Method of predicting steam huff-puff early productivity of heavy oil reservoir horizontal well

A heavy oil reservoir and productivity prediction technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., can solve problems such as cumbersome, time-consuming, complex action mechanism and reservoir seepage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

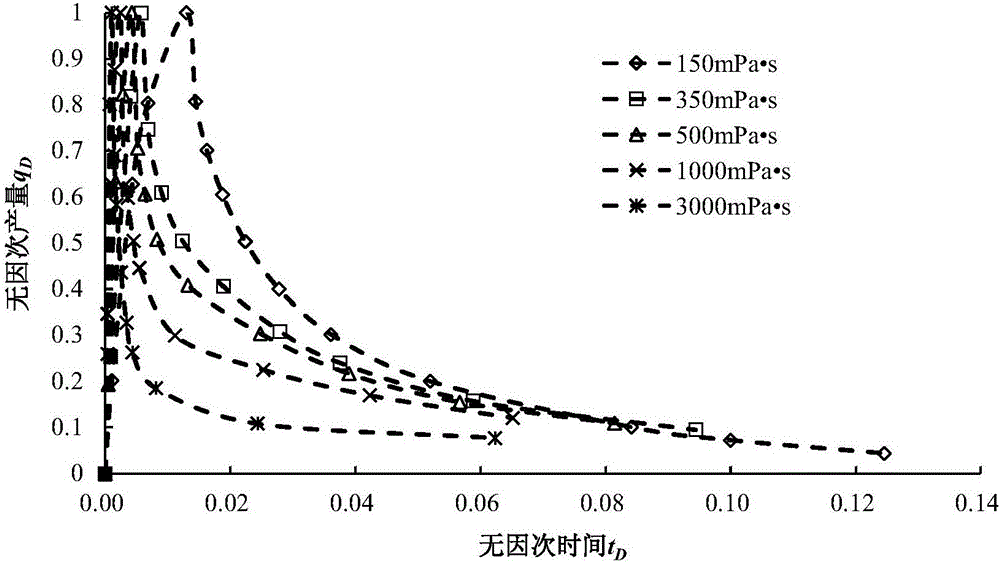

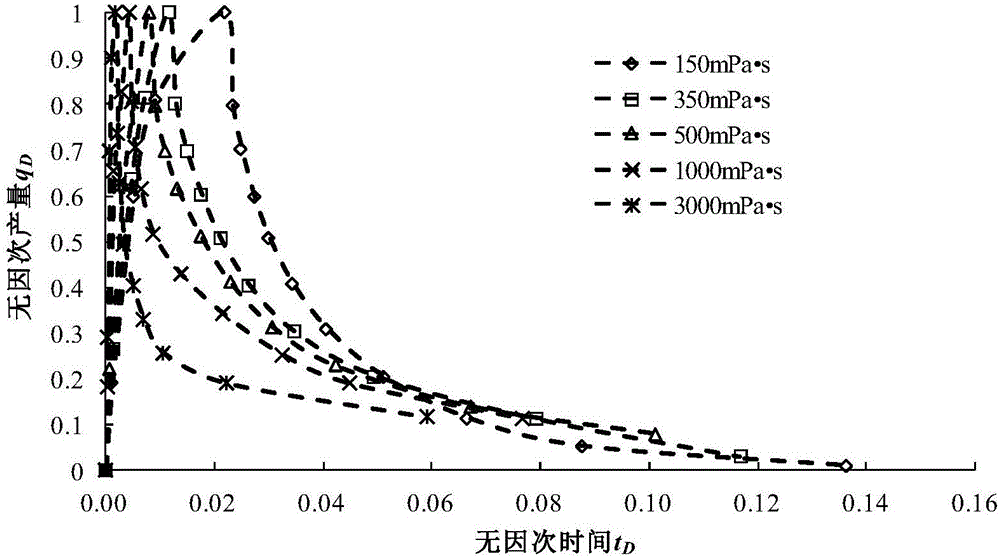

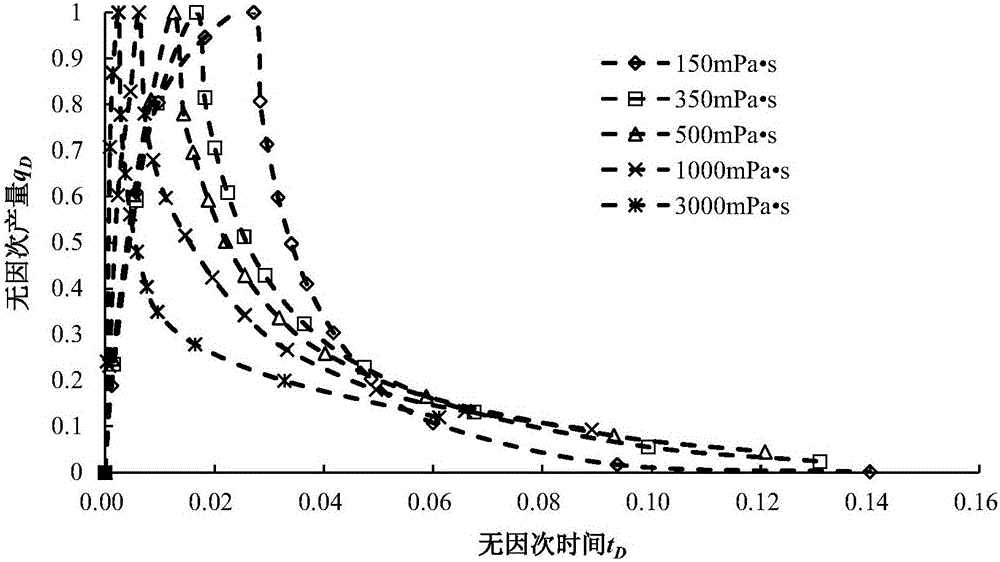

[0064] The present invention provides a method for predicting initial productivity of steam huff and puff of a horizontal well in a heavy oil reservoir, comprising the following steps:

[0065] 1) Based on the seepage theory, a mathematical model of thermal oil recovery for heavy oil reservoirs is established. The specific process is as follows:

[0066] ① The basic assumptions for determining the thermal recovery mathematical model of heavy oil reservoirs are as follows:

[0067] a. There are three phases of oil, gas and water in heavy oil reservoirs, with a total of n c species (n c - 1 hydrocarbon component and a water component) chemical components, any component obeys the principle of phase equilibrium in the phase distribution relationship;

[0068] b. The flow satisfies Darcy's law, and there is no chemical reaction between the chemical comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com