Thermochemistry auxiliary reinforced steam flooding method

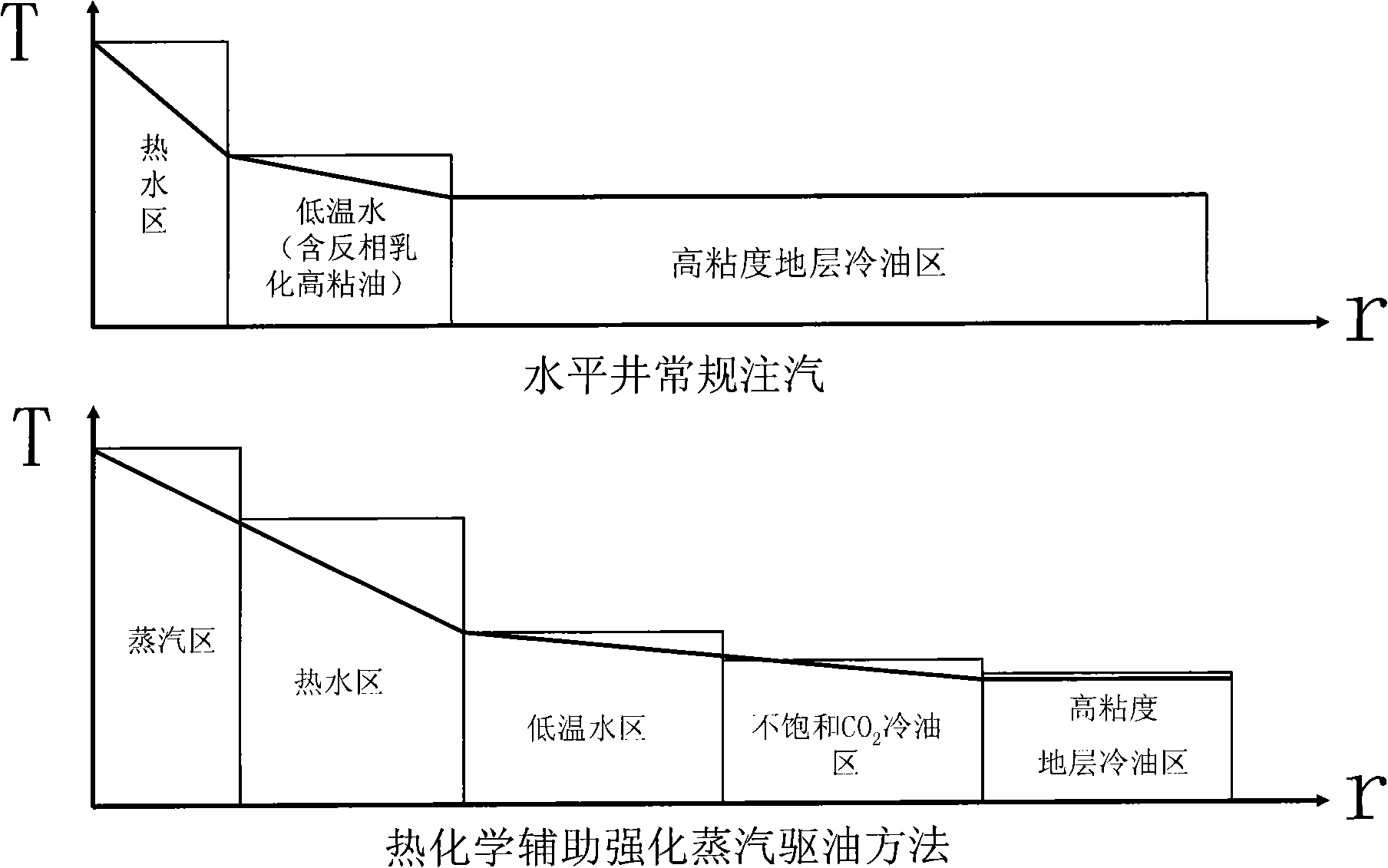

A steam flooding and thermochemical technology, applied in earthwork drilling, production fluid, wellbore/well components, etc., can solve problems such as increased formation heat loss, small steam heat sweep range, and impact on mining effects, etc., to increase reserves Production degree and recovery factor, increase steam heat sweep range, and achieve economical and effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

