Method for refining camellia seed crude oil beneficial to individuals with hypertension, hyperglycemia, hyperlipidemia

A technology of Camellia oleifera seed crude oil and people, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems affecting the quality of finished oil, the effect of tea seed oil, deepening the color of tea oil, etc., to achieve cost reduction and sensitivity reduction , The effect of easy operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

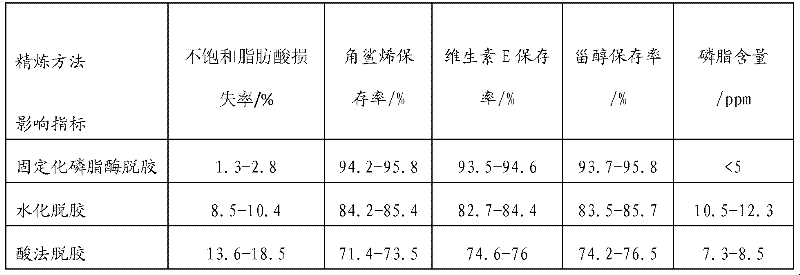

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the present embodiment, refining camellia seed crude oil with immobilized phospholipase A1 is realized through the following steps:

[0029] a. Add 5 mg of phospholipase A1 to 50 ml of HAc-NaAc or citric acid buffer solution with a pH value of 7 to obtain an enzyme solution. The concentration of phospholipase A1 in the enzyme solution is 1 mg / ml; the pretreated The macroporous resin and the enzyme solution are mixed at a volume ratio of 6:1 to obtain a mixed solution; the container containing the mixed solution is placed on a shaker and reacted at a speed of 150 rpm for 2 hours, and then added with a concentration of 0.03% The glutaraldehyde was cross-linked for 1 hour, and the cross-linking temperature was controlled at 3°C. The filter cake was collected by vacuum filtration, and the obtained was immobilized phospholipase A1. After dispersing the filter cake, put it in the refrigerator, and let it stand and dry at 0°C;

[0030] B, take the camellia seed crude oil an...

Embodiment 2

[0035] In the present embodiment, refining camellia seed crude oil with immobilized phospholipase A1 is realized through the following steps:

[0036]a, 20mg of phospholipase A1 is added to 100ml, and the pH value is 7 in HAc-NaAc or citric acid buffer solution to obtain enzyme liquid, the concentration of phospholipase A1 in the enzyme liquid is 1mg / ml; pretreated The macroporous resin and the enzyme solution are mixed at a volume ratio of 7:1 to obtain a mixed solution; the container containing the mixed solution is placed on a shaker and reacted at a speed of 170 rpm for 3 hours, and then added with a concentration of 0.1% The glutaraldehyde was cross-linked for 3 hours, and the cross-linking temperature was controlled at 3°C. The filter cake was collected by vacuum filtration, and the obtained was immobilized phospholipase A1. After the filter cake was dispersed, put it in the refrigerator, and let it stand and dry at 3°C;

[0037] B, take the camellia seed crude oil and r...

Embodiment 3

[0041] In the present embodiment, refining camellia seed crude oil with immobilized phospholipase A1 is realized through the following steps:

[0042] a, 50mg of phospholipase A1 is added to 500ml, and the pH value is 7 in HAc-NaAc or citric acid buffer solution to obtain enzyme liquid, the concentration of phospholipase A1 in the enzyme liquid is 3mg / ml; pretreated The macroporous resin and the enzyme solution are mixed at a volume ratio of 9:1 to obtain a mixed solution; the container containing the mixed solution is placed on a shaker and reacted at a speed of 180 rpm for 4 hours, and then added with a concentration of 0.24% The glutaraldehyde was cross-linked for 6 hours, and the cross-linking temperature was controlled at 15°C. The filter cake was collected by vacuum filtration, and the obtained was immobilized phospholipase A1. After the filter cake was dispersed, put it in the refrigerator, and let it stand and dry at 5°C;

[0043] B, take the camellia seed crude oil an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com