Cutter wheel for cutting glass materials and processing method thereof

A technology of glass materials and processing methods, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., and can solve problems such as areas that cannot be removed with a certain depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

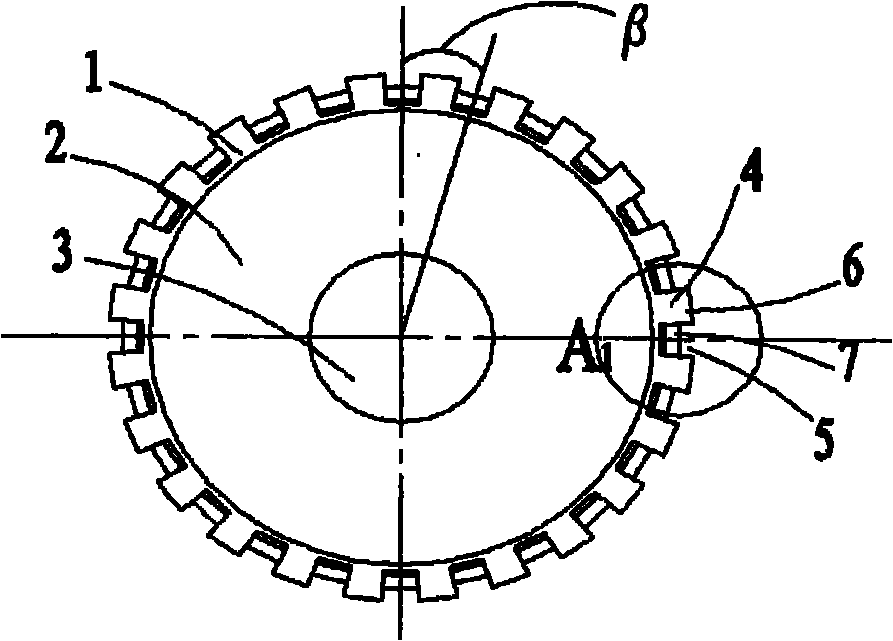

[0050] Below combined with Figure 1 to Figure 5 A cutter wheel for cutting glass material and its processing method according to the present invention are described in detail.

[0051] The invention provides a disc-shaped cutter wheel capable of cutting glass materials, especially glass materials with a thickness of 0.1 mm to 2 mm, which is mainly obtained by processing a special microstructure at the V-shaped cutting edge of a commonly used disc-shaped cutter wheel A cutter wheel with a new structure.

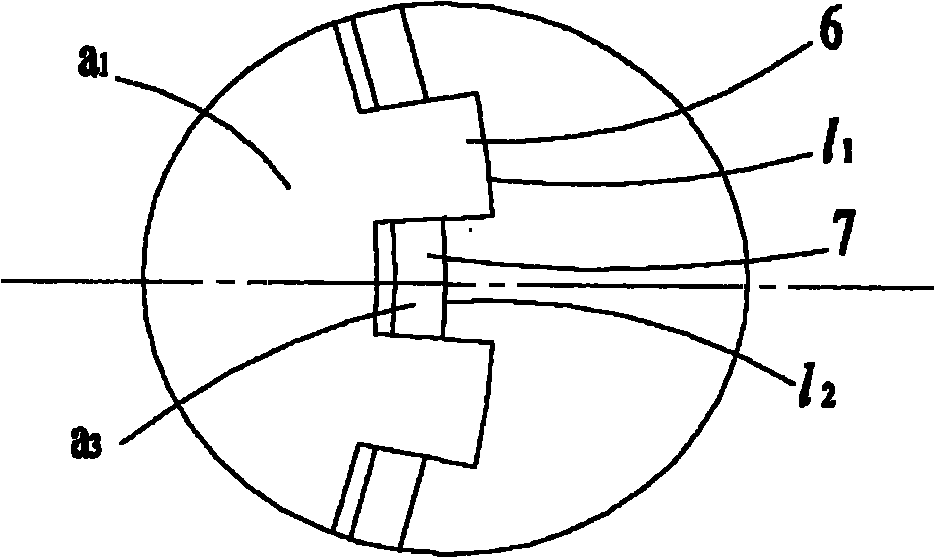

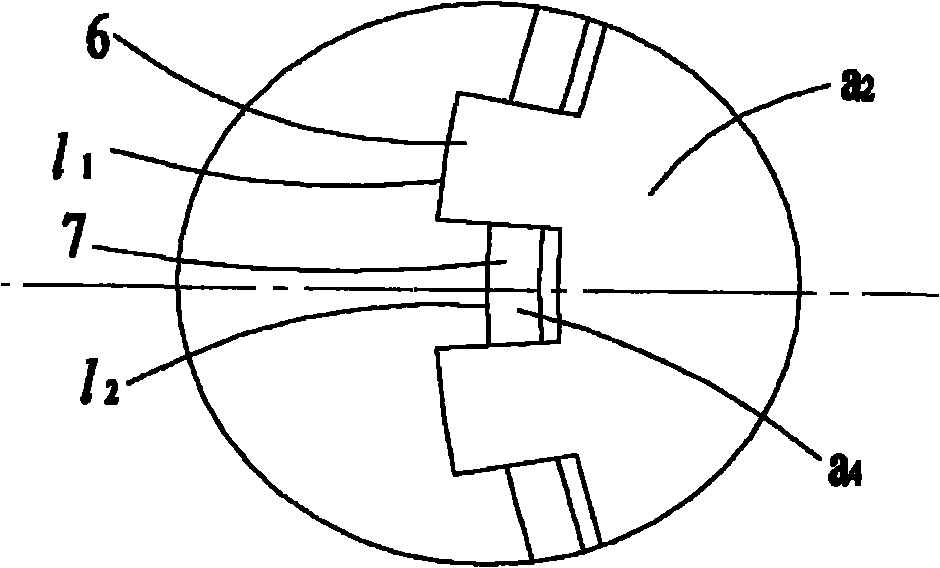

[0052] Among them, the V-shaped disc cutter wheel has a curved surface a 1 and a 2 And the V-shaped cutting edge portion 1 that edge ridge line 1 forms, the cutter wheel disk surface 2 and the cutter wheel center are used for fixing the shaft hole 3 of the cutter wheel. The material of the cutter wheel is polycrystalline or polycrystalline diamond, or it can be diamond, cemented carbide, or a composite of these materials; the thickness of the cutter wheel ranges from 0.3mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com