Gravity and steam flooding combined mining method of thick layer containing interlayer common heavy oil reservoir

A technology for heavy oil reservoirs and combined production, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., and can solve the problems of unproducible oil layers in the upper part of the interlayer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

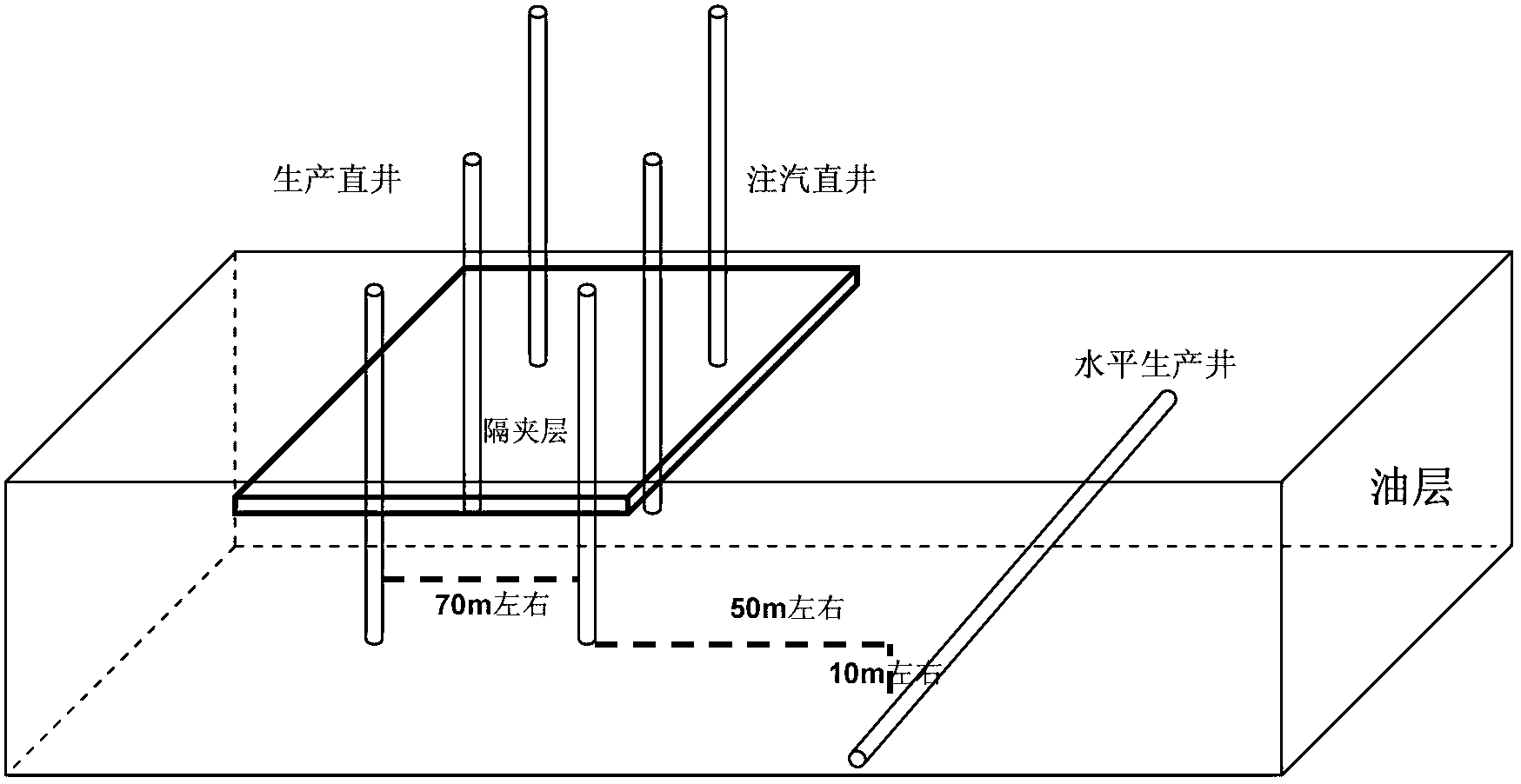

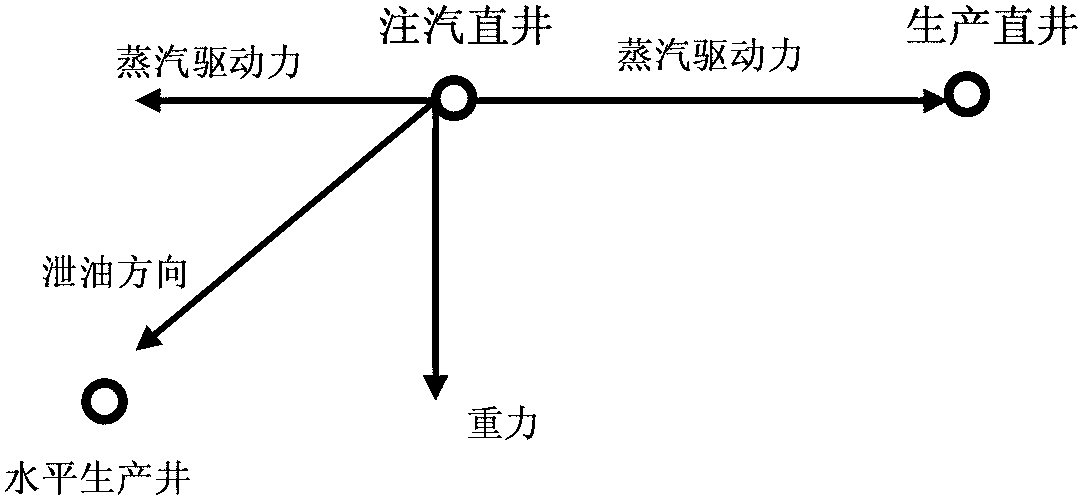

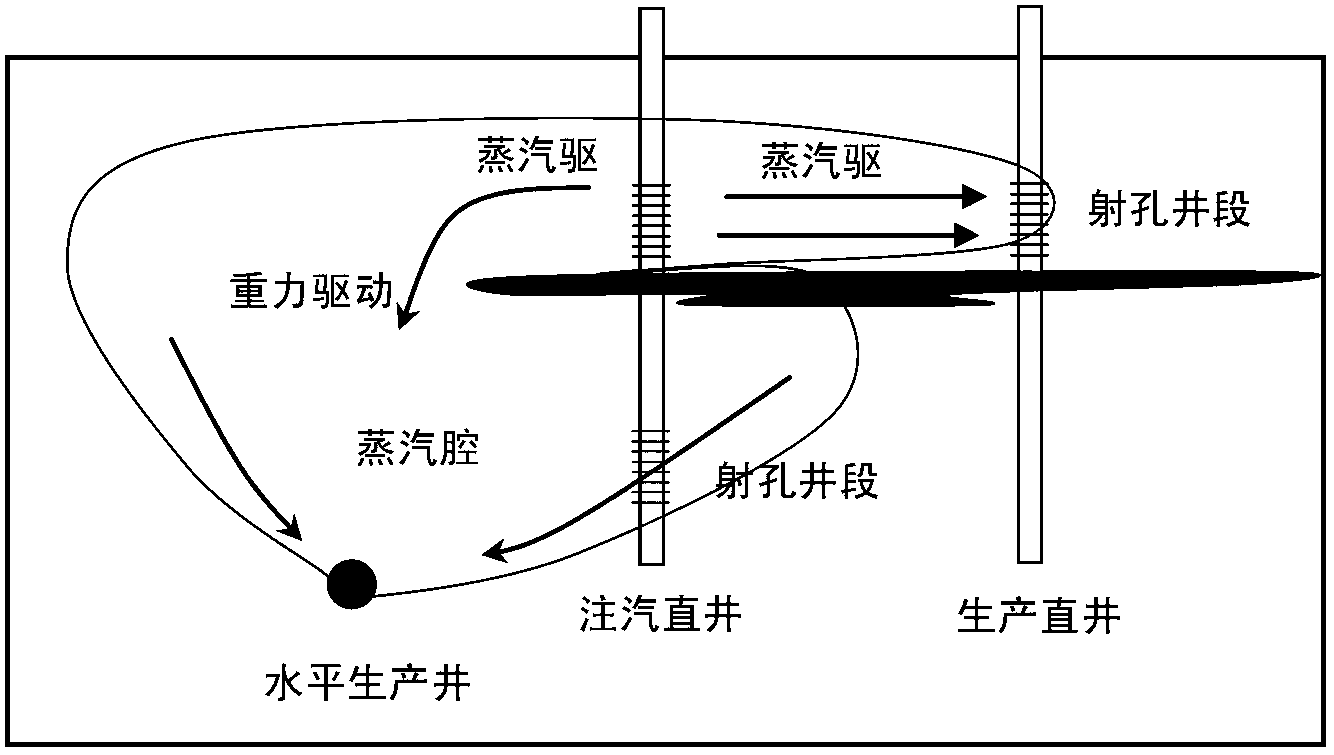

[0039] Example 1: The VI sand body of oil layer in an oilfield is a thick-bedded ordinary heavy oil reservoir, the viscosity of degassed crude oil at 50°C is 2284.2mPa.s, the average thickness of the oil layer is 38.89m, and interlayers are generally developed in the oil layer, with an average thickness of 2.4m , the main component is argillaceous siltstone. The average steam huff and puff of vertical wells in this reservoir has reached 7 cycles, the formation pressure has dropped from the original value of 16.1MPa to 1.0MPa, and the cycle oil production and oil-gas ratio have decreased. In view of the geological characteristics, crude oil properties and development status of the reservoir, the development is carried out by the combination of vertical wells and horizontal wells according to the following steps:

[0040] (1) Perform rough screening according to reservoir geological parameters and fluid characteristics;

[0041] (2) Since the thickness of the continuous oil lay...

example 2

[0047] Example 2: The sand body of an oil layer in an oilfield is a thick-bedded ordinary heavy oil reservoir, the depth of the reservoir is 750-800m, the viscosity of degassed crude oil at 50°C is 1680mPa.s, the average thickness of the oil layer is 31m, and interlayers are generally developed in the oil layer , with an average thickness of 1.7m, mainly argillaceous siltstone. The average steam huff and puff of vertical wells in this reservoir has reached 7 cycles, the formation pressure has dropped from the original value of 7.35MPa to 1.5MPa, and the cycle oil production and oil-gas ratio have decreased. According to the geological characteristics, crude oil properties and development status of the reservoir, the development is carried out by the combination of vertical wells and horizontal wells according to the following steps.

[0048] (1) Perform rough screening according to reservoir geological parameters and fluid characteristics;

[0049] (2) Since the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com