Color silk floss quilt and preparation method thereof

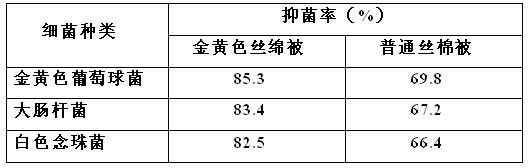

A silk quilt and color technology, applied in textiles and papermaking, fiber processing, biochemical fiber processing, etc., can solve the problems of pigment loss, inability to obtain color appearance silk quilt, etc., to prevent the loss of pigments, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

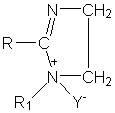

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a colored silk quilt, comprising the steps of:

[0026] (1) Blanking golden silk cocoons in a silk floss machine, spraying with a spray liquid to make a silk floss sheet; the spray liquid is a mixed solution of sodium hydroxide and softener SCM, wherein the sodium hydroxide The mass concentration is 1 g / L, the mass concentration of the softener SCM is 2 g / L, the spray temperature is 55°C, and the spray time is 1.5 min;

[0027] (2) The obtained silk floss sheet is refined and degummed in a degumming solution containing 2709 alkaline protease, the degumming time is 120min, the bath ratio is 1:40, the temperature is 42°C, and the consumption of the alkaline protease is 45 activity units / ml, the pH value is 10;

[0028] (3) The temperature of the degumming solution is raised to above 95° C. and kept for 45 minutes to inactivate the alkaline protease;

[0029] (4) Washing, finishing, dehydration, drying, loosening by hand, and making colored silk q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com