Viscosity-reducing oil displacement agent and oil displacement system for heavy oil reservoirs

A viscous oil displacement agent technology for heavy oil reservoirs, applied in the direction of production fluid, drilling composition, wellbore/well components, etc., can solve problems such as difficult to reach, poor oil displacement effect, high oil displacement efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment.

[0034] The instruments, reagents, materials, etc. involved in the following examples, unless otherwise specified, are conventional instruments, reagents, materials, etc. in the prior art, and can be obtained through formal commercial channels. The experimental methods, detection methods, etc. involved in the following examples, unless otherwise specified, are conventional experimental methods, detection methods, etc. in the prior art.

[0035] Embodiment Viscosity-reducing oil displacement agent and its application

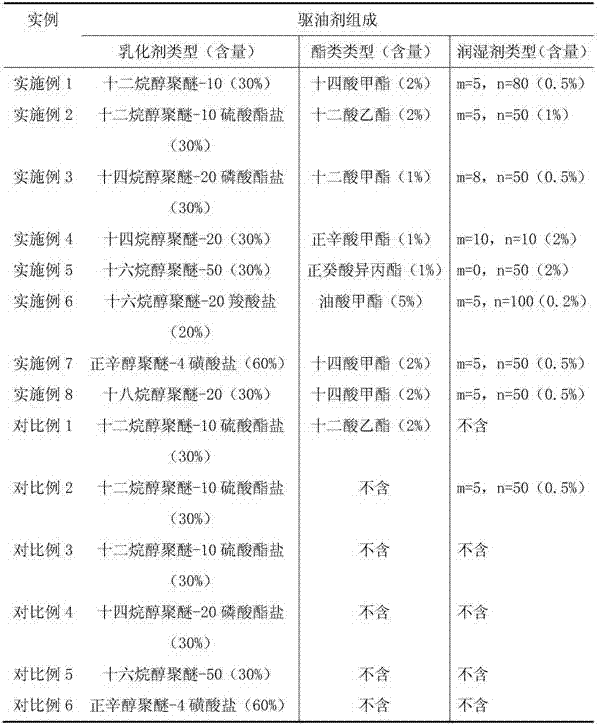

[0036] Mix emulsifier, ester compound, wetting agent and water in a certain proportion to prepare viscosity reducing oil displacement agent.

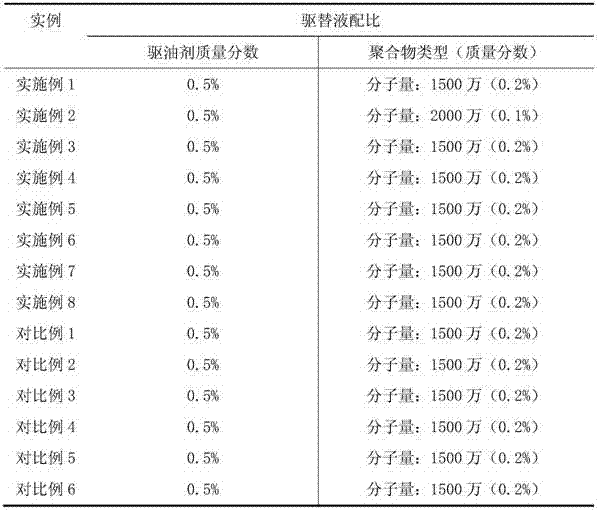

[0037] The viscosity reducing oil displacement agent, polymer and water are mixed in a certain proportion to prepare a displacement fluid (viscosity reducing oil displacement agent-polymer system).

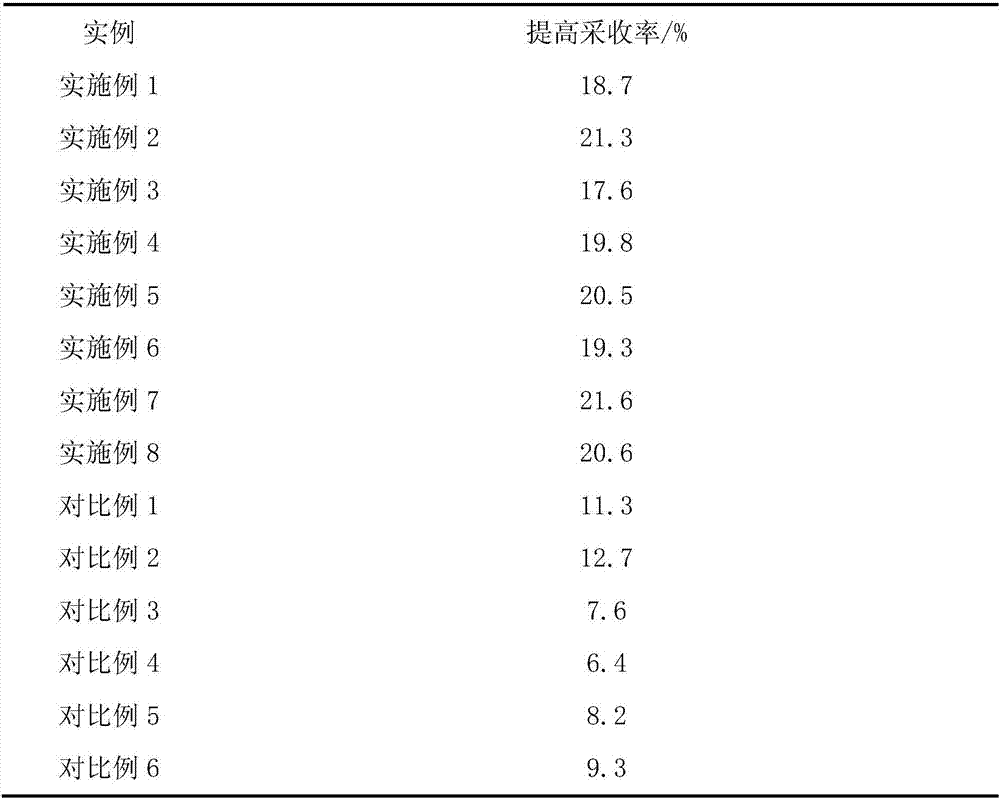

[0038] See Table 1 for the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com