Method for compensating thermal energy of horizontal well mining heavy oil reservoirs in large power and subsection mode in pit

A heavy oil reservoir, high-power technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of loss, poor thermal recovery effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

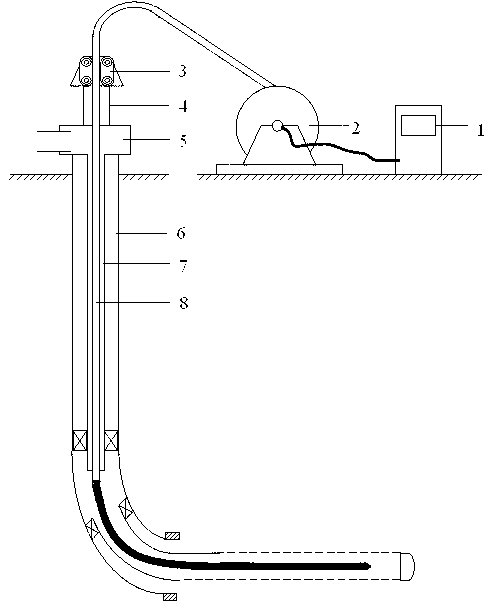

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] A method for compensating heat energy in sections with high power downhole in heavy oil reservoirs produced by horizontal wells according to the present invention is composed of an oil well string and an electric heater system. The oil well string consists of a wellhead device (5), casing (6), oil (7), composed of horizontal section screen and packer, the horizontal section screen of the oil well string is drilled into a certain length of wellbore along the horizontal direction of the oil layer, and communicated with the ground through the casing (6), and is controlled by the wellhead device (5) Control, the oil pipe (7) is located in the casing (6), extending to the top of the oil layer or the root of the screen in the horizontal section, and the upper part of the oil pipe (7) is connected to the wellhead device (5) to form a steam injection pipeline.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com