PCB (Printed Circuit Board) drill bit and drilling machine with same

A drill and head technology, which is applied in the field of PCB drilling drills and drills using the drill, can solve the problems of low hole position accuracy of double-edged drills, easy-to-break drills, and difficult processing, so as to increase unit output value and reduce processing. Cost, the effect of increasing the number of laminated boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

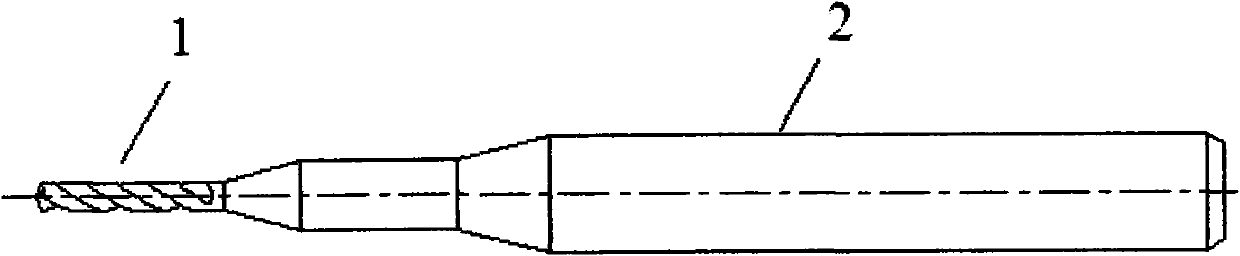

[0013] see figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of the PCB drilling bit of the present invention. The PCB drilling bit includes a drilling part 1 and an end handle part 2 connected thereto. The outer diameter of the bore part 1 is smaller than the outer diameter of the end shank part 2 .

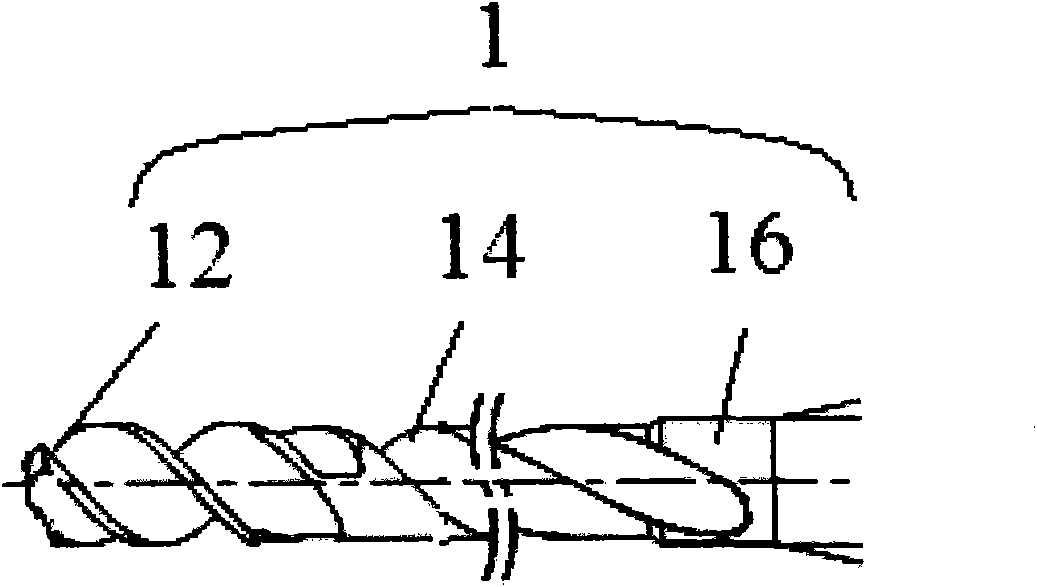

[0014] see figure 2 , figure 2 yes figure 1 Schematic diagram of the structure of the middle drilling part 1. The drilling part 1 of the PCB drilling bit includes a drilling head 12, a drilling neck 14 and a drilling root 16, and the drilling neck 14 and the drilling root 16 are provided with a helically extending chip removal main Grooves (not marked in the figure) are used for chip removal after punching the PCB substrate.

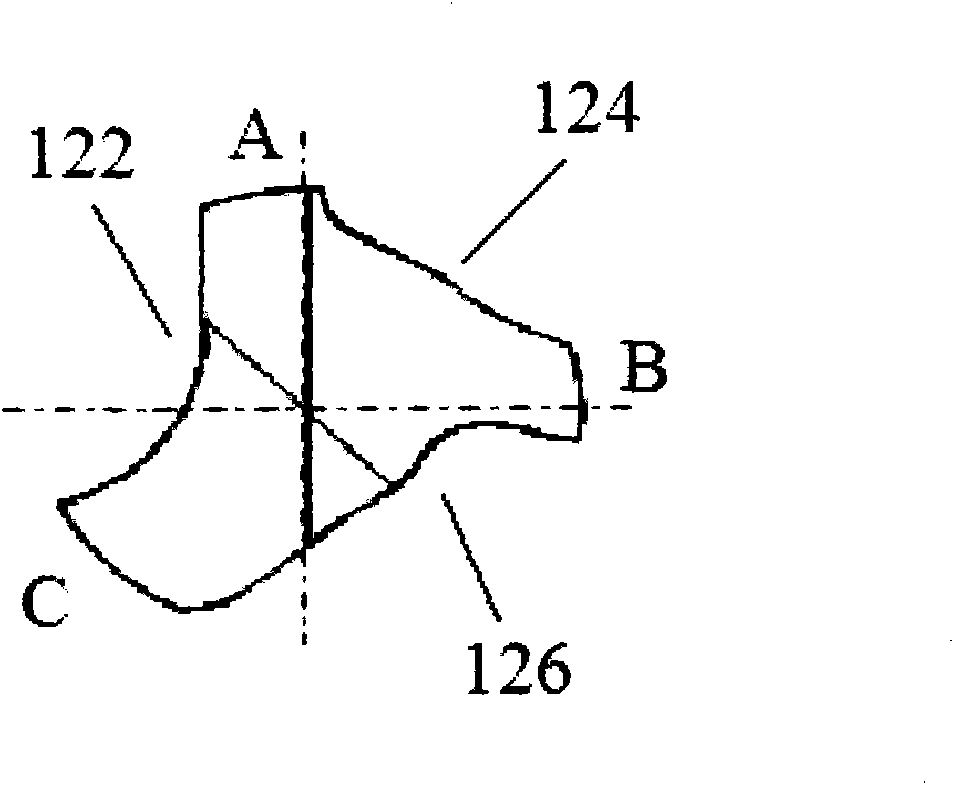

[0015] see image 3 , image 3 yes figure 2 Sectional view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com