Three-segment type block releasing technique for oil layer

A three-stage, plugging-removing technology, applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve problems such as short validity period, clogging of oil and water well reservoirs, unsatisfactory effect, etc., to reduce energy depleting, clogging-reducing, restoring or permeability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Formula 1: The first stage of strong penetrating swelling solution: 1% hydrogen peroxide + 0.2% 6501 + 0.05% chloroform + 0.2% sodium di-sec-octyl maleate + 98.55% water;

[0048] The second acid corrosion chelating solution: 3% hydrochloric acid + 1% acetic acid + 0.5% propynyl alcohol + 1.5% ammonium chloride + 0.5% hydrofluoric acid + 0.2% 6501 + 0.05% ethylenediaminetetraacetic acid (EDTA) + 93.25% water;

[0049] The third stage of extrusion protection solution: 0.6% dodecyl ammonium bromide quaternized polymer solution + 99.4% water.

[0050] The results of the permeability recovery experiment on the polymer-plugged artificial core are shown in Table 1:

[0051] Table 1 Core permeability and recovery rate table

[0052]

Core number

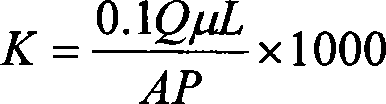

K 1

(×10 -3 μm 2 )

K 2

(×10 -3 μm 2 )

K 3

(×10 -3 μm 2 )

restore permeability

(%)

Increase penetration

K...

Embodiment 2

[0060] Formula 2: The first stage of strong penetrating swelling solution: 1% sodium perborate + 0.2% 6501 + 0.05% chloroform + 0.2% sodium di-sec-octyl maleate + 98.55% water;

[0061] The second acid corrosion chelating solution: 3% hydrochloric acid + 1% acetic acid + 0.5% propynyl alcohol + 1.5% ammonium chloride + 0.5% hydrofluoric acid + 0.2% 6501 + 0.05% ethylenediaminetetraacetic acid (EDTA) + 93.25% water;

[0062] The third stage of extrusion protection solution: 0.6% dodecyl ammonium bromide quaternized polymer solution + 99.4% water.

[0063] Table 3 shows the results of the permeability recovery experiment on the polymer-plugged artificial core.

[0064] Table 3 Core permeability and recovery rate table

[0065] Core number

K 1

(×10 -3 μm 2 )

K 2

(×10 -3 μm 2 )

K 3

(×10 -3 μm 2 )

restore permeability

(%)

Increase penetration

P...

Embodiment 3

[0070] Formula 3: The first stage of strong penetrating swelling solution: 1% hydrogen peroxide + 0.2% 6501 + 0.05% chloroform + 0.2% sodium di-sec-octyl maleate + 98.55% water;

[0071] The second acid corrosion chelating solution: 10% hydrochloric acid + 1% acetic acid + 0.5% propynyl alcohol + 1.5% ammonium chloride + 4% hydrofluoric acid + 0.2% 6501 + 0.05% ethylenediaminetetraacetic acid (EDTA) + 82.75% water;

[0072] The third stage of extrusion protection solution: 0.6% dodecyl ammonium bromide quaternized polymer solution + 99.4% water.

[0073] See Table 5 for the results of the permeability change experiment of Hailaer low-permeability cores before and after treatment.

[0074] Table 5 Permeability change table before and after treatment

[0075] Core No.

[0076] It can be seen from the above table that this patented technology can effectively improve the permeability of low-permeability Hailaer Oilfield, that is, this patent is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com