Method of breaking yeast cell wall and preparing yeast extract

A technology of yeast extract and yeast cells, which is applied in the field of yeast cell wall breaking and preparation of yeast extract, which can solve the problems of lack of nutrients, complex reaction conditions, and high requirements for wall breaking agents, so as to improve protein content and amino state Nitrogen content, high wall breaking rate, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

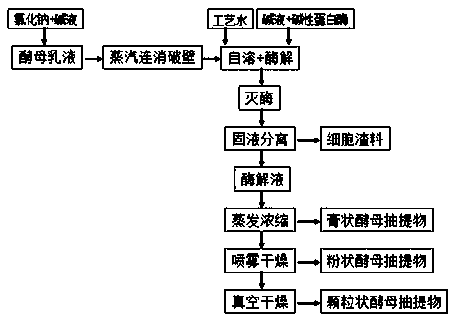

Image

Examples

example 1

[0043] A method for breaking yeast cell walls and preparing yeast extract, comprising the following steps:

[0044] Take the centrifuged and washed bread yeast slurry, adjust it with water to make 30% yeast emulsion, add 3% sodium chloride by mass percentage, and adjust the pH value of the yeast emulsion to 8.50. Using the steam continuous elimination method, the steam tubes are maintained at 135°C, and the continuous elimination of the wall is broken for 15s. Then dilute with water to adjust the concentration of the yeast emulsion to 15%, adjust the temperature to 55°C, confirm and adjust the pH value of the diluted yeast emulsion to 8.50, and add 0.05% alkaline protease according to the mass ratio of the emulsion ( Alkaline Protease ), kept at about 55°C, and stirred for 5 hours. Adjust the pH of the enzymolysis solution to 7.0, heat the temperature up to 95°C, and maintain it for 20 minutes to inactivate the enzyme. Use a centrifuge for centrifugal separation, and use a f...

example 2

[0047] A method for breaking yeast cell walls and preparing yeast extract, comprising the following steps:

[0048] Take the centrifuged and washed bread yeast slurry, adjust it with water to make 30% yeast emulsion, add 3% sodium chloride by mass percentage, and adjust the pH value of the yeast emulsion to 8.50. Using the steam continuous elimination method, the steam tubes are maintained at 130°C, and the continuous elimination of the wall is broken for 60s. Then dilute with water to adjust the concentration of the yeast emulsion to 15%, adjust the temperature to 55°C, confirm and adjust the pH value of the diluted yeast emulsion to 8.50, and add 0.06% alkaline protease according to the mass ratio of the emulsion ( Alkaline Protease ), insulated at about 55°C, and stirred for 4 hours for enzymatic hydrolysis. Adjust the pH of the enzymolysis solution to 7.0, heat the temperature up to 90°C, and maintain it for 30 minutes to inactivate the enzyme. Use a centrifuge for centr...

example 3

[0051] A method for breaking yeast cell walls and preparing yeast extract, comprising the following steps:

[0052] Take bread yeast puree, prepare 35% yeast emulsion with water, add 5% sodium chloride by mass percentage, and adjust the pH value of yeast emulsion to 8.50. Using the steam continuous elimination method, the steam tubes are maintained at 130°C, and the continuous elimination of the wall is broken for 60s. Then dilute with water to adjust the concentration of the yeast emulsion to 15%, adjust the temperature to 55°C, confirm and adjust the pH value of the diluted yeast emulsion to 8.50, and add 0.06% alkaline protease according to the mass ratio of the emulsion ( Alkaline Protease ), kept at about 55°C, and stirred for 6 hours. Adjust the pH of the enzymolysis solution to 7.0, heat the temperature up to 95°C, and maintain it for 20 minutes to inactivate the enzyme. Use a centrifuge for centrifugal separation, and use a five-effect evaporation concentrator to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com