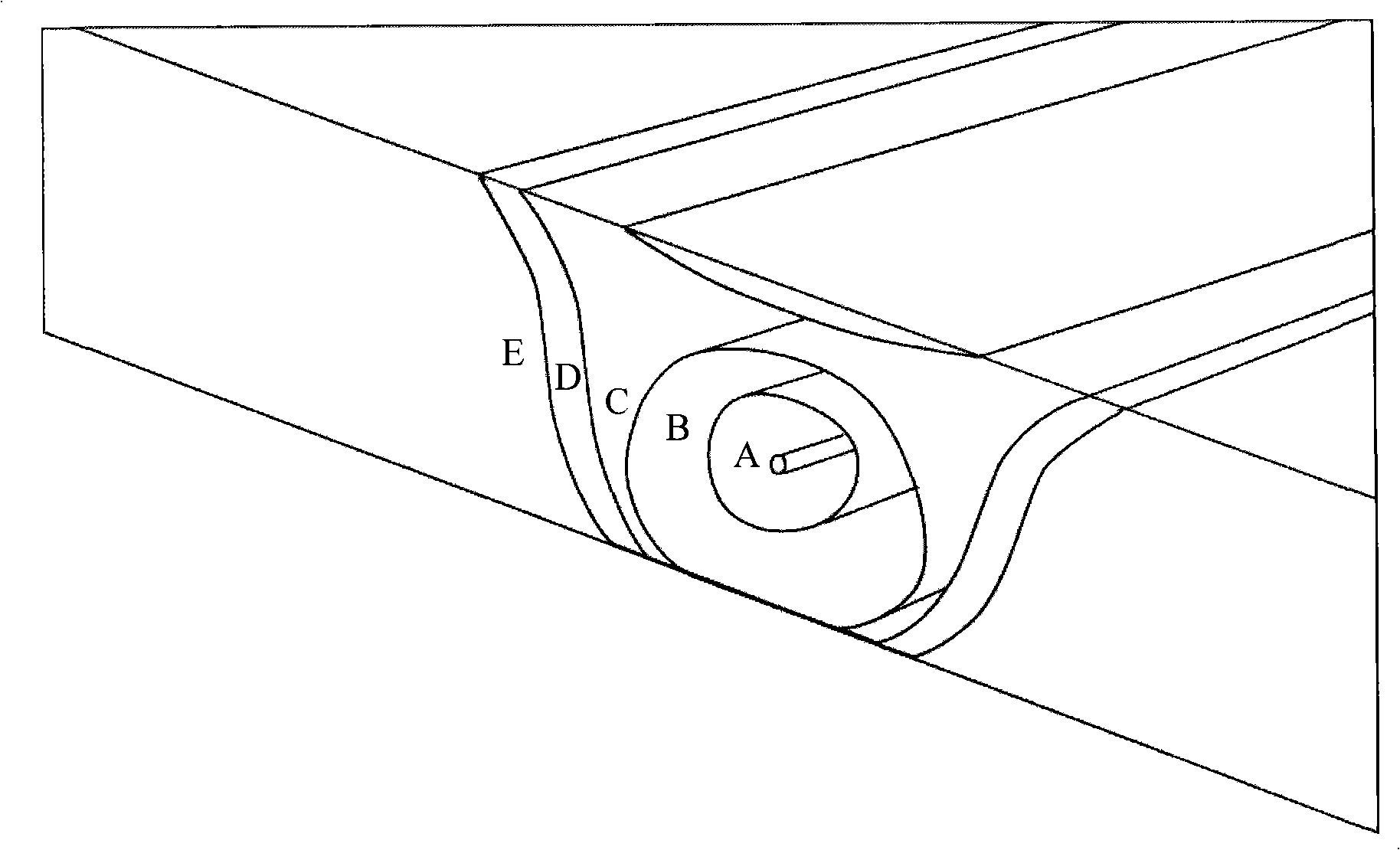

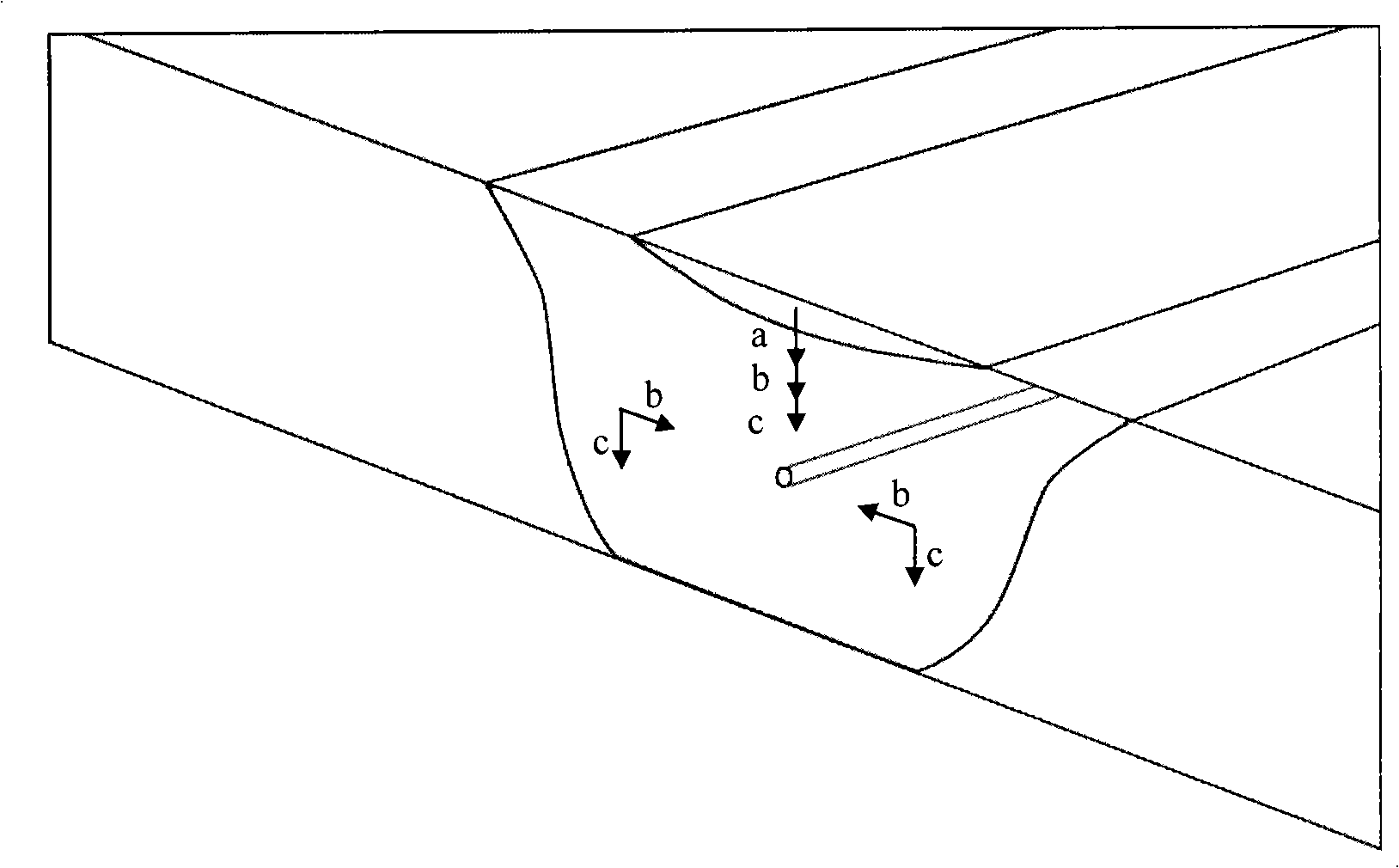

Method used

Image

Examples

Embodiment 1

[0045] Example 1: A block with an oil-bearing area of 5.2km 2 , proven oil reserves in place 1825×10 4 Ton. The main oil-bearing formation is Shashangshang, the buried depth of the oil layer is 1280-1425m, the thickness of the oil layer is 4-12m, the porosity is 32.8-34.4%, and the permeability is 4913-7280×10 -3 μm 2 . At 80°C, the viscosity of crude oil is 9024~60987mPa.s (the viscosity of crude oil at 50°C is greater than 20×10 4 mPa.s, up to 100×10 4 mPa.s), which is a medium-deep ultra-heavy oil reservoir with strong edge and bottom water effects. During the 20 years from the discovery of this block in 1984 to 2004, a total of 10 vertical wells and 1 horizontal well were drilled. 2 Auxiliary steam huff and puff, SAGD pilot test and other work, due to the high viscosity of crude oil, the deep burial of oil layers and the influence of edge and bottom water, the periodic development effect is poor, and the reserves have not been developed.

[0046] In view of the ge...

Embodiment 2

[0068] Example 2: The oil-bearing area of a certain block is 3.4km 2 , proven geological reserves 1977×10 4 t, the main oil-bearing formation is Shashang 3, the reservoir depth is 1300-1500m, the porosity is 24-31%, and the permeability is 600-1000×10 -3 μm 2 , the viscosity of ground degassed crude oil at 50℃ is 15×10 4 ~20×10 4 mPa.s, is a medium-deep ultra-heavy oil reservoir with strong edge and bottom water. During the 23 years since the discovery of this block in 1982 to 2005, a total of 5 vertical wells and 1 horizontal well have been drilled, and various mining methods have been adopted to assist subcritical boiler steam injection, high-pressure filling sand control, and fracturing sand control. However, due to the deep burial of oil layers, high steam injection pressure, poor quality of steam injection, and poor mining effect, the block cannot be industrialized.

[0069] According to the geological characteristics of the reservoir, the properties of crude oil a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com