Preparation method of fish cartilage extracts and obtained product

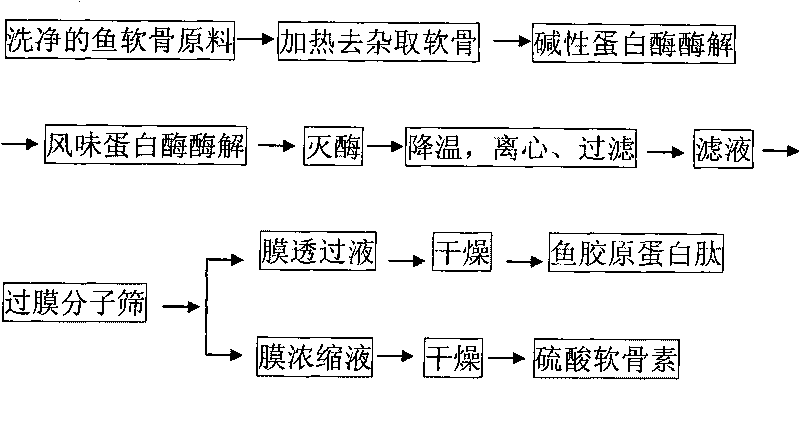

A technology of extract and cartilage, which is applied in the field of preparation of fish cartilage extract, can solve the problems of raw material pollution threat steps, high active ingredient content, insufficient raw material utilization, etc., achieve simple process flow, high recovery rate, and improve raw material utilization value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take an appropriate amount of cleaned salmon (Oncorhynchnchus Spp.) head, heat in a reaction tank at 100°C for 10 minutes, separate 500 g of cartilage and pulverize it with a homogenizer, add 500 g of water, adjust the pH to 8.5 with 10% sodium hydroxide, and add 0.1 % Alcalase 3.0T alkaline protease at 65°C for 1 hour, adjust the pH to 6.5 with 1% hydrochloric acid, add 0.05% of raw material weight Novo-flavored protease at 65°C for 2 hours. Heat up to 95°C to kill enzymes, cool down to 70°C, centrifuge at 4000r / min for 30min, filter to remove impurities, add 80g of white coarse diatomaceous earth to aid in filtration, dilute the filtrate with water to 2 times the mass of the filtrate, and pass through a coiled membrane with a molecular weight cut-off of 5000 Molecular sieves, under the conditions of 50°C and a pressure of 2 kg / cm2, carry out molecular weight cutting, circulate and separate for 1 hour, collect the membrane permeate, concentrate it under reduced pressure...

Embodiment 2

[0036] Take an appropriate amount of cleaned Raja porosa, heat in a reaction tank at 85°C for 20 minutes to remove impurities, separate 500 g of cartilage and pulverize it with a homogenizer, add 500 g of water, adjust the pH to 7.5 with 10% sodium hydroxide, add cartilage 0.2% by weight of Alcalase 3.0T alkaline protease was hydrolyzed at 55°C for 0.5h, the pH was adjusted to 6.0 with 1% hydrochloric acid, and 0.2% by weight of cartilage Novo flavored protease was added to enzymolyze at 55°C for 1h. Heat up to 85°C to inactivate the enzyme, cool down to 50°C, centrifuge at 4000r / min for 30min, filter to remove impurities, and add 80g of kaolin to filter. Dilute the filtrate with water to 2 times the quality of the filtrate, pass through a tubular membrane molecular sieve with a molecular weight cut-off of 5000, cut the molecular weight under the conditions of 70°C and a pressure of 2 kg / cm2, circulate and separate for 1.5h, collect the membrane permeate and concentrate it unde...

Embodiment 3

[0039] Take an appropriate amount of cleaned shark (prionace glauca (Linnaeus)) bone, heat it in a water bath at 75°C for 30 minutes to remove impurities, separate 500 g of cartilage and pulverize it with a homogenizer, add 600 g of water, and adjust the pH to 9 with 10% sodium hydroxide. Add 0.25% of raw material weight Alcalase 2.4L alkaline protease for enzymolysis at 50°C for 0.5h, adjust the pH to 6.8 with 1% hydrochloric acid, add 0.25% raw material weight of Novo flavor protease for enzymolysis at 50°C for 0.5h. Heat up to 80°C to kill the enzyme, cool down to 45°C, centrifuge at 2000r / min for 40min, filter to remove impurities, add 80g of diatomaceous earth to help filter, dilute the filtrate with water to 2 times the quality of the filtrate, pass through a hollow fiber membrane molecular sieve with a molecular weight cut off of 15000 Under the condition of lower than 50°C and pressure of 1.5 kg / cm2, carry out molecular weight cutting, circulate and separate for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com