In situ combustion slug and steam driving combined type crude oil producing method

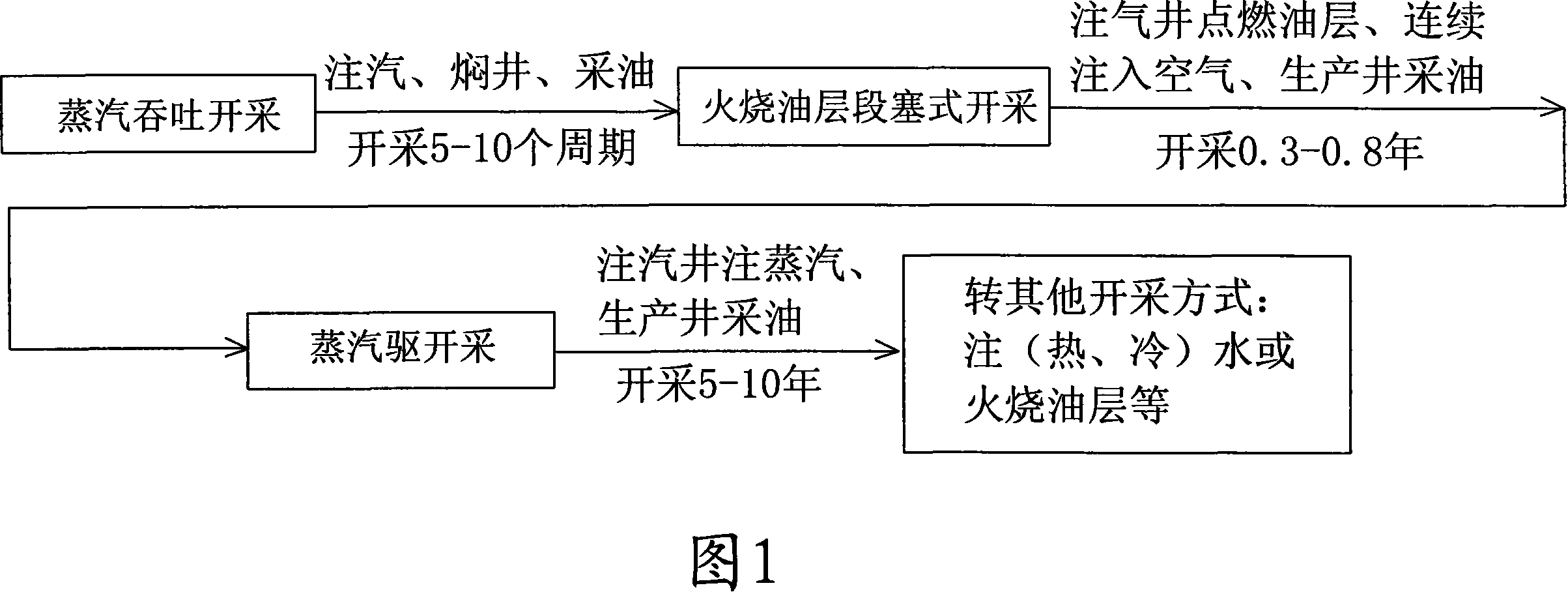

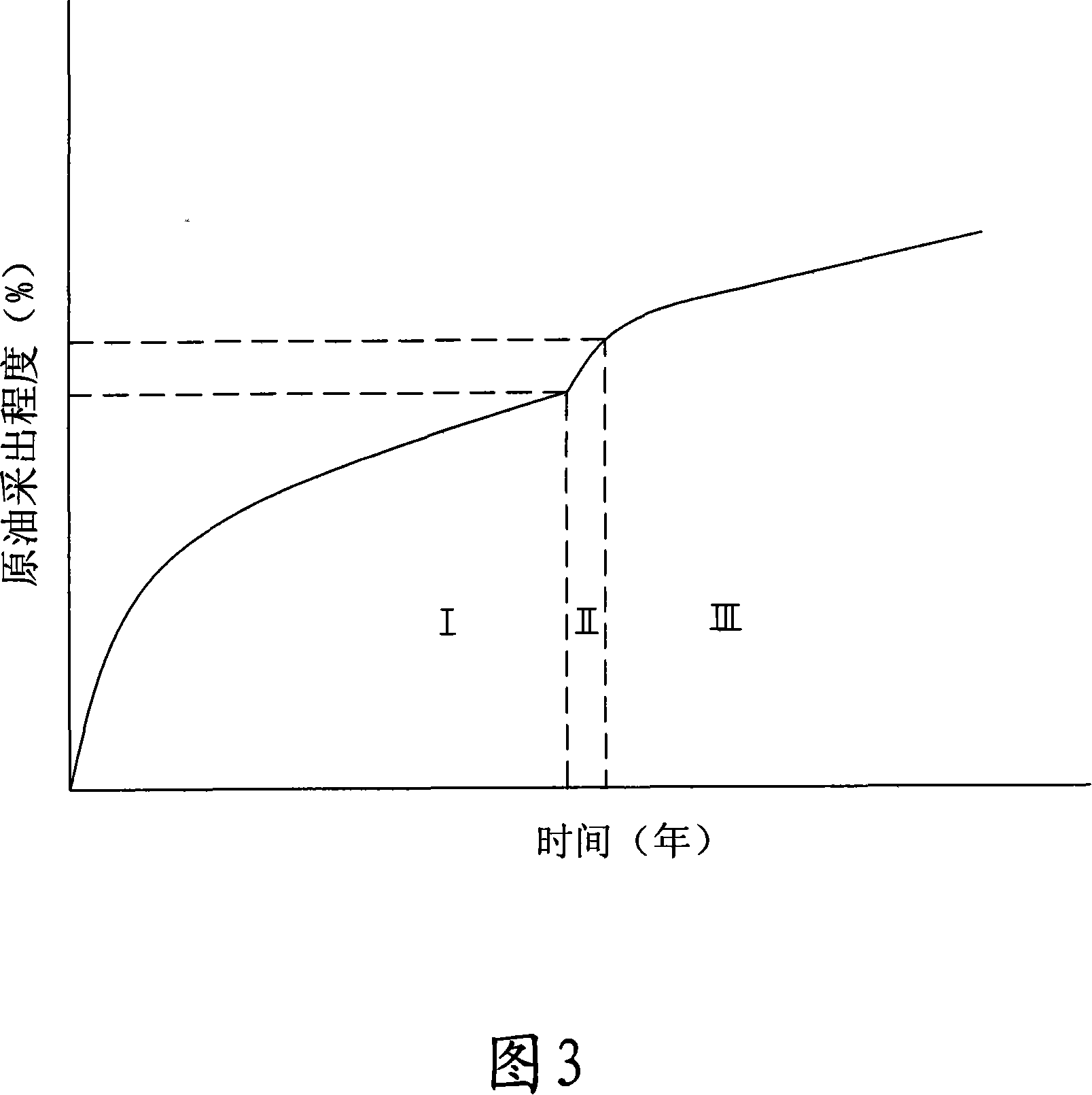

A technology of burning oil layers and steam flooding, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of low oil recovery rate and large water storage in a single well, so as to save investment costs and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The buried depth of oilfield 1 is 600-1000m, the effective thickness of oil layer is 20.0m, the ratio of net to total thickness is 0.5, the average porosity is 25%, the average permeability is 500md, the coefficient of variation of permeability is 0.8, and the viscosity of crude oil under oil layer conditions is 120mPa .s.

[0039] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.50, total reservoir thickness>10.0m, net-to-total thickness ratio>0.5, reservoir porosity>0.2, permeability variation coefficient200md , the viscosity of crude oil under oil layer conditions <20000mPa.s;

