Three-segment type block releasing technique for oil layer

A three-stage, plugging-removing technology, which is applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problems of oil-water well reservoir clogging, unsatisfactory effect, short validity period, etc., to slow down clogging , restore or increase permeability, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

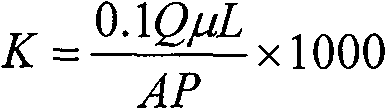

Method used

Image

Examples

Embodiment 1

[0046] Formula 1: The first stage of strong penetration swelling liquid: 1% hydrogen peroxide + 0.2% 6501 + 0.05% chloroform + 0.2% sodium di-sec-octyl maleate + 98.55% water;

[0047] The second stage of acid erosion chelating liquid: 3% hydrochloric acid + 1% acetic acid + 0.5% propynol + 1.5% ammonium chloride + 0.5% hydrofluoric acid + 0.2% 6501 + 0.05% ethylenediaminetetraacetic acid (EDTA)+ 93.25% water;

[0048] The third stage squeeze protection solution: 0.6% diddecadimethylammonium bromide quaternized polymer solution + 99.4% water.

[0049] The results of the permeability recovery experiment of the artificial core plugged by polymer are shown in Table 1:

[0050] Table 1 Core permeability and recovery rate table

[0051]

Core number

K 1

(×10 -3 μm 2 )

K 2

(×10 -3 μm 2 )

K 3

(×10 -3 μm 2 )

Recovery permeability

(%)

Increase penetration

K 3 / K 2

2-1

56

12

49

87.5

4.08

2-2

54

10.9

41

76

3.76

2-3

55

11.2

46

83.6

4.1

[0052]...

Embodiment 2

[0059] Formulation 2: The first stage of strong penetration swelling liquid: 1% sodium perborate + 0.2% 6501 + 0.05% chloroform + 0.2% sodium di-secondary octyl sulfonate maleate + 98.55% water;

[0060] The second stage of acid erosion chelating liquid: 3% hydrochloric acid + 1% acetic acid + 0.5% propynol + 1.5% ammonium chloride + 0.5% hydrofluoric acid + 0.2% 6501 + 0.05% ethylenediaminetetraacetic acid (EDTA)+ 93.25% water;

[0061] The third stage squeeze protection solution: 0.6% diddecadimethylammonium bromide quaternized polymer solution + 99.4% water.

[0062] Table 3 shows the results of the permeability recovery experiment of the polymer plugged artificial core.

[0063] Table 3 Core permeability and recovery rate table

[0064]

Core number

K 1

(×10 -3 μm 2 )

K 2

(×10 -3 μm 2 )

K 3

(×10 -3 μm 2 )

Recovery permeability

(%)

Increase penetration

K 3 / K 2

[0065] 3-1

66

10.5

58.4

88.5

4.08

3-2

64

9.8

51.3

80.2

3.76

[0066] Se...

Embodiment 3

[0070] Formula 3: The first stage of strong penetration swelling liquid: 1% hydrogen peroxide + 0.2% 6501 + 0.05% chloroform + 0.2% sodium di-sec-octyl sulfonate + 98.55% water;

[0071] The second stage of acid erosion chelating solution: 10% hydrochloric acid + 1% acetic acid + 0.5% propynol + 1.5% ammonium chloride + 4% hydrofluoric acid + 0.2% 6501 + 0.05% ethylenediaminetetraacetic acid (EDTA)+ 82.75% water;

[0072] The third stage squeeze protection solution: 0.6% diddecadimethylammonium bromide quaternized polymer solution + 99.4% water.

[0073] The results of the permeability change experiment before and after the treatment of the Hailar low permeability core are shown in Table 5.

[0074] Table 5 Permeability changes before and after treatment

[0075] Core Number

[0076] It can be seen from the above table that the patented technology can effectively improve the permeability of the low-permeability Hailar oil field, that is, the patent is also applicable to low-permeabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com