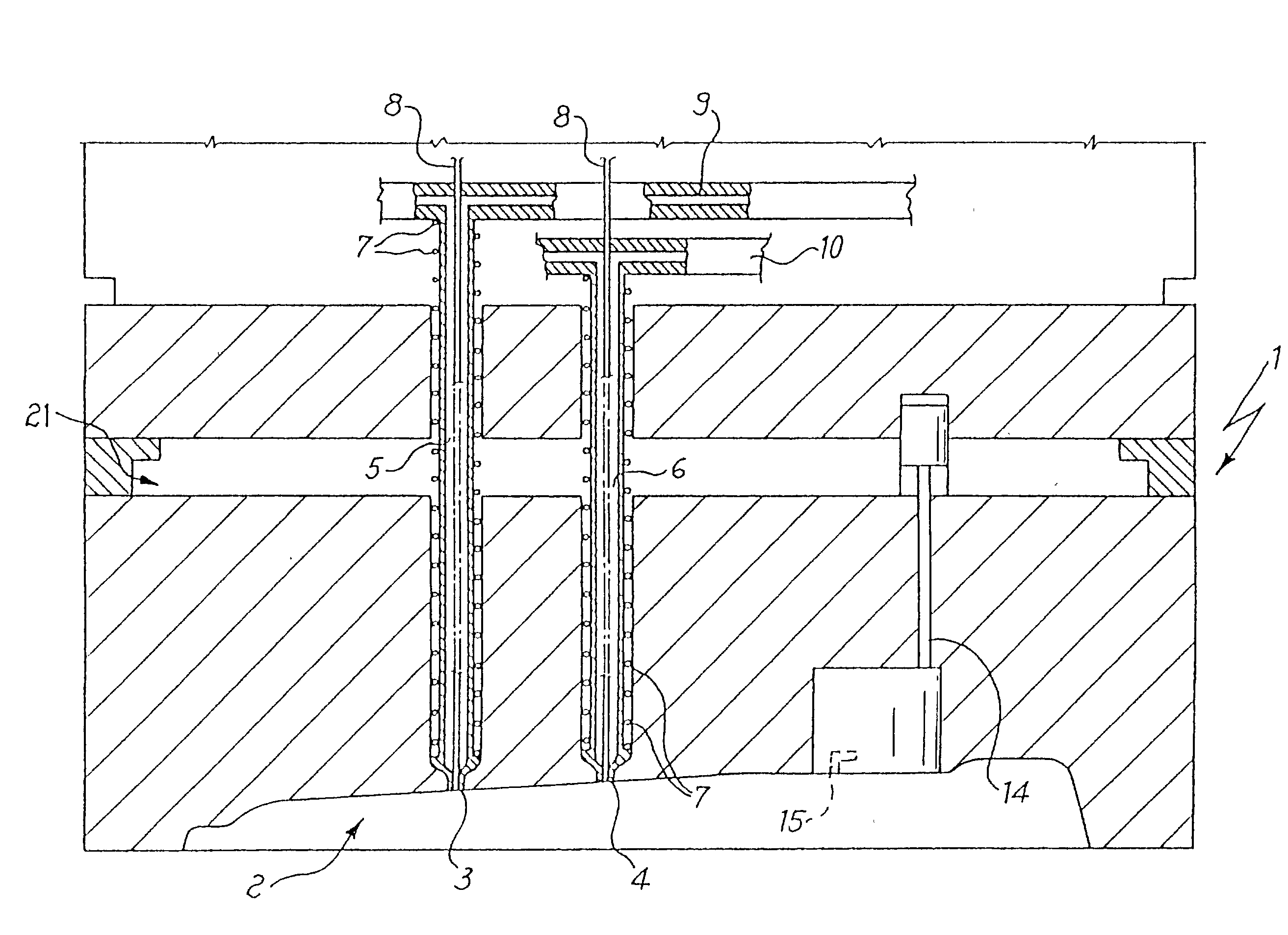

Process and device for coinjection molding multilayer products

a multi-layer, coinjection molding technology, applied in the field of coinjection molding multi-layer products, can solve the problems of flashing on the molding, high injection pressure, large presses, etc., and achieve the effect of simple and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

