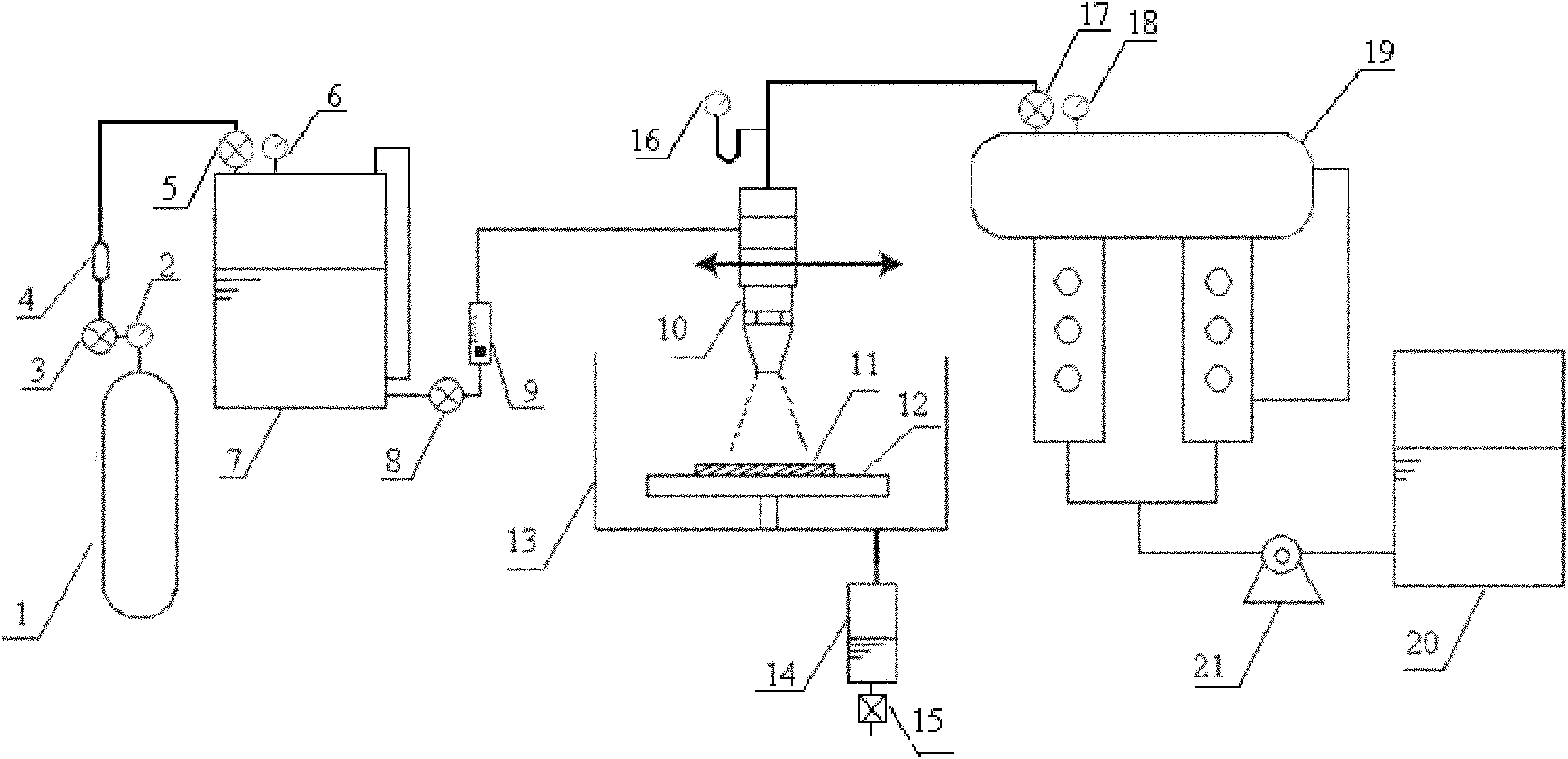

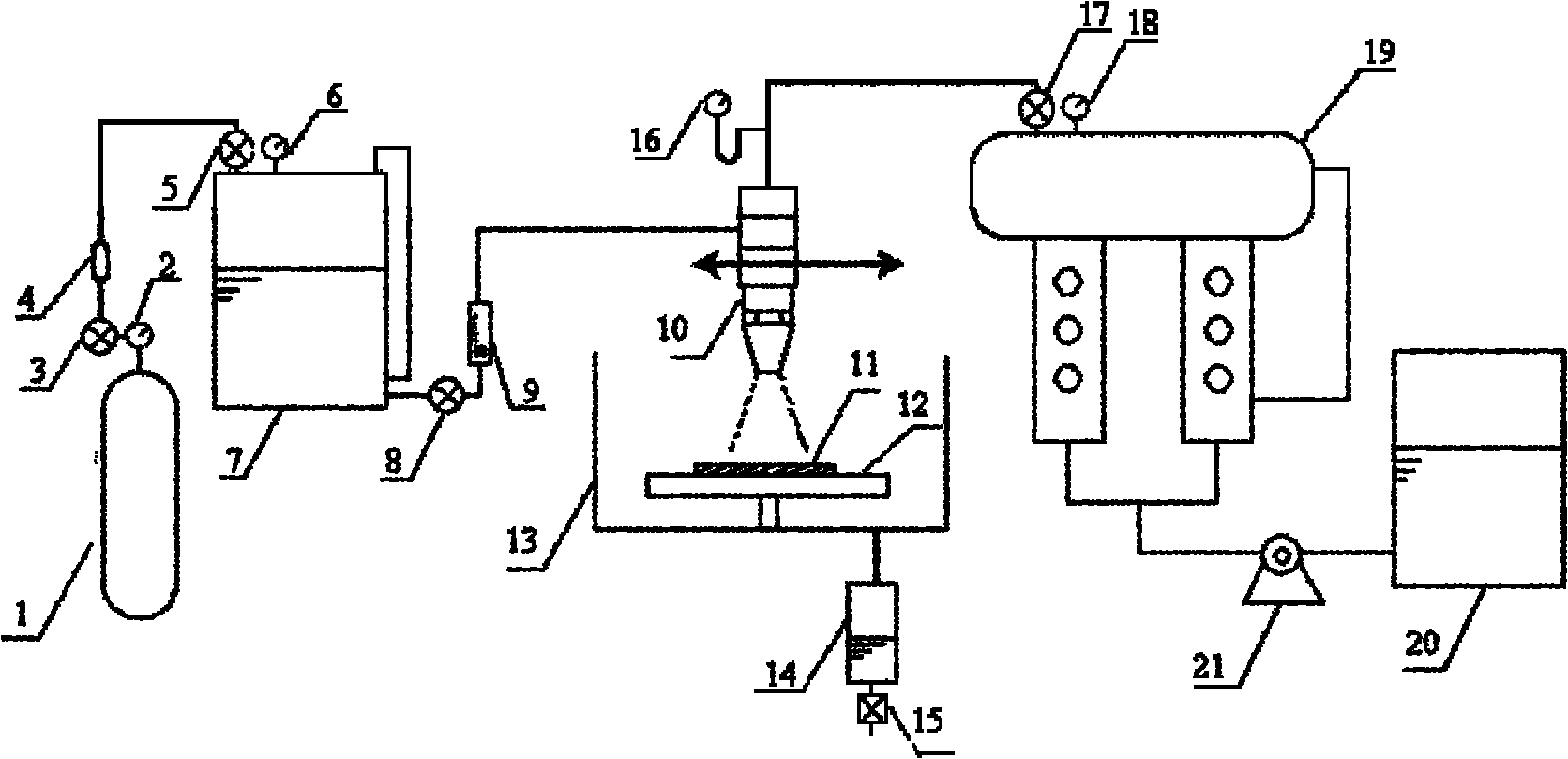

[0025] The process of the method is as follows: put the sample piece 11 into the tray 12 and fix it, the tray 12 can choose whether to rotate according to the needs; heat the heat exchanger 19 by setting the temperature value of the temperature control and display device 18, when the temperature reaches the required temperature (for example 300 ℃), adjust the pressure reducing valve 3, run the booster pump 21, adjust the flow meter 9; at this time N 2 The deionized water will pass through the valve 5, and the flow rate is controlled by the flow meter 9, and the deionized water will flow into the mixing chamber in the injection device 10. The deionized water will absorb heat through the heat exchanger 19 to form high-temperature steam at 100 ° C, and then pass through the valves in turn. 17. The pressure gauge 16 flows into the mixing chamber in the injection device 10; deionized water and high-temperature steam are mixed in the mixing chamber to form a mixed fluid with a ratio ...

Embodiment 2

[0027] The process of the method is as follows: put the sample piece 11 into the tray 12 and fix it, the tray 12 can choose whether to rotate according to the needs; heat the heat exchanger 19 by setting the temperature value of the temperature control and display device 18, when the temperature reaches the required temperature , adjust the pressure reducing valve 3, run the booster pump 21, adjust the flow meter 9; at this time N 2 The deionized water will pass through the