Thickened oil steam production synergist and its preparing method

A technology of synergist and steam, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of many construction steps, long cycle, high investment, and achieve peak oil production, short cycle, The effect of improving oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

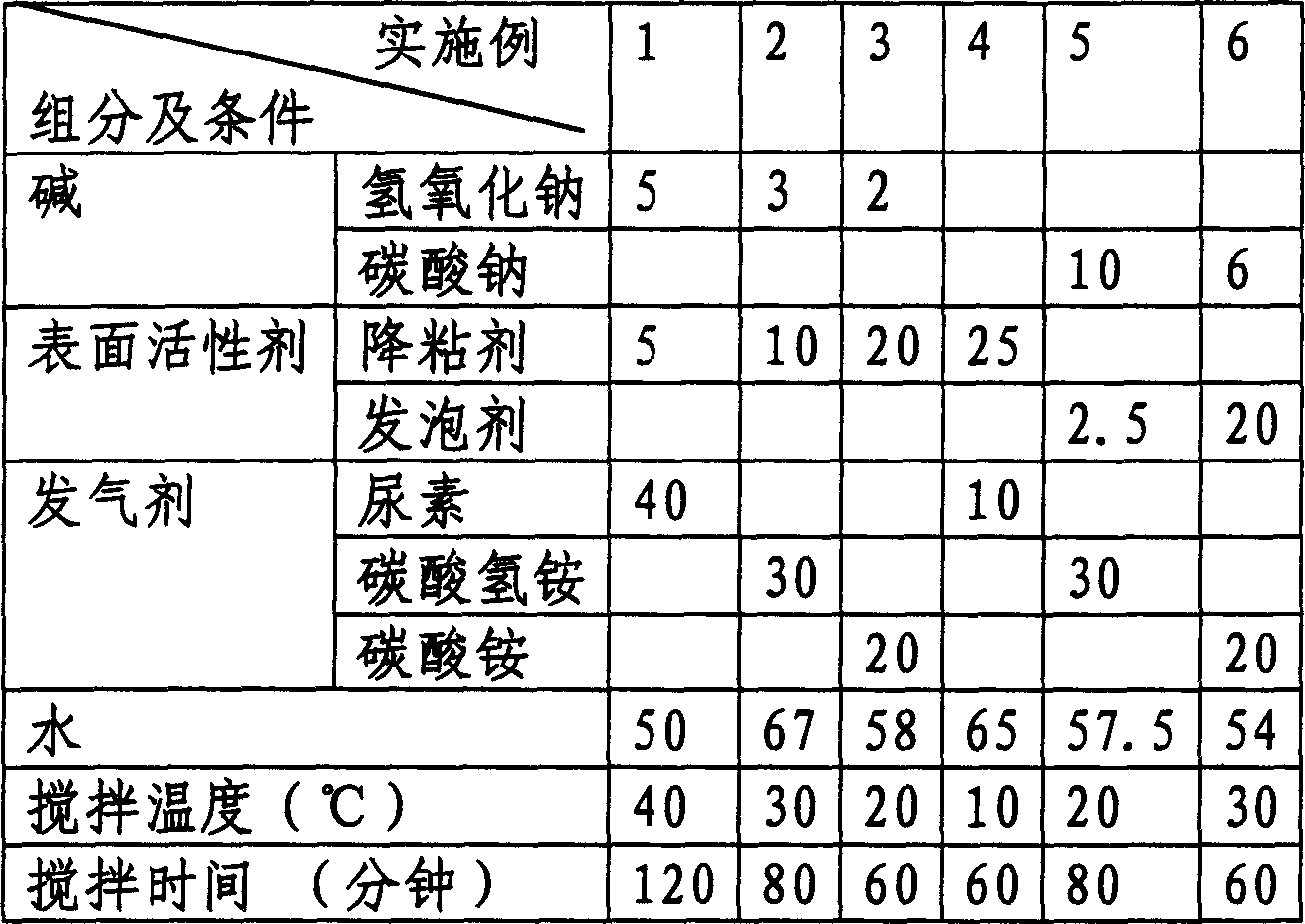

[0023] The components and configuration conditions of each embodiment of synergist 1-6 of the present invention are as follows:

[0024]

[0025] The present invention uses ammonium carbonate, ammonium bicarbonate, urea, sodium oxide, and sodium carbonate to adopt commercially available products, and its industrial grade purity is above 95%. The surfactant used in the present invention can be alkali lignosulfonate, phenolic polyether viscosity reducer, preferably alkali lignosulfonate. Such as SEPA-1, WPS-3, GL-1, KW-1 and BK-1, etc. Surfactant also can use petroleum sulfonate or alcohol ether sulfate foaming agent, preferably alcohol ether sulfate. Such as LAS, TAS, SS02, HR9801, SD1020, etc.

[0026] In the present invention, alkali, high-temperature surfactant and gas-generating agent are added into a certain amount of water in the order of stirring and dissolving to form a homogeneous solution. Dissolve the alkali in a certain amount of water first, raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com