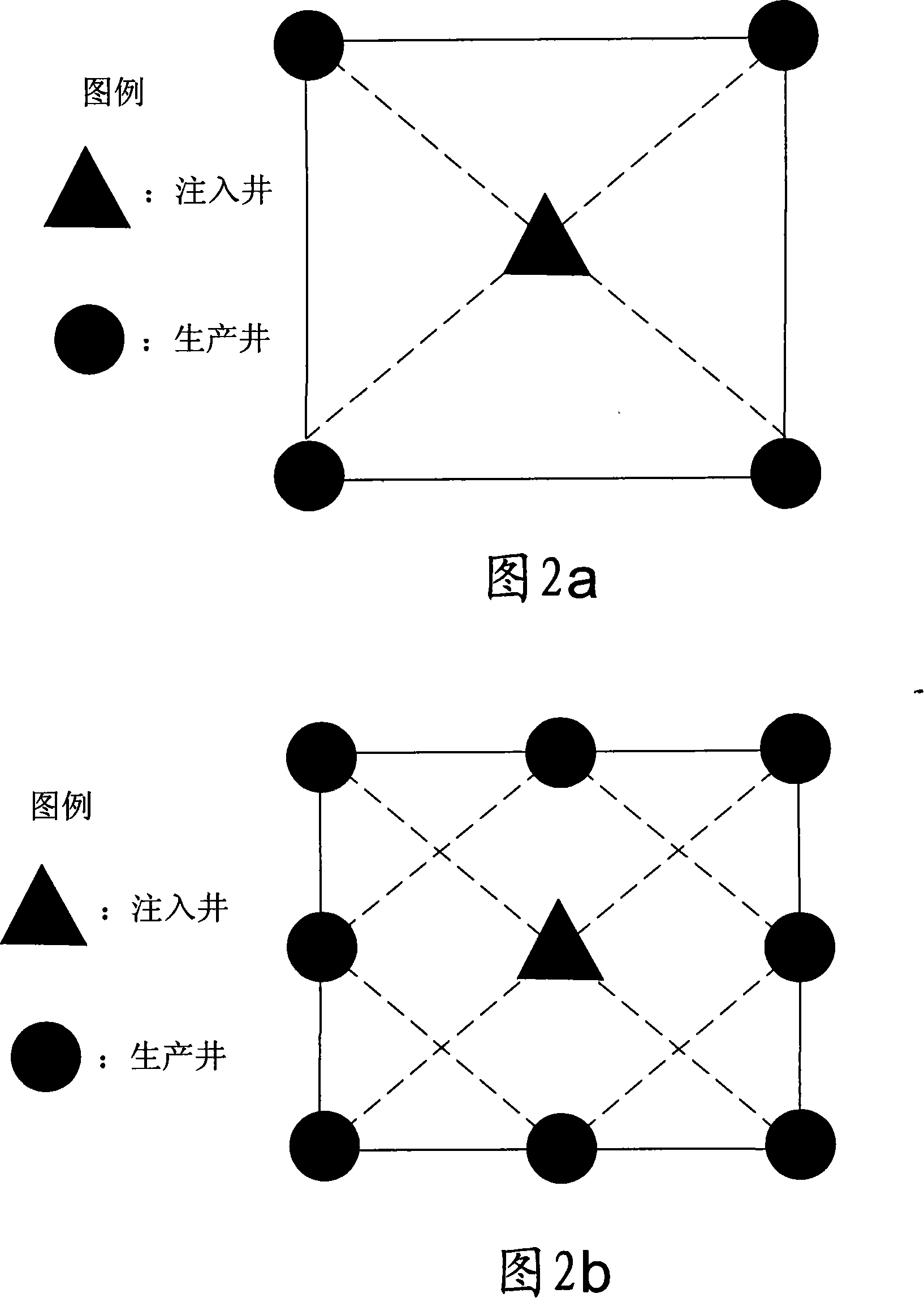

[0040] 2) First, the steam huff and puff is used to exploit the oil reservoir. The well pattern is a square well pattern, the well spacing can be 150m, and the steam is injected into the well continuously according to the steam injection intensity of 100t / m. , cont...

Embodiment 2

[0044] The buried depth of oil field 2 is 1500-1600m, the effective thickness of the oil layer is 60.0m, the net total thickness ratio is 0.8, the average porosity is 25%, the average permeability is 1200md, and the viscosity of crude oil under the oil layer conditions is 510mPa.s.

[0045] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.50, total reservoir thickness>10.0m, net-to-total thickness ratio>0.5, reservoir porosity>0.2, permeability variation coefficient200md , the viscosity of crude oil under oil layer conditions <20000mPa.s;

[0046] 2) Firstly, the steam huff and puff is used to exploit the oil reservoir. The well pattern is a square well pattern, and the well spacing can be 105m. The steam is continuously injected into the well according to the steam injection intensity of 100t / m. After the well is soaked for 7 days, the heat can be di...

Embodiment 3

[0050] The buried depth of the oil reservoir in oil field 3 is 1000-1500m, the effective thickness of the oil layer is 40.0m, the net total thickness ratio is 0.46, the average porosity is 23%, the average permeability is 400md, the coefficient of variation of permeability is 0.7, and the viscosity of crude oil under the oil layer condition is 2000mPa .s.

[0051] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.50, total reservoir thickness>10.0m, net-to-total thickness ratio>0.5, reservoir porosity>0.2, permeability variation coefficient200md , Crude oil viscosity under oil reservoir conditions <10000mPa.s;

[0052] 2) First, the steam huff and puff is used to exploit the oil reservoir. The well pattern is a square well pattern, and the well spacing can be 120m. The steam is continuously injected into the well according to the steam injection inten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com