A microwave heating removal method for coal seam water lock damage in surface coalbed methane extraction drilling

A technology for water lock damage and coalbed methane, which is applied in the fields of mining fluids, mining equipment, earthwork drilling, etc. Less water lock damage and other problems, to achieve the effect of restoring or improving gas permeability, restoring or desorption and permeability, and low work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

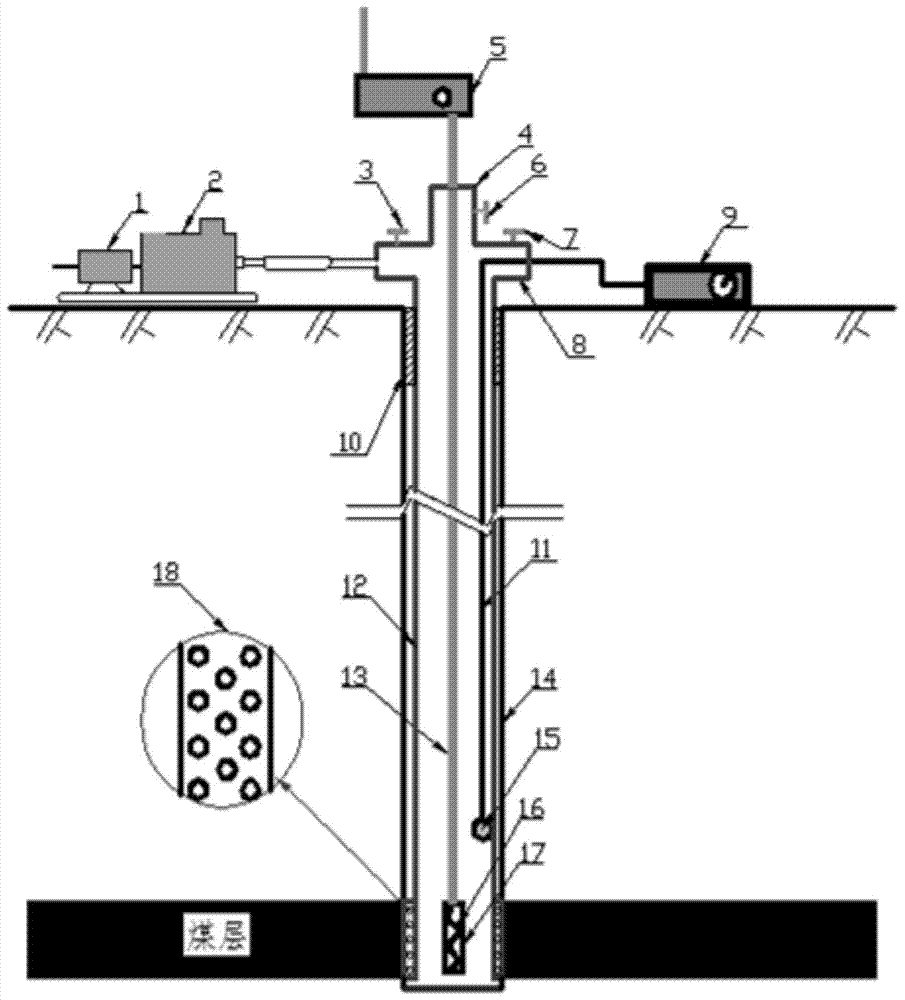

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] A microwave heating removal method for coal seam water lock damage in surface coalbed methane extraction drilling first arranges a microwave transmitter on the ground near the coalbed methane extraction drilling, and then guides the microwaves generated on the ground into the ground gas extraction drilling through a waveguide; Set a microwave radiation port containing a microwave helical antenna at the position of the target coal seam damaged by water lock, and use the electromagnetic radiation effect of the microwave field on the coal medium containing two-phase fluids such as gas and water in the target coal seam to make the inside and outside of the near wellbore coal seam The medium is heated at the same time to promote the evaporation of water in the gas-containing coal seam damaged by water lock, reduce the water saturation of the coal seam, increase the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com