Method for determining reasonable width of gob-side entrydriving narrow coal pillar

A definite method and narrow coal pillar technology, which is applied in earthwork drilling, surface mining, underground mining, etc., can solve problems affecting the recovery rate of mining areas, difficulties in roadway maintenance, and affecting safe mining of working faces, so as to reduce the amount of maintenance engineering and maintenance costs, ensuring long-term stability, high theoretical significance and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

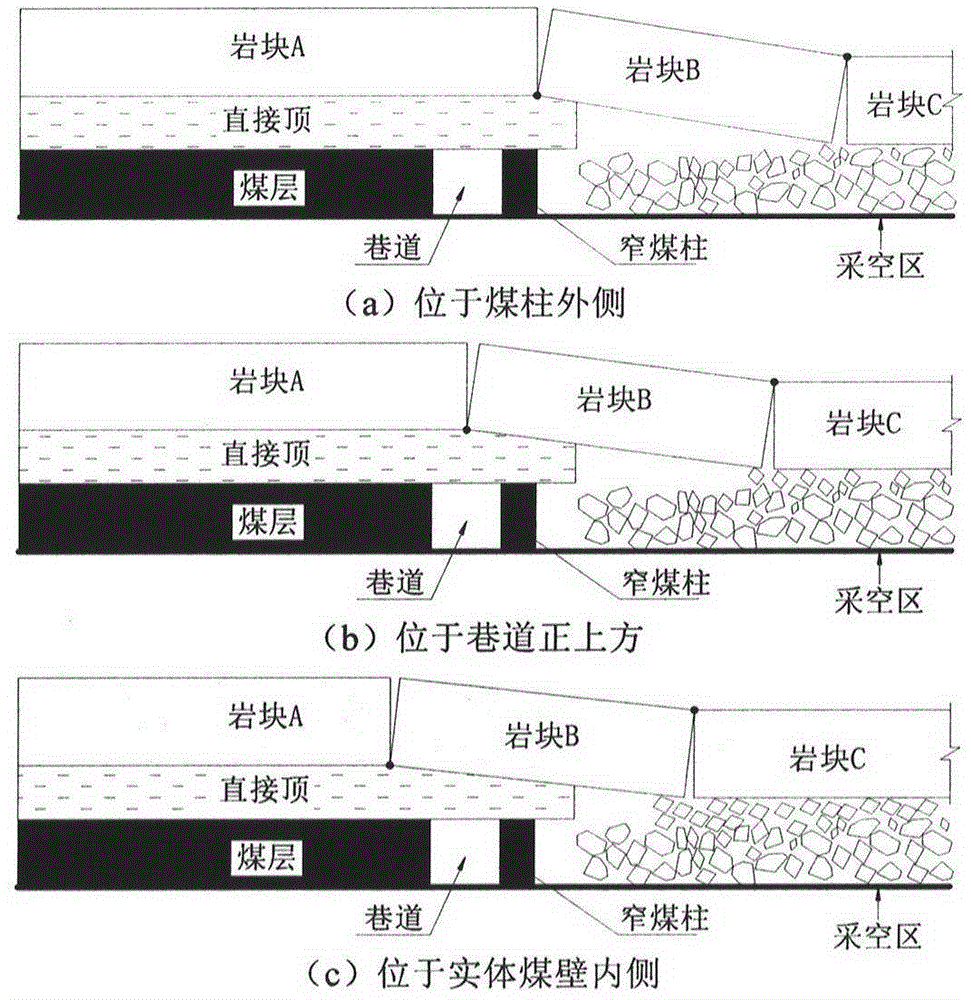

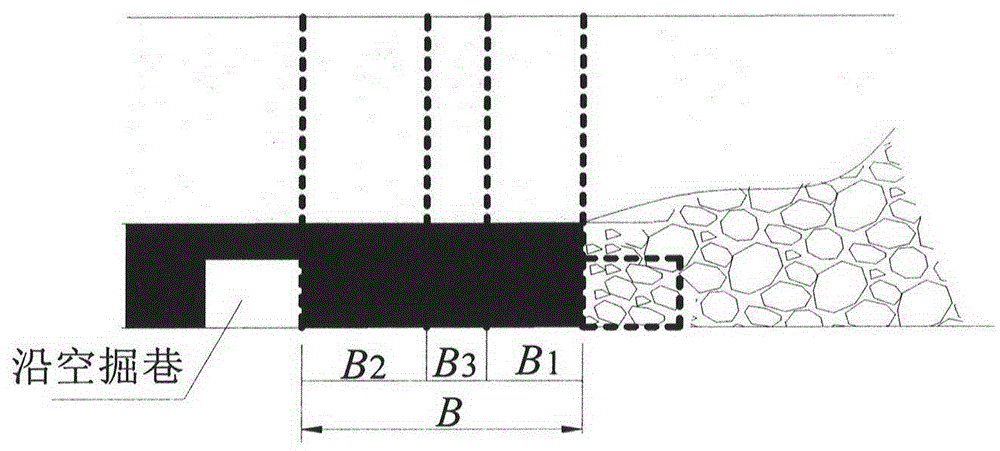

[0040] 1 Overview of engineering geological conditions

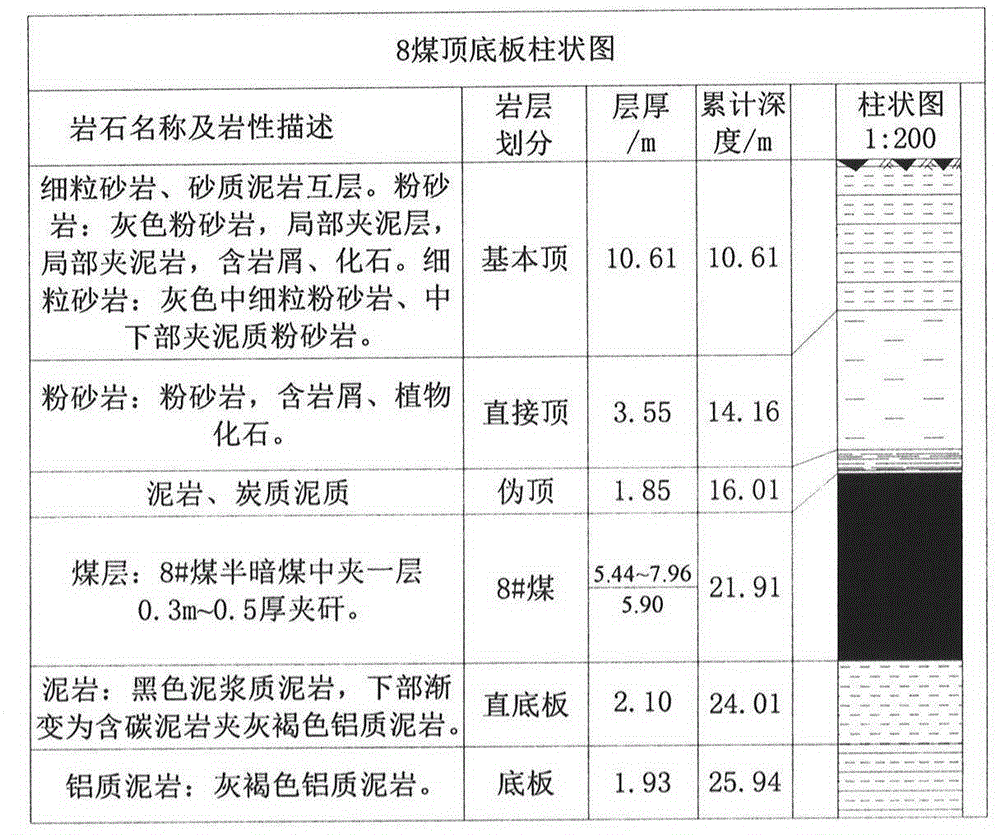

[0041]The 8105 working face of a certain mine has a strike length of 1360m, a mining face length of 200m, fully mechanized caving mining, a mining height of 3.2m, and a mining depth of 500m. The east of the 8105 working face is the coal pillar of Caojia Village, the south is the 8104 goaf, the west is the 8 coal 3 downhill, and the north is the 8106 goaf. The thickness of 8 coal is 5.44-7.96m, the average is 5.90m, the dip angle is 4°, f=2-3, and the occurrence is stable. The direct roof of coal 8 is gray-black mudstone, sandy mudstone interbedded with powder-fine-grained sandstone, with a thickness of 0.00-6.55m, which is a weak and unstable roof that is prone to caving. The basic roof is medium to fine-grained siltstone, which is a relatively stable roof with weak-medium hardness. The floor is taupe aluminous mudstone, with a thickness of 0.71-16.01m. It is a moderately hard and relatively stable floor, which swells ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com