A microchannel near-isothermal compression transcritical carbon dioxide circulation system and method

A technology of isothermal compression and carbon dioxide, applied in compressors, compressors, fluid circulation arrangements, etc., can solve problems such as poor coefficient of performance, achieve the effect of reducing power consumption and improving theoretical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

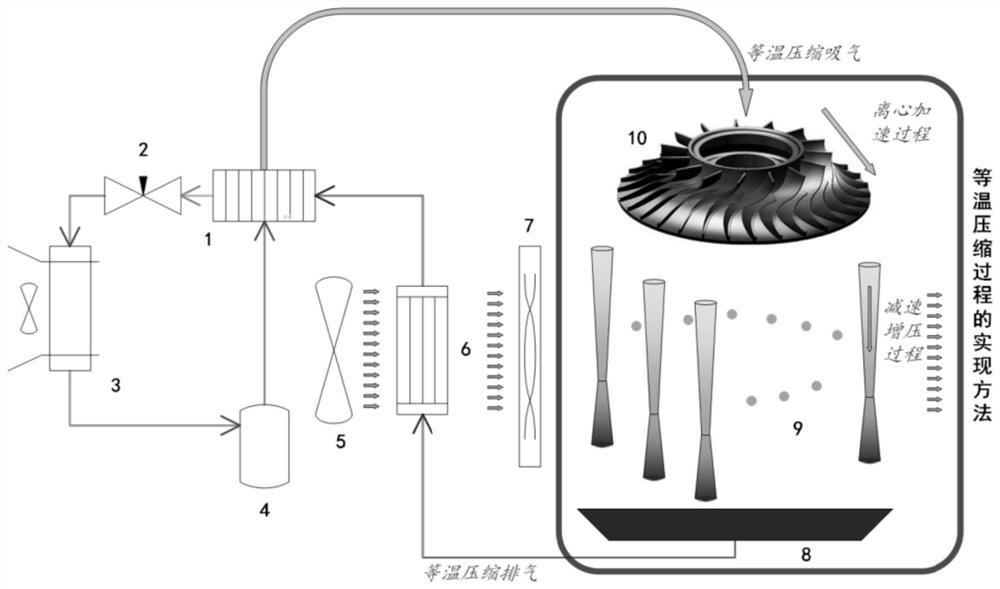

[0027] see figure 1 As shown, a microchannel near-isothermal compression transcritical carbon dioxide circulation system of the present invention includes: regenerator 1, electronic expansion valve 2, evaporator 3, gas-liquid separator 4, axial flow fan 5, auxiliary gas cooler 6. Air valve 7, gas collector 8, scaling microchannel heat exchanger 9 and centrifugal impeller 10.

[0028] In the present invention, the low-pressure outlet of the regenerator 1 is connected to the central inlet of the centrifugal impeller 10 through an isothermal compression suction pipe, and the circumferential outlet of the centrifugal impeller 10 is connected to the inlets of several zoom-type microchannel heat exchangers 9. The outlet of the heater 9 is connected to the inlet of the gas collector 8, the outlet of the gas collector 8 is connected to the inlet of the auxiliary gas cooler 6 through an isothermal compression exhaust pipe, and the outlet of the auxiliary gas cooler 6 is connected to th...

Embodiment 2

[0030] In the circulation system of the present invention, the evaporator 3 has its own axial flow fan, and the air passage driven by the axial flow fan of the evaporator is the gap between the finned tubes of the evaporator 3, and the auxiliary gas cooler 6 and the scaling in the isothermal compressor The micro-channel heat exchanger 9 is equipped with an axial flow fan 5, the air channel in the auxiliary gas cooler 6 is the gap between the finned tubes, and the air channel in the zoom-type micro-channel heat exchanger 9 is the gap between the micro-channel fins The air duct passes through the air valve 7 between the inner air duct of the auxiliary gas cooler 6 and the inner air duct of the zoom-type micro-channel heat exchanger 9 ; .