valve 5, and the flow rate is controlled by the flow meter 9, and the deionized water will flow into the mixing chamber in the injection device 10. The deionized water will pass through the heat exchanger 19 to absorb heat to form high-temperature steam at 300 ° C, and then pass through the valves in turn. 17. The pressure gauge 16 flows into the mixing chamber in the injection device 10; deionized water and high-temperature water vapor are mixed in the mixing chamber to form a mixed fluid with a ratio of 60...

Embodiment 3

[0029] The process of the method is as follows: put the sample piece 11 into the tray 12 and fix it, the tray 12 can choose whether to rotate according to the needs; heat the heat exchanger 19 by setting the temperature value of the temperature control and display device 18, when the temperature reaches the required temperature , adjust the pressure reducing valve 3, run the booster pump 21, adjust the flow meter 9; at this time N 2 The deionized water will pass through the valve 5, and the flow rate is controlled by the flow meter 9, and the deionized water will flow into the mixing chamber in the injection device 10. The deionized water will pass through the heat exchanger 19 to absorb heat to form high-temperature steam at 500 ° C, and then pass through the valves in turn. 17. The pressure gauge 16 flows into the mixing chamber in the injection device 10; deionized water and high-temperature steam are mixed in the mixing chamber to form a mixed fluid with a ratio of 80%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com