Method for preparing soybean peptides through enzymolysis of soy protein

A technology for enzymatic hydrolysis of soybean protein and soybean protein isolate, applied in protein food processing, vegetable protein processing, protein food ingredients, etc., can solve the problems of no sensory evaluation and molecular weight distribution, etc., and achieve low bitterness, high yield, programmatic simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

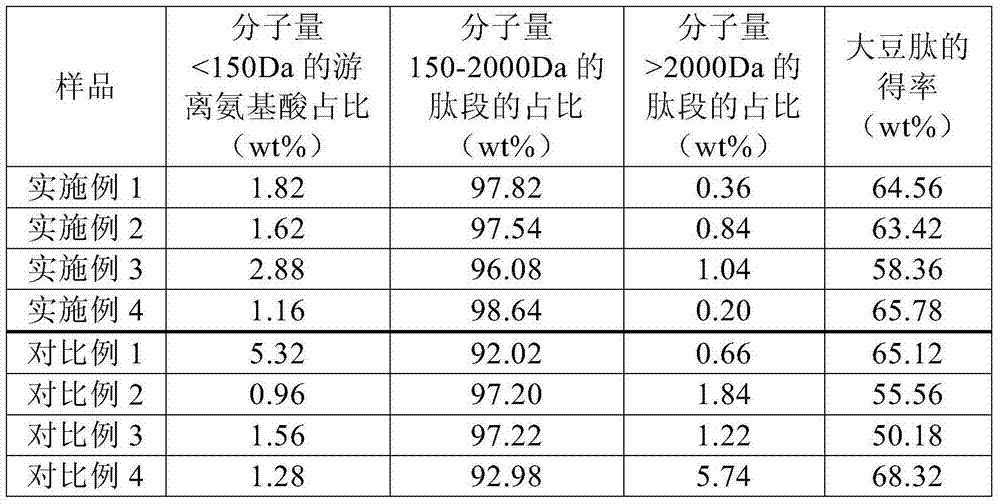

Examples

Embodiment 1

[0056] Soy protein isolate is prepared by adding water to a 4wt% soybean protein isolate liquid, and the pH is adjusted to 7.0 with 2mol / L sodium hydroxide or 2mol / L phosphoric acid solution, and the temperature is adjusted to 60°C, relative to the dry weight of soybean protein isolate In other words, first add 2wt% Alkaline protease (Danisco) and 0.5wt% Alphalase (Danisco), and then add 1wt% Foodpro51FP (Danisco) for 1 hour of enzymolysis. After the enzymolysis, adjust the enzymatic hydrolysis Solution pH to 4.5, heat at 75°C for 30min to inactivate enzyme, centrifuge at 1000g for 10min, take supernatant, add to jet cooker (ESCS-M103, Shanghai Xiaole Dongchao Biotechnology Development Co., Ltd.), and sterilize at 130°C 90s, and then spray-dry to obtain soybean peptide products. Wherein, the spray-drying equipment controls the inlet temperature to be 200°C and the outlet temperature to be 100°C.

Embodiment 2

[0058] Soybean protein isolate is prepared by adding water to 12wt% soybean protein isolate liquid, and the pH is adjusted to 5.0 with 2mol / L sodium hydroxide or 2mol / L hydrochloric acid solution, and the temperature is adjusted to 30°C, relative to the dry weight of soybean protein isolate In other words, first add 5wt% Alcalase2.4L FG (Novozymes) and 5wt% Neutrase0.8L (Novozymes) for 3 hours, then add 0.1wt% Flavourzyme (Novozymes) for 3 hours. After the enzymatic hydrolysis, adjust the pH of the enzymatic solution to 4.0, heat at 85°C for 20 minutes to inactivate the enzyme, centrifuge at 3000g for 20 minutes, take the supernatant, and add it to a jet cooker (ESCS-M103, Shanghai Xiaole Dongchao Biotechnology Development Co., Ltd.) sterilized at 100°C for 120s, and then spray-dried to obtain soybean peptide products. Wherein, the spray drying equipment controls the inlet temperature to be 170°C and the outlet temperature to be 70°C.

Embodiment 3

[0060] Soy protein isolate is prepared by adding water to 10wt% soybean protein isolate liquid, and the pH is adjusted to 9.0 with 2mol / L sodium hydroxide or 2mol / L hydrochloric acid solution, and the temperature is adjusted to 45°C, relative to the dry weight of soybean protein isolate In other words, first add 0.5wt% Alcalase2.4L FG (Novozymes) and 2wt% Neutrase0.8L (Novozymes) for 2 hours, then add 3wt% Flavourzyme (Novozymes) for 2 hours. After the enzymatic hydrolysis, adjust the pH of the enzymatic solution to 5.0, heat at 95°C for 10 minutes to inactivate the enzyme, centrifuge at 5000g for 30 minutes, take the supernatant, and add it to a jet cooker (ESCS-M103, Shanghai Xiaole Dongchao Biotechnology Development Co., Ltd.) sterilized at 180°C for 30s, and then spray-dried to obtain soybean peptide products. Wherein, the spray drying equipment controls the inlet temperature to be 150°C and the outlet temperature to be 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com