Device and method for removing glue from sample wafer

A sample and glue cavity technology, applied in the field of sample debonding devices, can solve the problems of loss of underlying silicon, damage to sensitive structures on the wafer surface, etc., to achieve no residue, mean square roughness and low silicon loss, and minimize the loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

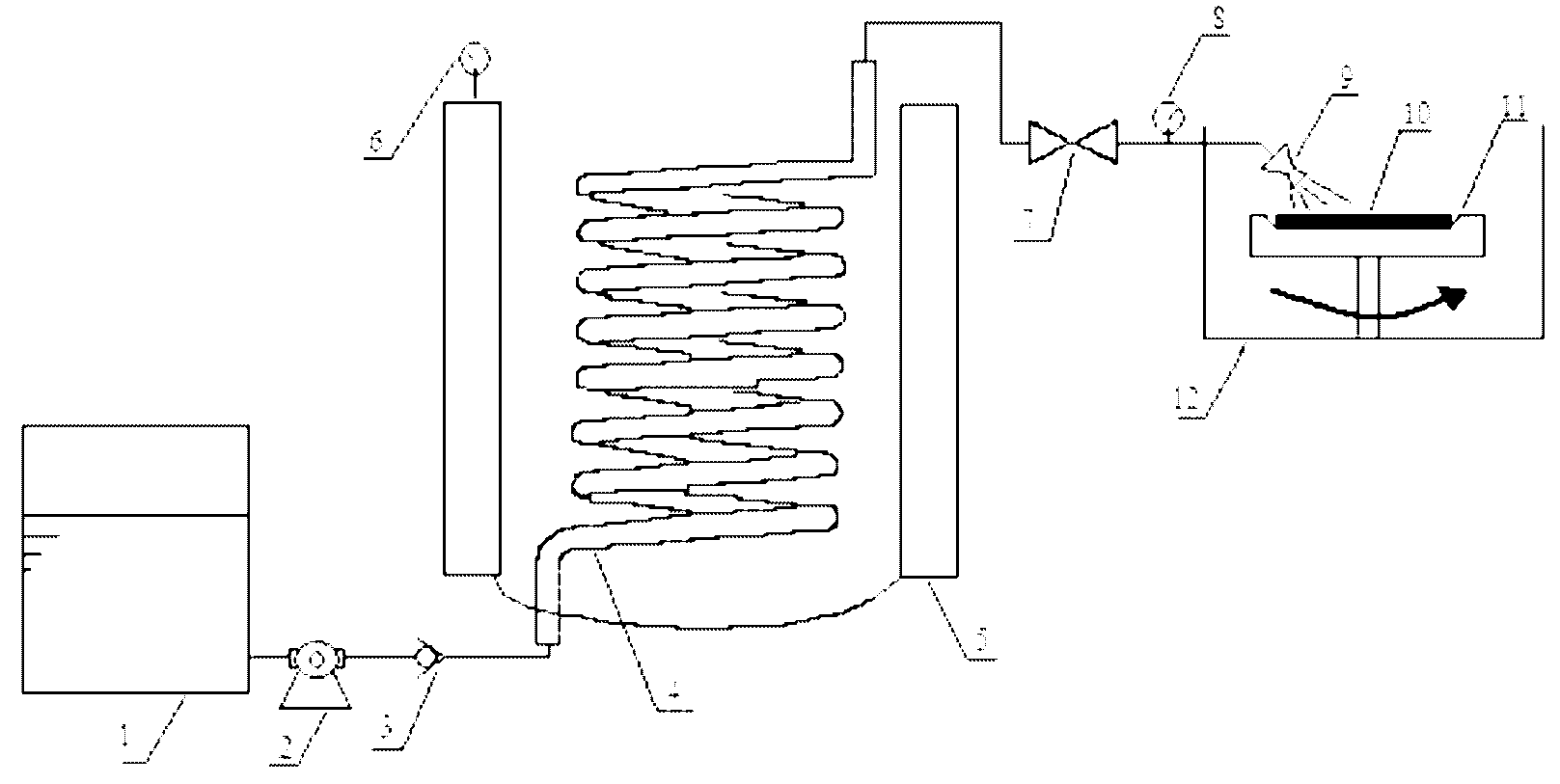

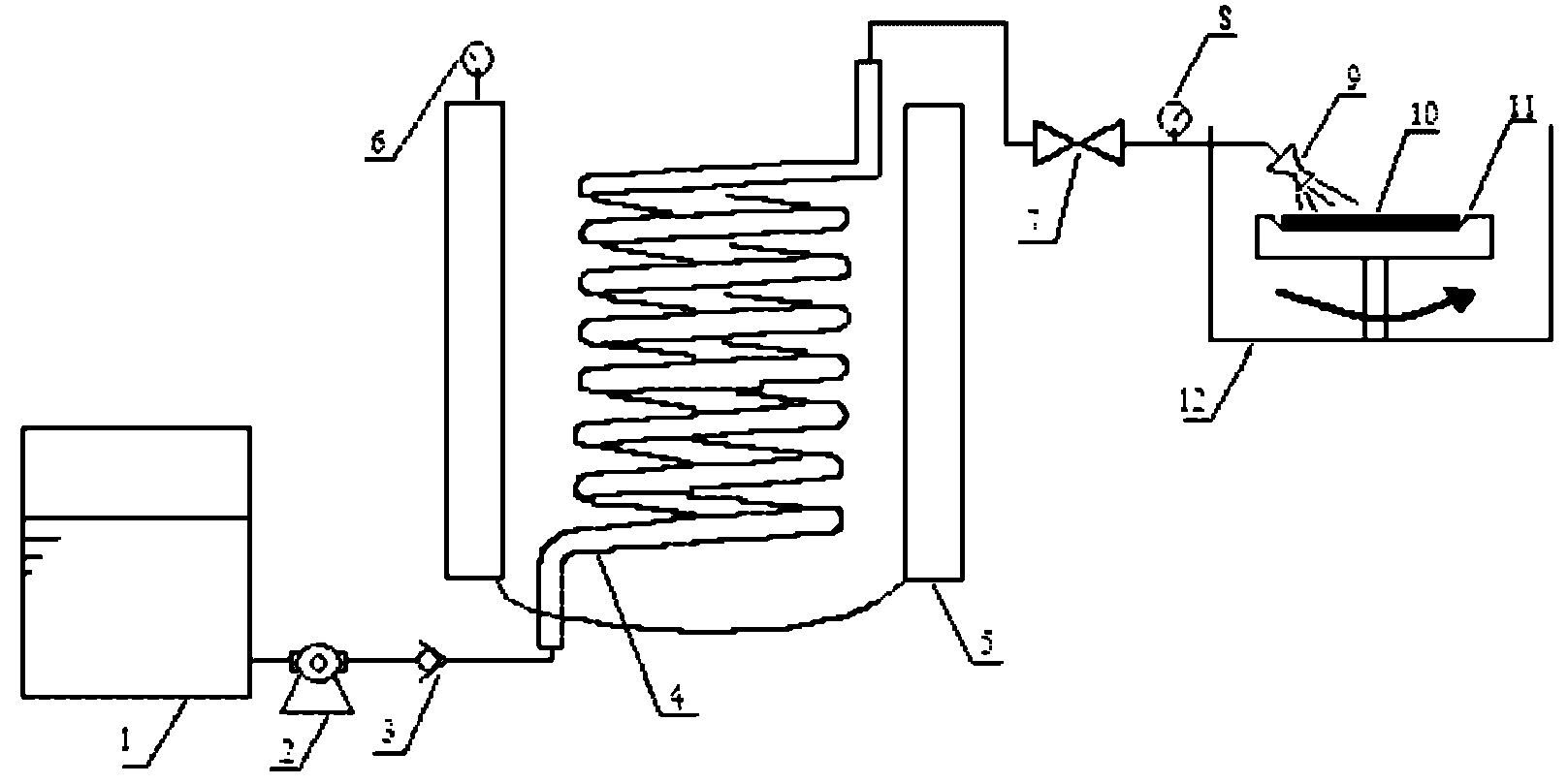

[0011] Such as figure 1 As shown, the sample stripping device provided by the embodiment of the present invention includes: a deionized water storage tank 1, a heat exchanger 4, a constant temperature heating device 5, a temperature display and control device 6, a glue removal chamber 12, and a nozzle 9. The outlet of the deionized water storage tank 1 is connected with a booster pump 2, and its outlet is connected to the inlet of the heat exchanger 4 through a one-way valve 3. The outlet of the heat exchanger 4 is connected to the inlet of the nozzle 9 via a valve 7. The heat exchanger 4 is made of Hastelloy, and the entire pipeline is coated with a fluorine coating. The constant temperature heating device 5 is made into a cylindrical cavity, and a heat exchanger 4 is arranged inside it. The thermostat heating device 5 is equipped with heat insulation materials outside. The heat exchanger 4 is fixed in the constant temperature heating device 5. A temperature control and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com