PA6/MgO thermal-conductive composite material and preparation method thereof

A heat-conducting composite material and mixing technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high cost, wear and tear of production equipment, achieve low cost, increase the degree of close packing, and facilitate industrial promotion and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

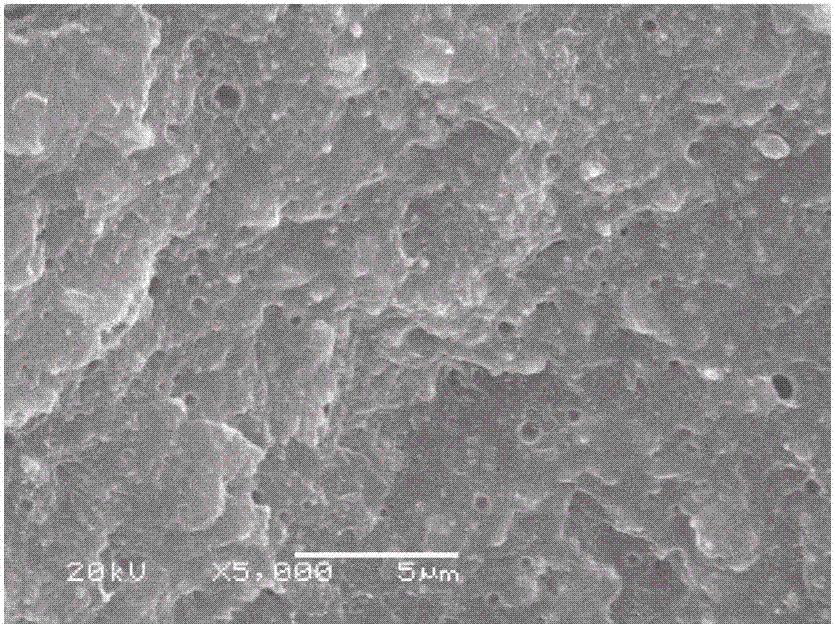

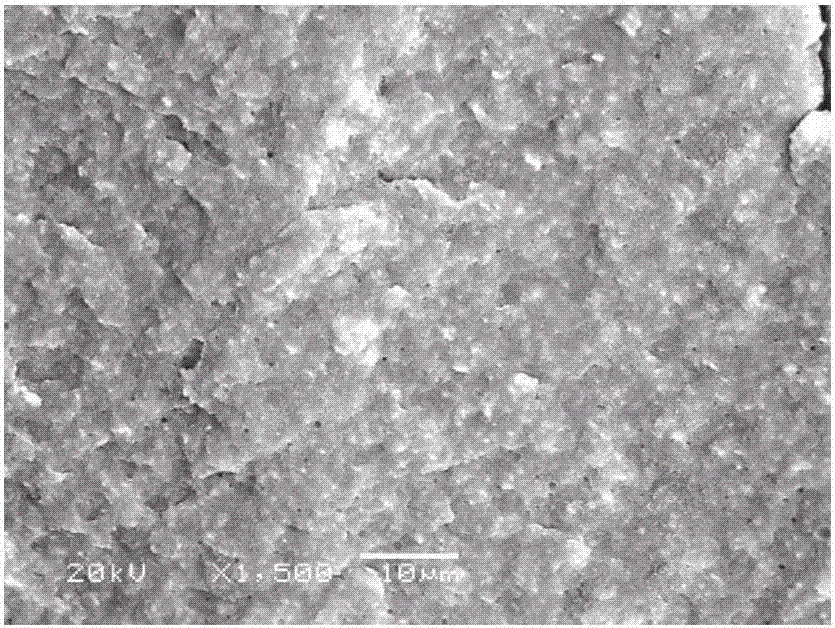

Image

Examples

Embodiment 1

[0055] The component parts by weight of the PA6 / MgO thermally conductive composite material of the present embodiment are as follows:

[0056]

[0057] The MgO filler includes MgO filler A and MgO filler B; the particle size of the MgO filler A is 1-10 μm; the MgO filler B is 30-50 μm; MgO filler A:B=1:4.

[0058] According to the above parts by weight, the PA6 / MgO heat-conducting composite material is obtained by modifying, mixing and granulating, which specifically includes the following steps:

[0059] Step (1): Modification:

[0060] Dilute the silane coupling agent by weight with ethanol to obtain a coupling agent solution, then add the compound magnesium oxide filler to the coupling agent solution, mix at 100°C for 30 minutes, take it out and place it in Dried in an oven at 120°C to constant weight to obtain a modified magnesium oxide filler;

[0061] Step (2): Mixing:

[0062] The prepared modified magnesia filler is mixed with the PA6 and antioxidant of said weig...

Embodiment 2

[0067] Compared with Example 1, the difference is that the components by weight of the PA6 / MgO thermally conductive composite material of this example are as follows:

[0068]

[0069] The MgO filler includes MgO filler A and MgO filler B; the particle size of the MgO filler A is 1-10 μm; the MgO filler B is 30-50 μm; MgO filler A:B=1:3.

[0070] According to the above parts by weight, modify, mix, and granulate to obtain the PA6 / MgO heat-conducting composite material. The thermal conductivity of the PA6 heat-conducting composite material obtained is 1.8923W / (m K), and the tensile strength is 91.52 MPa, impact strength 14.45kJ m -2 .

Embodiment 3

[0072] Compared with Example 1, the difference is that the components by weight of the PA6 / MgO thermally conductive composite material of this example are as follows:

[0073]

[0074]

[0075] The MgO filler includes MgO filler A and MgO filler B; the particle size of the MgO filler A is 1-10 μm; the MgO filler B is 30-50 μm; MgO filler A:B=1:2.

[0076] According to the above parts by weight, modify, mix, and granulate to obtain the PA6 / MgO heat-conducting composite material. The thermal conductivity of the PA6 heat-conducting composite material obtained is 1.7246W / (m K), and the tensile strength is 92.43 MPa, impact strength 14.00kJ m -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com