Method for degumming silybum marianum seed oil

A technology of milk thistle seed oil and degumming method, which is applied in the field of degumming of milk thistle seed oil, can solve the problems of high unsaturated fatty acid content, difficulty in oil refining, difficult to grasp the stability of refining process, etc., and achieves low phospholipid content. , High degumming efficiency, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

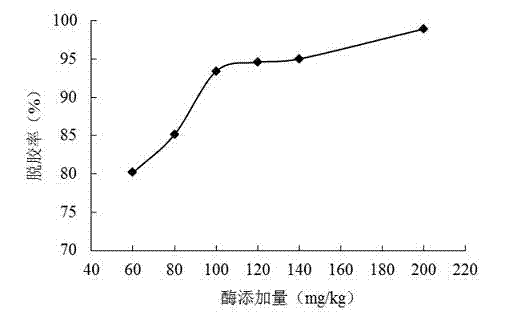

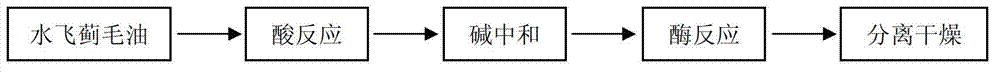

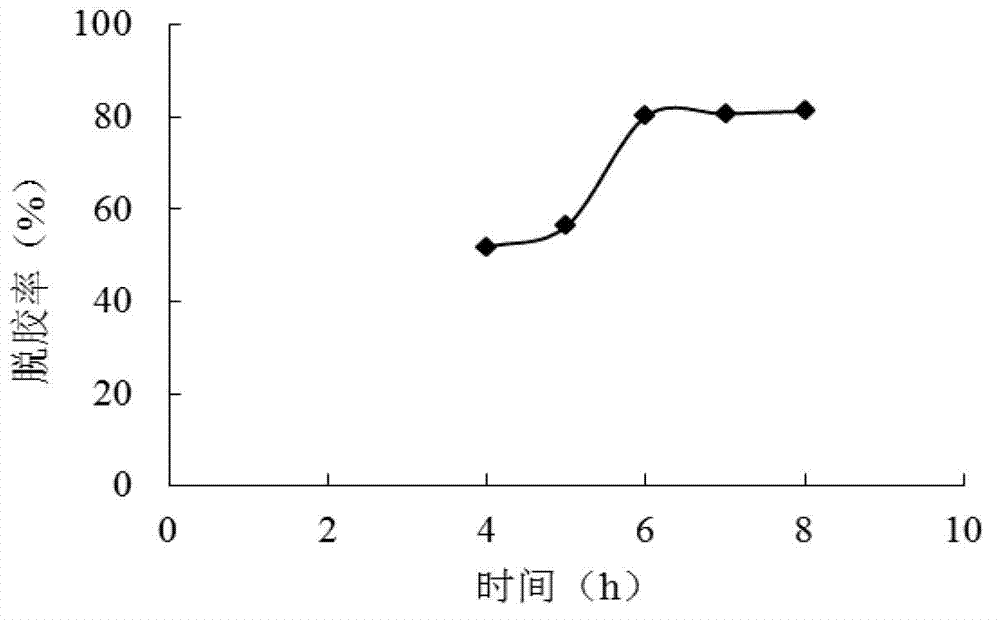

[0021] Optimum test of process data for enzymatic degumming of milk thistle seed oil.

[0022] Experimental plan: through the single factor experiment of the amount of enzyme added and the reaction time of the enzyme, the optimal reaction conditions were explored.

[0023] Materials and methods 1.1 Raw materials and reagents Crude milk thistle oil was pressed, with an initial phospholipid content of 273 mg / kg; Lecitase® Ultra: A1-position phospholipase, produced by microbial fermentation, Novozyme; other reagents: analytically pure. 1.2 Main instruments Electric constant temperature water bath, JB90-D powerful electric mixer, 752 spectrophotometer, etc. 1.3 Analysis of phosphorus content Take an appropriate amount of milk thistle seed oil to analyze the phosphorus content in the oil, referring to the molybdenum blue colorimetric method in GBT 5537-2008. 1.4 Enzymatic degumming step Use a 100mL round bottom flask to accurately weigh 50g of milk thistle crude oil, heat ...

Embodiment 2

[0031] Accurately weigh 50g of milk thistle crude oil in a 100mL round bottom flask, heat the crude oil in a water bath to 70-80°C, add 45% (w / v) citric acid solution at the same temperature according to the dosage ratio of 0.12mL / 100g crude oil , 500r / min mechanical stirring for 20-30min. Then cool to 50-55°C, add 4% (w / v) NaOH solution to adjust the pH to 5-5.3. Then add phospholipase according to the amount of 60mg / kg crude oil, keep it in a water bath for 4h under the condition of mechanical stirring at 500r / min, then let it stand for 3-8h, centrifuge at 10000r / min for 10min, remove the phospholipid, and obtain the degummed milk thistle Seed oil was analyzed for phospholipid content, and the measured phospholipid content was 131.53 mg / kg.

Embodiment 3

[0033]Accurately weigh 50g of milk thistle crude oil in a 100mL round bottom flask, heat the crude oil in a water bath to 70-80°C, add 45% (w / v) citric acid solution at the same temperature according to the dosage ratio of 0.12mL / 100g crude oil , 500r / min mechanical stirring for 20-30min. Then cool to 50-55°C, add 4% (w / v) NaOH solution to adjust the pH to 5-5.3. Then add phospholipase according to the amount of 60mg / kg crude oil, keep it in a water bath for 8h under the condition of mechanical stirring at 500r / min, then let it stand for 3-8h, centrifuge at 10000r / min for 10min, remove the phospholipid, and obtain the degummed milk thistle Seed oil was analyzed for phospholipid content, and the measured phospholipid content was 51.16 mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com