Preparation process for strong-flavor tea-seed oil and prepared strong-flavor tea-seed oil

A preparation process, tea seed oil technology, applied in the direction of edible oil/fat, fat oil/fat production, fat production, etc., can solve the problem of camellia oleifera fragrance loss, etc., to achieve the effect of strong fragrance, stable process and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preparation process of strong fragrance tea seed oil, comprising the following steps:

[0018] (1) Pulverizing the Camellia oleifera seed meal through a 60-mesh sieve;

[0019] (2) The pulverized material is heated to 190°C by microwave,

[0020] (3) The high-temperature pulverized material through microwave is added into normal temperature water according to the water-to-material ratio of 1:1 to make slurry;

[0021] (4) Add alkaline protease to the slurry, adjust the pH of the slurry to 8, and carry out ultrasonic enzymolysis at 55° C. for 3 hours. The amount of alkaline protease added is 2% of the camellia oleifera seed meal powder, and the enzymolysis ends Afterwards, carry out high temperature to inactivate the enzyme, and centrifuge to separate the enzymolysis solution. The ultrasonic generator is an H66025 ultrasonic generator with an ultrasonic frequency of 22kHz and an ultrasonic power of 250W;

[0022] (5) Add the cold-pressed tea seed essential oil to the...

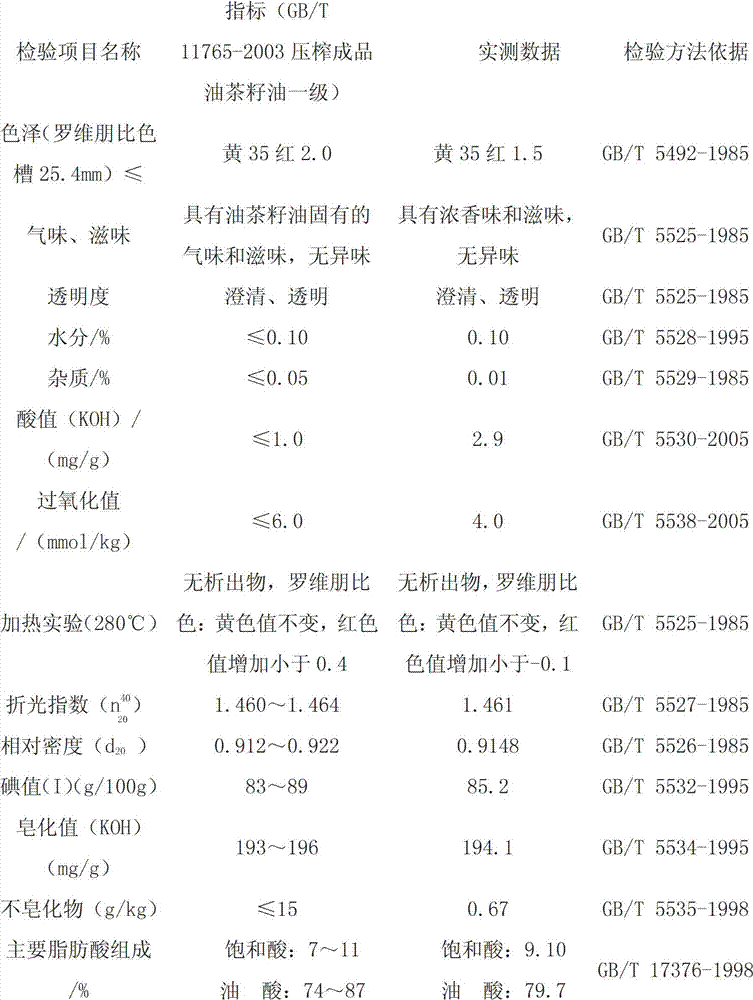

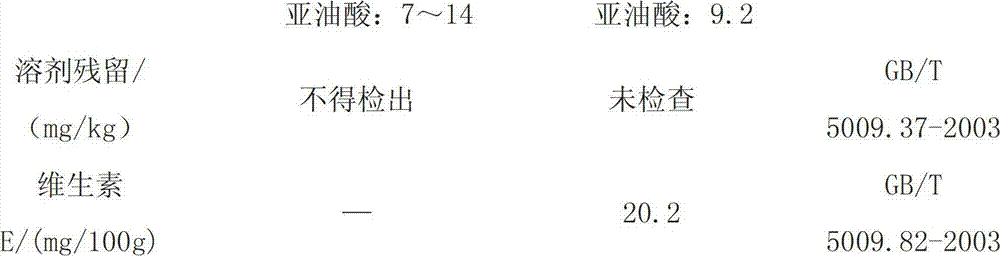

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com