Embodiment 3

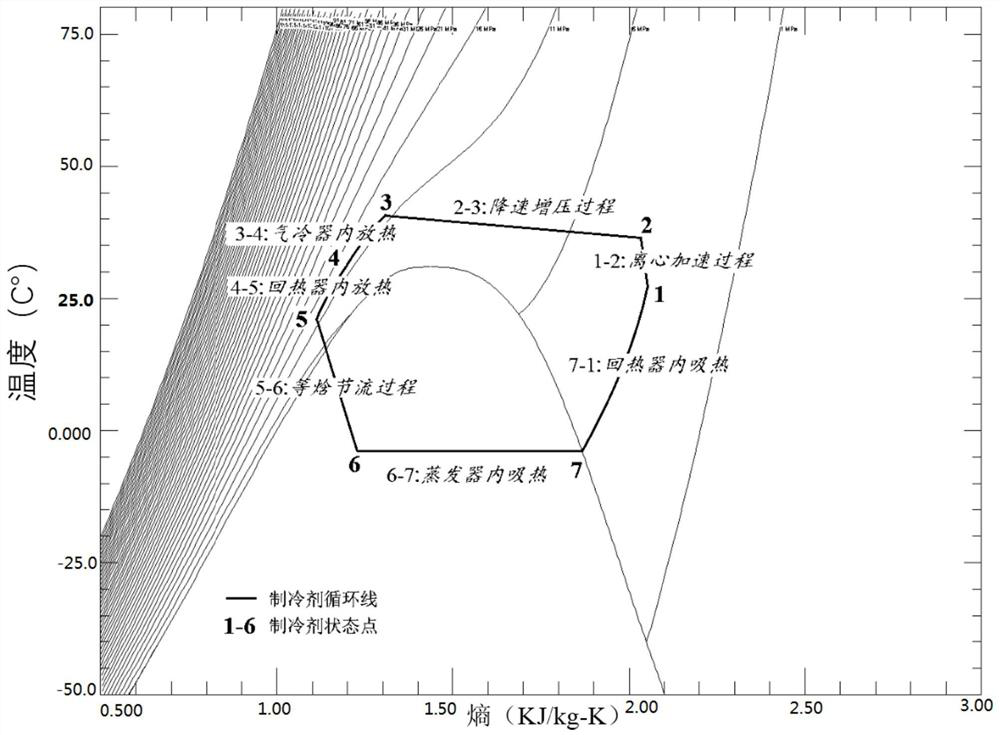

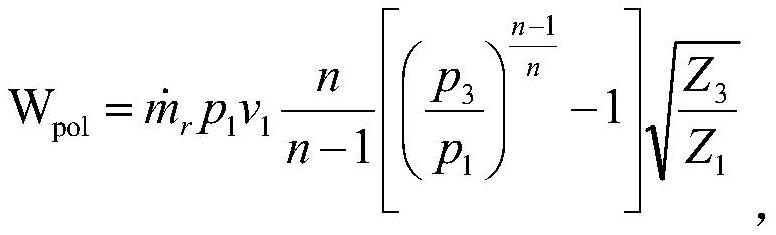

[0032] In the circulation system of the present invention, the low-pressure CO 2 After the gas enters the isothermal compressor through the isothermal compression suction pipe, it is first accelerated to a supersonic state by the centrifugal impeller 10, see figure 2 From state 1 to state 2, it enters the scaled microchannel heat exchanger 9 to realize the process of deceleration, pressurization, and rapid heat release, and converts kinetic energy into pressure energy in the form of near-isothermal compression, see figure 2 Middle state 2 to state 3.

[0033]A microchannel near-isothermal compression type transcritical carbon dioxide circulation method of the present invention, because there is a heat exchange temperature difference in the scaling microchannel heat exchanger 9 in practical application, the CO in the pipe cannot be 2 The gas cools to room temperature, so this pressurization process can only be considered a near-isothermal compression process. Subsequently, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com