Method for simultaneously extracting soybean peptide and soybean oligosaccharide from aqueous phase produced through aqueous enzymatic method

A technology for simultaneous extraction of soybean oligosaccharides, applied in the direction of oil/fat production, fermentation, and fat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Screening experiment of ultrasonic treatment process condition parameters

[0033] 1 Materials and methods

[0034] 1.1 Materials and reagents

[0035]

[0036] 1.2 Main instruments and equipment

[0037]

[0038] 1.3 Experimental method

[0039] 1.3.1 Determination of soybean components

[0040] Determination of moisture: GB304-87; Determination of crude fat: Soxhlet extraction method in GB5512-85; Determination of crude protein: GB6432-94 standard method; Determination of ash: GB5009.4-85.

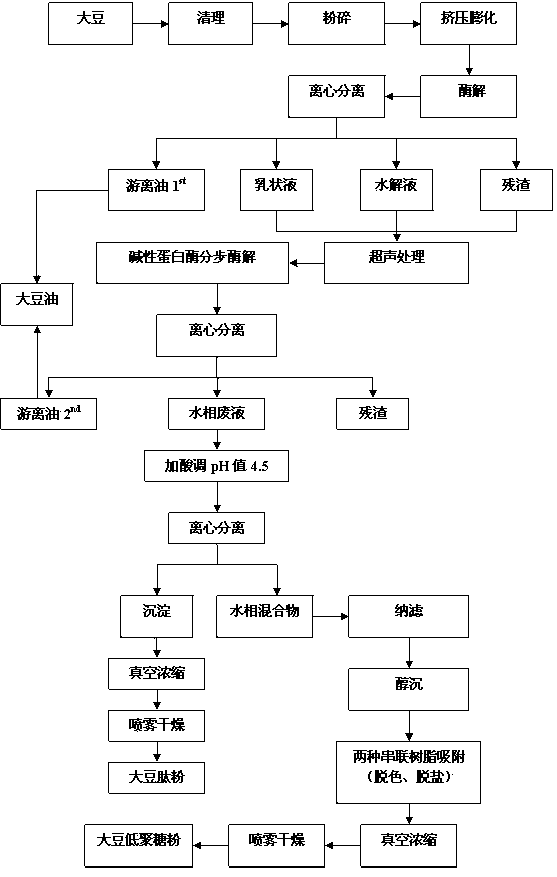

[0041] 1.3.2 Process flow (see figure 1 )

[0042] 1.3.3 Determination of soybean polypeptide yield: Kjeldahl method.

[0043]

[0044] In the formula ——Soluble nitrogen in 10%TCA, mg

[0045] ——total nitrogen in raw soybean, mg

[0046] 1.3.4 Determination of extraction rate of soybean oligosaccharides:

[0047]

[0048] 2 Results and Discussion

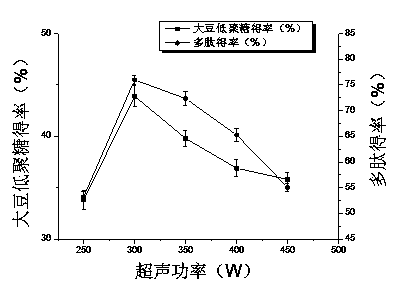

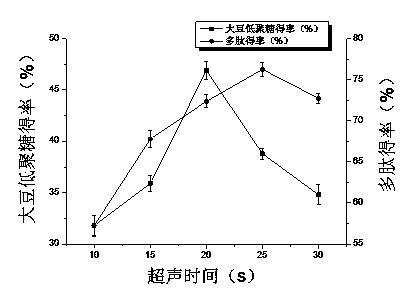

[0049] 2.1 Effect of single factor condition of ultrasonic treatment process on the yield of soybe...

Embodiment 2

[0079] Example 2 Screening experiment of alcohol precipitation treatment process condition parameters

[0080] 1 Materials and methods

[0081] 1.1 Materials and reagents

[0082]

[0083] 1.2 Main instruments and equipment

[0084] equipment factory centrifuge Beijing Medical Centrifuge Factory RE-52A rotary evaporator Shanghai Yarong Biochemical Instrument Factory

[0085] 1.3 Experimental method

[0086] 1.3.1 Process flow (see figure 1 )

[0087] 1.3.2 Determination of extraction rate of soybean oligosaccharides:

[0088]

[0089] 2 Results and Discussion

[0090] 2.1 Effect of alcohol precipitation treatment on the yield of soybean oligosaccharides

[0091] 2.1.1 Effect of ethanol concentration on yield of soybean oligosaccharides

[0092] Under the conditions of ethanol extraction time of 90min and ethanol extraction temperature of 40°C, the influence of ethanol concentration on the yield of soybean oligosaccharides was investi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com