Method for preparing heparin sodium by combining enzymolysis and salt decomposition

A technology of joint preparation and heparin sodium, which is applied in the field of biochemical industry, can solve the problems such as the inability to release heparin sodium, achieve the effect of solving the problem of poisoning and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

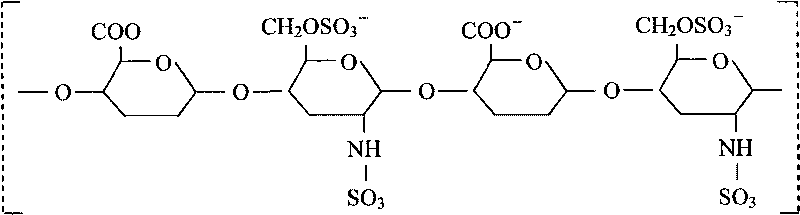

Method used

Image

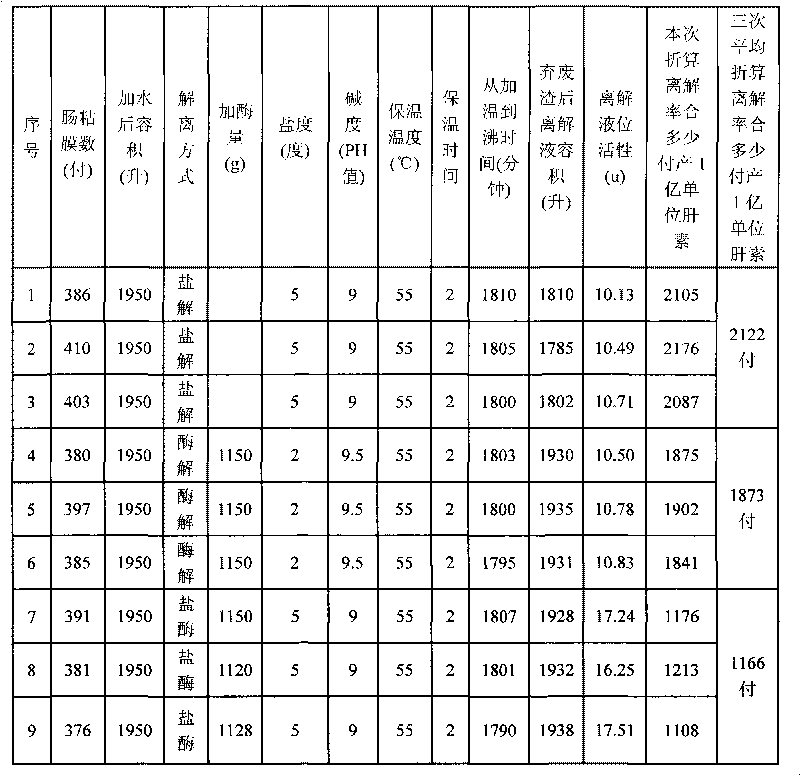

Examples

Embodiment 1

[0027] The specific steps of the present invention are as follows: before the test, the used utensils, reagents and consumables are autoclaved. Specific steps are as follows:

[0028] The purpose of the present invention is to solve the problem that simple salt hydrolysis and simple enzymatic hydrolysis cannot completely release heparin sodium from intestinal mucosal cells, that is, the combined process of salt hydrolysis and enzymatic hydrolysis can completely dissociate heparin from intestinal mucosal cells, thereby completely Extraction problem. And found more objective production parameters for industrial scale production.

[0029] The present invention realizes by following scheme:

[0030] 1) Dissociation: According to the weight ratio of water: pig small intestine mucosa is 4~5: 1, add water to the pig small intestine mucosa, and add salt to make the liquid salinity 5 degrees, add NaOH to adjust the pH value to 9, stir and heat up to 55°C, after 30 minutes of heat pr...

Embodiment 2

[0042] Pump out 400 pairs of pig small intestinal mucosa and water to account for 90% of the space in the reaction tank of 2000 liters, add 120 kilograms of salt, add alkali to adjust the pH value to 9, be warming up to 55 ℃, after insulated for 30 minutes, add alkaline protease ( 2709 type) 1000 grams, keep warm for 2 hours, then continue to heat up to 85°C, filter and cool to about 55°C.

[0043] (2) Add 8000 grams of basic resin Type 98 to the liquid at 55° C., stir and absorb for 8 hours, and filter to wash the resin.

[0044] (3) Add the same amount of 15°C saline as the resin, and perform elution twice, each time for 1 hour, and mix the above-mentioned elution water together.

[0045] (4) Add industrial alcohol to the upper eluent to make the alcohol concentration 45 degrees, let it stand for 24 hours, filter the lower sediment with polyester cloth, and dry it in a hot water bath at 65-75 ° C to obtain a purity of 90 The above activity units / mg heparin sodium product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com