Method for integrally catalyzing, reforming, reducing viscosity, extracting and transporting thick oil

A catalytic upgrading and heavy oil technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of reducing the density of heavy oil, reducing the quality of thin oil, heat conduction loss, etc., to weaken the interaction force , Saving thin oil resources and improving the quality of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

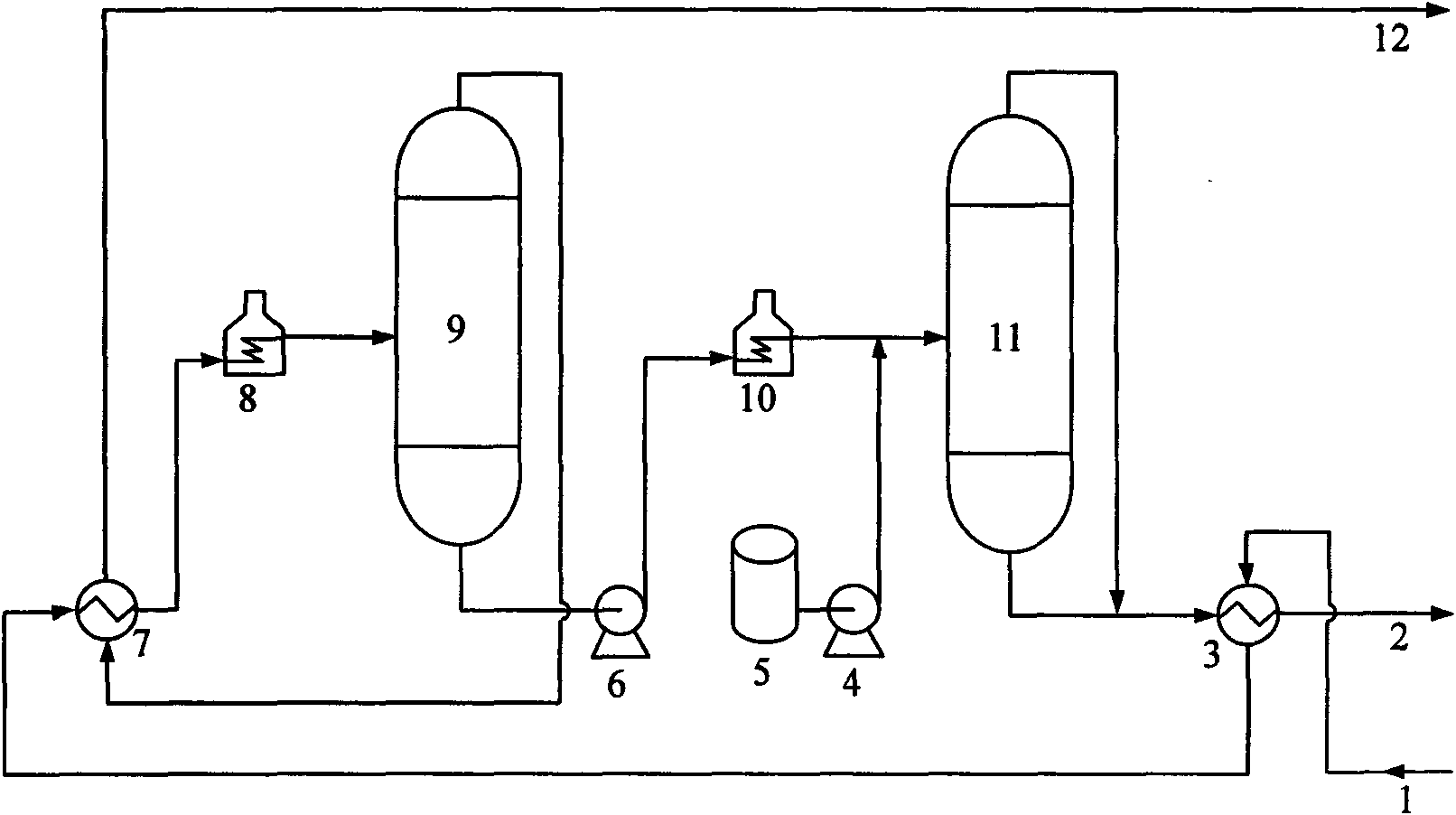

[0014] According to the mass ratio of thin oil to heavy oil of 0.40, condensate oil and heavy oil with a viscosity of 9084mPa·s at 50°C are fully stirred and mixed in the wellbore, so that the viscosity of the heavy oil meets the requirements of production and well station pipeline transportation. Oil (with a viscosity of 126mPa·s) is delivered to the catalytic reforming device through pipelines. Thin heavy oil is heated to a certain temperature through the heat exchangers 3 and 7, and then heated to 350°C by the heating furnace 8. The distillate oil before 350°C is evaporated in the distillation tower 9, and then cooled to 60°C by the heat exchanger 7. Below ℃, inject the thin oil into the wellbore through the wellbore thin oil input pipe 12 and use it for circulation and dilution. After 350°C, the distillate oil is decatalytically upgraded. The distillate after 350°C is heated to 370°C through the heating furnace 10, mixed with the ferric oleate catalyst (0.05 wt%) pumped f...

Embodiment 2

[0016] According to the mass ratio of thin oil to heavy oil of 0.50, light hydrocarbons in the oil field and heavy oil with a viscosity of 13210mPa·s at 50°C were fully stirred and mixed in the wellbore to make the viscosity of the heavy oil meet the requirements of production and well station pipeline transportation. Oil (with a viscosity of 124mPa·s) is delivered to the catalytic reforming device through pipelines. According to the method described in Example 1, the mixed heavy oil was catalytically upgraded by adding catalyst nickel oleate (amount of 0.06 wt%) at 380°C for 40 minutes. The measured viscosity of the modified heavy oil is 165mPa·s, and the viscosity reduction rate of the modified heavy oil is 98.75%.

Embodiment 3

[0018] According to the mass ratio of thin oil to heavy oil of 0.60, straight-run gasoline and heavy oil with a viscosity of 17460mPa·s at 50°C were fully stirred and mixed in the wellbore, so that the viscosity of the heavy oil could meet the requirements of production and pipeline transportation in the well station, and the mixed thin thick oil was obtained. Oil (with a viscosity of 78mPa·s) is delivered to the catalytic reforming device through pipelines. According to the method described in Example 1, a catalyst copper oleate (amount of 0.07wt%) was added for catalytic upgrading at 390° C. for 50 minutes. The measured viscosity of the modified heavy oil is 297mPa·s, and the viscosity reduction rate of the modified heavy oil is 98.30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com