High-permeability glass cutter wheel with chamfer on side edge of concave part of cutting edge

A glass cutting and concave side technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass cutting obstruction, easy breakage of tooth tips, and reduced cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

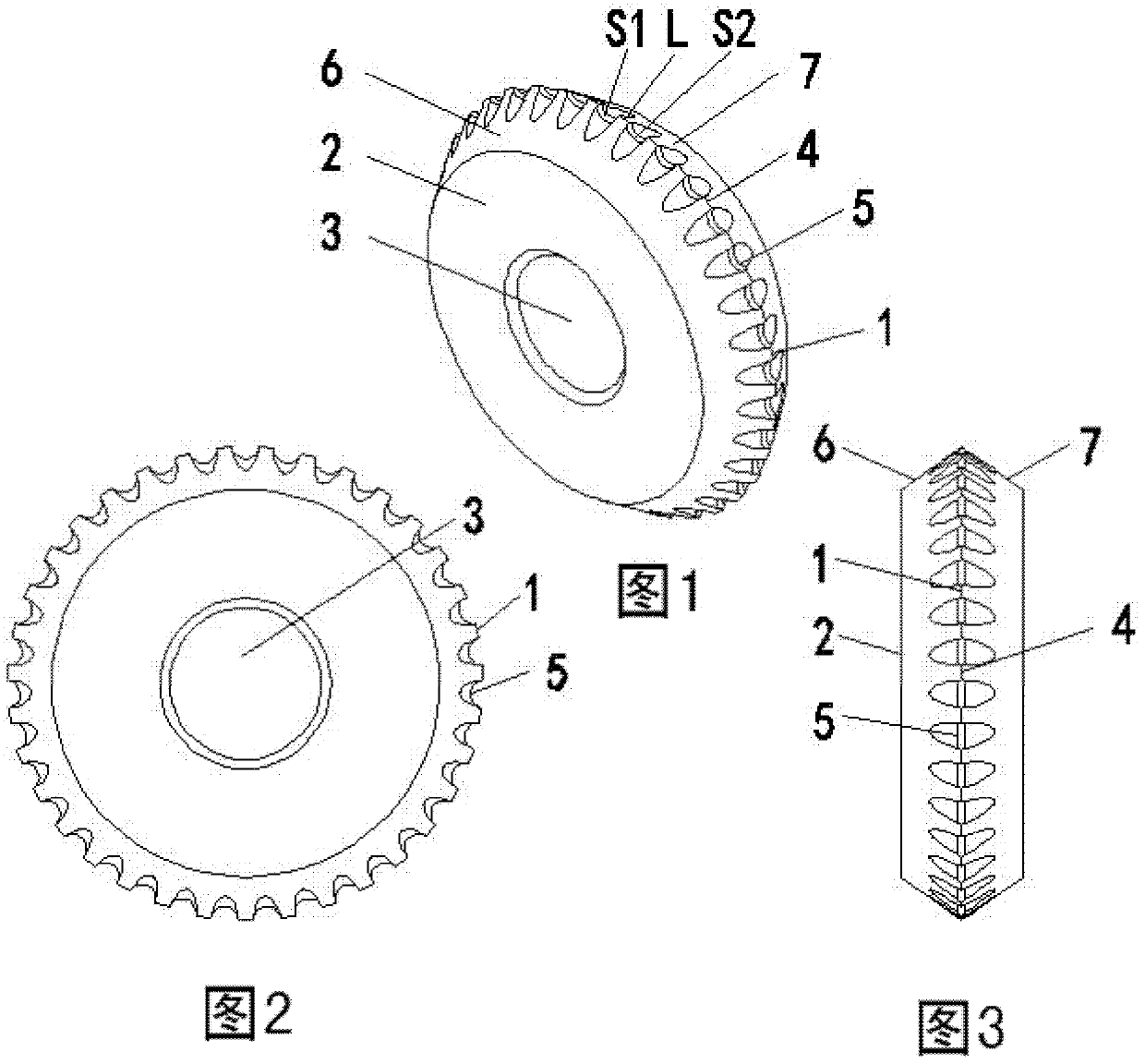

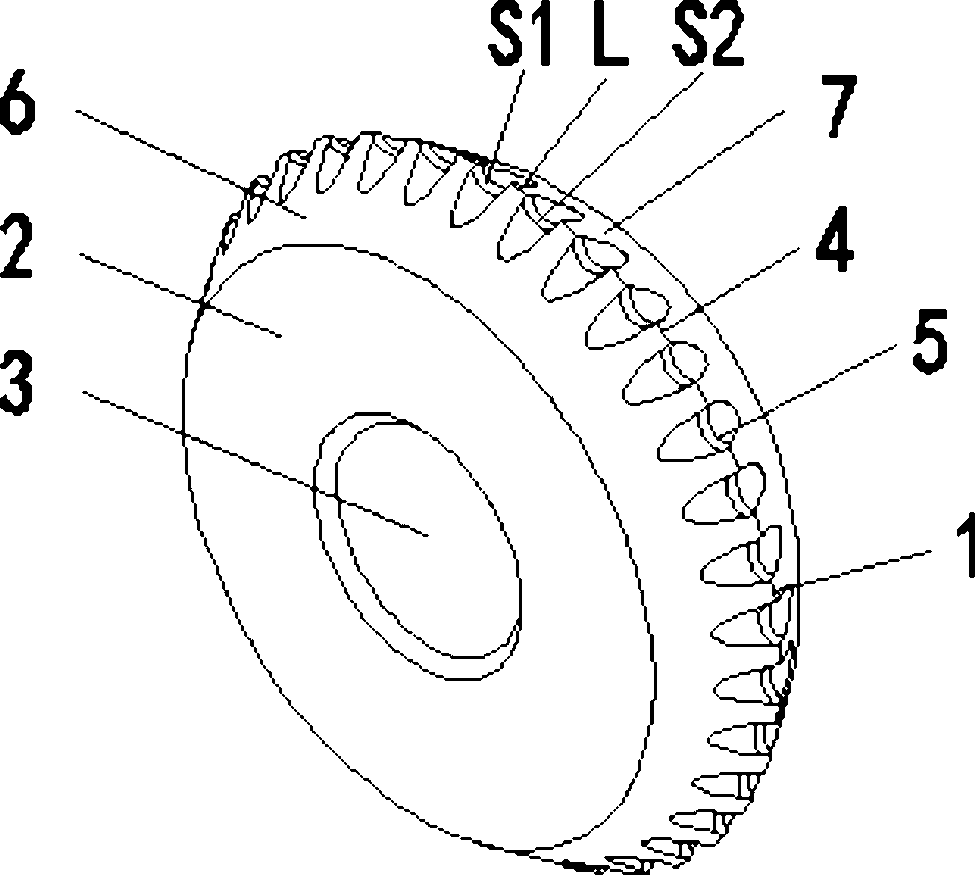

[0021] Embodiment 1: as Figure 1 to Figure 3 As shown, the present invention discloses a high-permeability glass cutting cutter wheel with a concave edge and chamfered side edges. The cutter wheel has a V-shaped cutting edge 1 , a disk surface 2 and a shaft hole 3 .

[0022] The V-shaped cutting edge portion 1 is formed by a first curved surface S1, a second curved surface S2 and an outer edge ridgeline L. As shown in FIG.

[0023] The outer edge ridge line L of the V-shaped cutting edge portion 1 has cutting edges 4 and recessed structures 5 distributed alternately around the circumference, and the side edges of the recesses 5 are processed with symmetrical first chamfering slopes 6 and second chamfering slopes 7 .

[0024] A high-permeability glass cutting wheel with chamfers on the concave side edges of the cutting edge, the cutting edge 1 has regularly distributed depressions 5, and symmetrical first chamfering slopes 6 are processed on both sides of the side edges of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com