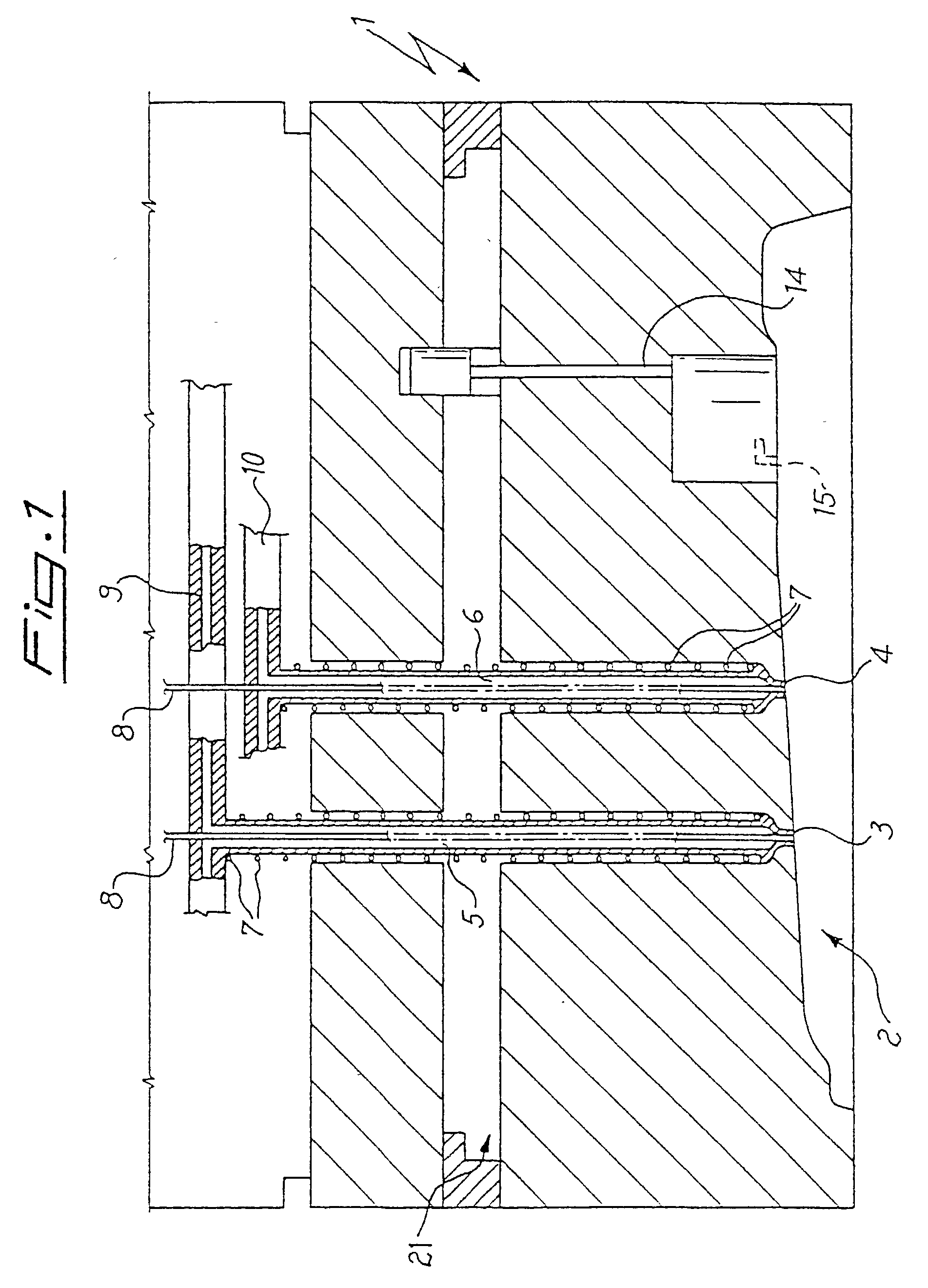

Method used

Image

Examples

example

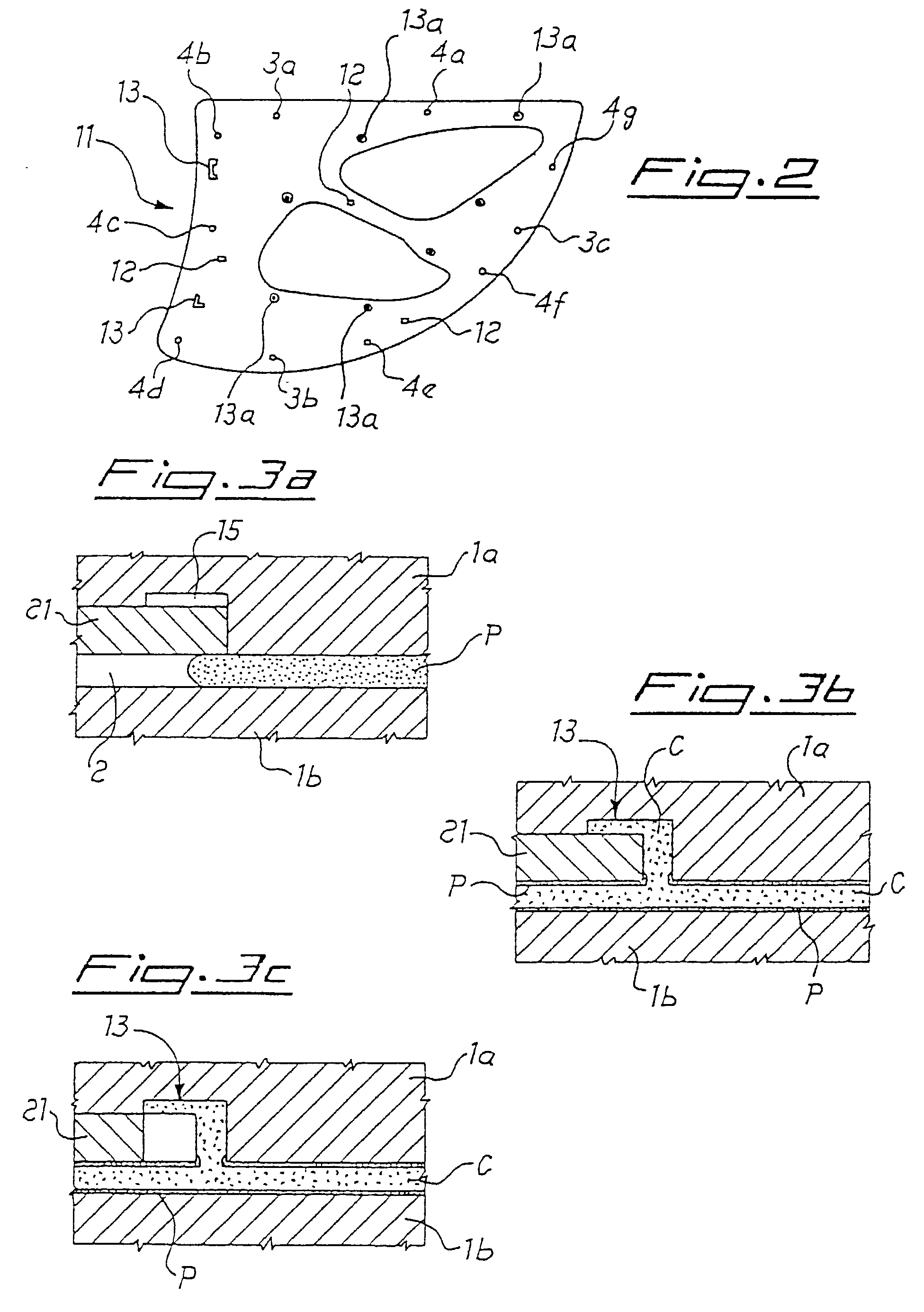

[0037] A door panel similar in shape and nozzle-distribution to that shown in FIG. 2 and described above, was produced using a twin-injector press. The skin material was a thermoplastic elastomer TPO based, type VSR 561 / 2 (MFI=5 at 230.degree. C.; 2.16 kg-ASTM 1238L) produced by REAP (Milano-Italy) and the core was polypropylene filled with wood flour type CR (MFI=5 a 190.degree. C.; 2.16 kg-ASTM 1238L) also produced by REAP. The skin to core ratio was about 50 / 50 (by weight) and the injection temperature was 220-230.degree. C. for the skin and 190.degree. C. for the core.

[0038] The injection times were controlled on the basis of the press screw travel to give the sequential injection described above. Retainers and studs were produced by using slide-valve techniques to obtain retaining elements that were comprised substantially of core material only. A door panel was produced with on external surface skin) distributed evenly over the entire surface except for the injection points an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com