Machining method of recombined puffed pigskin

A technology of puffed pigskin and processing methods, applied in the fields of application, food preparation, food science, etc., can solve problems such as difficult absorption of collagen, backlog of pigskin, and impact on large-scale production of products, so as to achieve rational and effective use of resources and expand use range, the effect of increasing the value of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

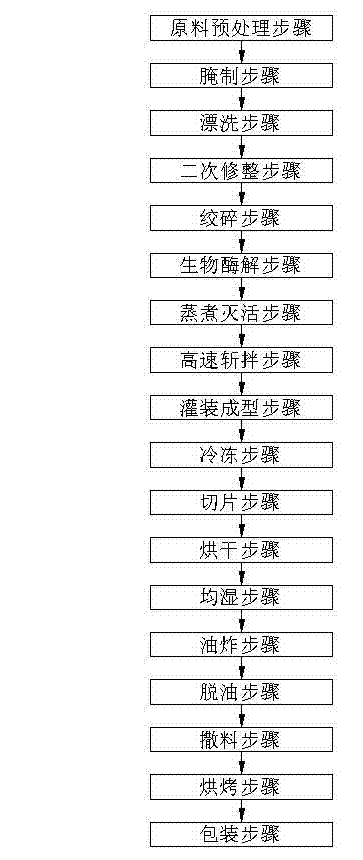

[0050] see figure 1 , the processing method of the recombined puffed pigskin in this embodiment sequentially includes a raw material pretreatment step, a pickling step, a rinsing step, a secondary trimming step, a mincing step, a biological enzymatic hydrolysis step, a cooking inactivation step, and a high-speed chopping step , Filling forming step, freezing step, slicing step, drying step, wet equalization step, frying step, deoiling step, sprinkling step, baking step and packing step, specifically as follows.

[0051] (1) Raw material pretreatment step.

[0052] Cut off the dirt and residual minced meat on the raw pigskin, scrape off the residual oil under the skin until the pores of the skin are exposed, then add the trimmed pigskin to clean water and wash it for 4 times until the water is colorless and free of impurities. Pre-treat the pork skin. In the present invention, the trimmed pigskin is usually washed for 3 to 5 times by adding clean water.

[0053] (2) Pickling...

Embodiment 2

[0104] see figure 1 , the processing method of the recombined puffed pigskin in this embodiment sequentially includes a raw material pretreatment step, a pickling step, a rinsing step, a secondary trimming step, a mincing step, a biological enzymatic hydrolysis step, a cooking inactivation step, and a high-speed chopping step , Filling forming step, freezing step, slicing step, drying step, wet equalization step, frying step, deoiling step, sprinkling step, baking step and packing step, specifically as follows.

[0105] (1) Raw material pretreatment steps: select the raw material pigskin, trim and clean it completely, and weigh 50Kg of pigskin.

[0106] (2) Pickling step: prepare 150Kg of pickling liquid, the mass percentage of sodium hydroxide contained in the pickling liquid is 0.2%, and the mass percentage of potassium phosphate contained in the pickling liquid is 0.3%. First add the pickling solution into the plastic basket and stir evenly, then pour the pretreated pigski...

Embodiment 3

[0124] see figure 1 , the processing method of the recombined puffed pigskin in this embodiment sequentially includes a raw material pretreatment step, a pickling step, a rinsing step, a secondary trimming step, a mincing step, a biological enzymatic hydrolysis step, a cooking inactivation step, and a high-speed chopping step , Filling forming step, freezing step, slicing step, drying step, wet equalization step, frying step, deoiling step, sprinkling step, baking step and packing step, specifically as follows.

[0125] (1) Raw material pretreatment step: select the raw material pigskin, after trimming and cleaning, weigh 50Kg of pigskin.

[0126] (2) Pickling step: prepare 150Kg of pickling liquid, the mass percentage of sodium hydroxide in the pickling liquid is 0.2%, and the mass percentage of potassium phosphate is 0.4%, add the pickling liquid into a plastic basket and stir evenly, put Pour the pigskin into a plastic basket, make it completely submerged, put it in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com